This is not a detailed look at the life and times of D1702 - D1706, rather a brief glimpse at the 12LVA24 engines that were installed in these locomotives, and which should have had a bright future, but did not.

Significant dates in the timeline of D1702 - D1706 and the Sulzer LVA24 engine in service on British Railways and elsewhere.

1927 Sulzer discontinue development on 'V' engine design.

1958 The SNCF look to Sulzer for higher output, lighter engines than the LDA series, the LVA24 series has its beginning.

1960 SNCF 040 DG class 501 & 502 enter service with 1,750hp 8LVA24 engines.

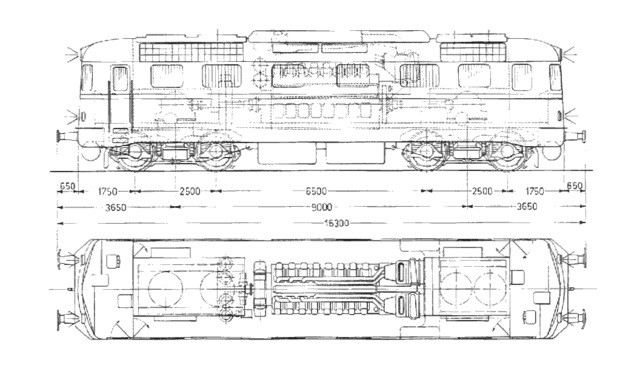

1962 Brush Electrical Engineering Co. Loughborough receive order for Type 4's D1682 - D1706

1963 SNCF 68000 class enter service with 2,620/2,650hp 12LVA24 engines.

1964 January - D1700 & D1701 enter service fitted with standard 12LDA28C engines.

1965 September - D1703 enters service equipped with a 12LVA24 engine.

1965 November & December - D1702, D1705 & D1706 enter service.

1965 Brush/Clayton supply ten 12LVA24 powered locomotives to Cuba.

1966 July - D1704, the last of the 12LVA24 powered Type 4's enters service.

1968 January - HS4000 Kestrel fitted with an 16LVA24 engine is unveiled at Loughborough.

1968 July - D1702 stopped at Crewe Works, for conversion back to a normal 12LDA28C powered locomotive.

1970 Three more reach Crewe Works, D1703 (Feb), D1706 (Mar) & D1705 (Nov) for conversion.

1970 Development of the LVA range is discontinued by Sulzer.

1971 January - the last 12LVA24 powered Type 4, D1704 arrives at Crewe for conversion.

1971 July - HS4000 Kestrel is exported to Russia.

The LD series of engines had been introduced in the early 1930's and after almost thirty years of service and development had reached the limit of their design. This was perhaps very obvious in light of the challenges that faced the 12LDA28B & 12LDA28C series of engines operating on British Railways. The other major operators of similar engines had kept the engine rating in the 2000/2100hp range, thus avoiding many of the issues experienced by British Railways.

Sulzer had discontinued development of the 'V' engine design in the late 1920's. The configuration of 'V' engines places high stresses on crankshaft and big end bearings - the technology to produce these had not kept pace with the increased outputs being demanded during the 1920's. Since Sulzer's 'bread & butter' came from its inline marine engines where space and weight were not so critical as for railway purposes it continued development of these vertical inline designs. The inline double bank engine was Sulzer's answer to increased output for locomotives without the need for development of lengthy crankshafts and other components. Just prior to World War Two the railways in France and Rumania took delivery of locomotives equipped with double bank engines, these were the forerunners of the locomotives that would see major orders in the 1950's for the 12LDA28 series.

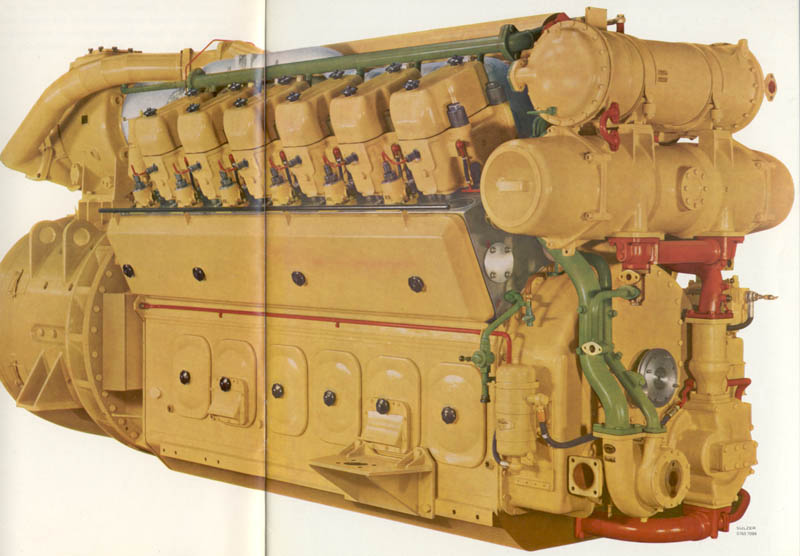

During the late 1950's the SNCF approached Sulzer with regard to the possibility of obtaining an engine producing greater output than the LDA series. Increased output from the existing range of engines meant compromising axle load limits and the availability of space withing the European loading gauge. This request and subsequent development led to a completely new and more conventional V-engine being designed and built in Switzerland, designated the LVA24 engine which had a higher cylinder output than the LDA28 unit. The Sulzer plant in France then built two eight cylinder 1,750hp 8LVA28's for installation in SNCF locomotives 040 DG class numbered 501 & 502, entering service during 1960.

Following this a substantial number of 12 cylinder engines were constructed and installed in the SNCF 68000 series locomotives. British Railways were watching these developments with interest, in particular JF Harrison, the Chief Officer for Locomotive Construction & Maintenance, who had been heavily involved with the British Transport Commission decision to have Sulzer engines installed in parts of the Modernisation Plan fleet. To evaluate the new engines five 2,650hp 12LVA24's were delivered for installation in Brush Type 4's D1702 - D1706, the last five from an order covering D1682 - D1706. These five locomotives were delayed in entering service as they awaited their engines, the delay was at least eighteen months.

The locomotives were initially allocated to Tinsley, where resident specialist Sulzer Service Engineers (Hans Spaltenstein and others) could monitor them. They were assigned to coal train operations out of Shirebrook. Routine running repairs could be handled at Tinsley, but repairs of a more serious nature were handled at Crewe Works, where other Sulzer specialist staff were available. As the locomotives started to accumulate running hours a number of faults came to the surface, but these were of a minor nature and were quickly diagnosed and modifications made. However it would be the visits to the main workshops that would lead to major problems with the engines.

During a routine big-end bearing examination at Works, the opportunity was taken to change the bearings because they showed signs of wear and would probably not last until the next scheduled major repair. The big-end bearing consisted of an upper and a lower shell which were not interchangeable, and as such the lower shell only had a locating hole on the back which lined up with a dowel on the lower cap, thus ensuring that the bearings could not be interchanged. This dowel formed no other function in the running of the bearings and hence became known as the ‘idiot’ pin! The fitting of the con-rod involved lowering the piston and rod with its upper shell in place, down onto the crankshaft. The fitter then fitted the lower shell into a tool which looked like a bearing cap - complete with dowel pin, attached to a long arm. So we now have the fitter reaching across the crankcase with this heavy tool at arms length and offering it up to the crankshaft to line up with the edges of the upper shell. He then lowers the tool leaving the bearing shell held temporarily in place by an oil film, before finally fitting the big-end cap.

Within a fairly short time, one by one, the locomotives that had been worked on failed in a variety of disastrous ways - crankcase explosions, thrown connecting rods, crankshaft scoring, etc. Quite understandably British Railways became frustrated with all this loss of service, down time and Works expense and demanded that Sulzer find solutions. Oil samples were taken, bearing surfaces and manufacturing tolerances were checked and even Crewe Works cleanliness came under scrutiny. Nothing stood out as being the root of the cause of the on-going failures and the decision was taken to withdraw all the locomotives from service and send them to Crewe Works to have 12LDA28C engines fitted.

A short while later on the prototype 4,000hp locomotive HS4000 ‘Kestrel’ fitted with a 16LVA24 engine was running on BR and it too suffered a crankshaft failure shortly after having some work done on the big-end bearings at Tinsley, the reputation of this engine was getting worse and worse. By shear coincidence, at about this time, a senior engineer from Sulzer UK paid a courtesy visit to the SNCF workshops and saw some bearings from a 12LVA24 engine on the bench and noticed that the wear pattern was different from those in the UK, and asked the staff why this was so. Their reply was startling! They stated that this wear pattern was normal after a long period of service and they had not experienced any major engine failures and that furthermore as a shop-floor change of practice, they had removed the famous ’idiot pin’ because all the fitters knew the difference between the upper and lower bearing shells! They remarked that this had been mentioned to the Service Manager from Switzerland, but clearly the information was never communicated to other operators. With the engineers and staff in the UK following the Sulzer procedure manual to the letter, the slightly imperfectly manufactured tool doomed the LVA24s operated in the UK.

During the rebuild of the ‘Kestrel’engine this pin was removed, but the Sulzer people at Tinsley and Crewe wanted to get to the bottom of it because their fitting expertise had been brought into question. It was found that the locating pin in the lower bearing fitting tool was about ½ mm out of position, i.e. the tool had been incorrectly made. The penny then dropped. This was the only tool in the UK and was used at both Tinsley and Crewe; it was realised that with the heavy tool at arm’s length inside the crankcase, the fitter could not feel the pin fouling on the back of the bearing instead of locating cleanly in its hole. Thus the lower shell was not correctly located and a high spot was being pushed up on the surface of the bearing caused by the ill fitting pin. A high spot will quickly heat up, leading to rapid wear and material transfer from the bearing to the crankshaft; complete failure will occur in a short space of time due to break up of the bearing, debris in the oil will contaminate the other bearings, the cylinder liners and pistons.

There is an interesting post-script that has come to mind regarding the reputation of the UK engineers involved with the overhaul of the 16LVA24 Kestrel engine prior to its dispatch to Russia. The Swiss parent company were so concerned about the failure of the crankshaft in this engine, following so closely after the failures on the Class 48 engines, that they sent a supervising engineer (Willi Schoop) from Switzerland to oversee the repair of Kestrel’s engine at the Vickers works at Barrow-in-Furness. (Edwin Wild made all the arrangements between Sulzer and Vickers.) The locomotive was positioned on the dock-side at Vickers so that their massive Goliath crane could be used to lift out the engine as a single unit. Time was of the essence because this dock was normally used for fitting out submarines and in earlier years the crane lifted boats in and out of the water in one piece! As occupation of the dock had to be kept to a strict timetable, the Sulzer staff worked in round-the-clock shifts, something which the Victoria Park Hotel never really got to grips with, and hence the work was done by whoever was on shift at the time. The supreme irony of all this is that when the time came to install the pistons and big-end bearings (without their idiot-pins) the work was supervised by the same UK engineers who had been so heavily criticised previously, because the Swiss engineer was off shift at the time!

It was too late to save the removal of the five 12LVA24 engines, but in a strange twist Kestrel’s engine (without the pin) ran satisfactorily and because BR had no requirement for a single 4000hp locomotive, it was sold to Russia and ran for a considerable time without any major engine problems. Sulzer and Brush lost track of ‘Kestrel’ after a few years, but no doubt the technology was copied and used to advantage by the Soviets!

Meanwhile the reputation of the Sulzer and BR engineers in the UK had been restored and the damaged 12LVA24 engines were purchased by Sulzer France, refurbished and sold to SNCF for their locomotives.

Retrospect is a wonderful thing and if these LVA24 engines had not suffered such catastrophic failures, it is almost certain that they would have been specified for the later Class 50 locomotivess. In this respect the licence for the LVA24 engine was bought by English Electric (later Rustons) who used many of the design features in their CSVT engine and promptly dropped the Sulzer licence, even though at their insistence a 16LVA24 engine with a cast cylinder block had passed a full 840 hour test in Switzerland! The Class 50 went ahead with the Ruston engine, as did the Classes 56 & 58. The Class 60 was fitted with a Mirrlees 8MB275 engine, but that is another different but interesting story. At the time of tendering for the Class 58s, Sulzer, Ruston & Mirlees offered solutions. Mirlees won the contract but ended up losing a lot of money on the limited contract. The decision of Sulzer, Winterthur to withdrawn from the bidding because of costs and cuts to the Class 58 fleet took place on the day that a group of BR technical staff arrived at Zurich airport for meetings in Winterthur! It was left to the manager of Sulzer, London to break the news that night over dinner.

The LVA24 was discontinued for traction after the sale of the licence, but it had a big influence on the very successful Sulzer A25 engine which was used in great numbers as a marine auxiliary engine in many deep-sea ships, ferries and cruise ships and as a propulsion engine in motor-barges, tugs, service-craft and land based power stations. In the marine application the A25's would run at constant speed and get a much easier life than when used for traction. Diesel engines do not like cyclic operation because of the fluctuating thermal and mechanical stresses - the majority of the engine problems came from this fundamental principle. The design of the two engines is so similar that one of the UK engineers (Geoff McEwen), involved with D1702 - D1706 and HS4000 Kestrel needed a minimum amount of training before he was familiar with the A25 engine! Hindsight is a wonderful thing but it does prompt a whole lot of other questions.

One offshoot of the LVA series as it transitioned into the A25 series was its brief sortie into the American market. A number of railroads had approached the manager of Sulzer, New York asking for locomotive engines to break the monopoly of General Electric and General Motors and the high prices charged for their spare parts. Morrison Knudsen assisted in fitting 6A25 and 12AV25 engines into locomotives from the Union Pacific, Rock Island Line and Santa Fe railroads. Engineers from Switzerland were sent to oversee the whole project. In service the locomotives encountered conditions somewhat different from European operations, principally long trains headed by multiple locomotives, long tunnels and great distances between depots when failures occurred.

The combination of the above meant that in long tunnels, all except the leading locomotive were taking hot dirty air into the intakes. Serious overheating was the result with burnt valves and scuffed cylinder liners etc. In the UK a much better valve material had been developed for BR's LDA28 engines, but Winterthur did not immediately apply it to the A25 engine, because in marine service it wasn't necessary. The US railroads lost patience, General Electric & General Motors saw sense and lowered their prices and Sulzer withdrew with their tails between their legs and big bills to pay!

![]()

Later thoughts from Chris Brown

As mentioned previously,the LVA24 engine took over from the LDA28, but Winterthur were leaning more and more to the marine side where the smaller engines like the A25 are used for auxiliary power generation. They run at constant speed and get a much easier life than when used for traction.The LVA24 licence was sold to English Electric in 1968 and the Traction Division was merged back into the Marine Division, but engineering support for the LDA28 was still forthcoming. I must stress this in case anyone got the impression that we just abandoned BR and left them to get on with the LDA28. In fact, up to my retirement in 1998, we were still supplying spares for the dwindling number of Class 47s and Geoff McEwen still had contacts through his own company right up to his passing.

The A25 experience has been covered previously and one final factor virtually finished our involvement in diesel traction. Pairs of hands in Switzerland are very expensive so today all engines are made under licence. Winterthur used to build about 5% of marine engines in order to retain a nucleus of manufacturing experience and to have engines for development purposes. However,because of commercial pressures engines are developed in conjunction with licencees and test engines are built in Italy but installed in the Diesel Technology Centre in Ober Winterthur. The old main works in the town is closed and many staff have left.

A bit of a saga, but I saw 32 years of the Traction Division because I was MD of the UK operation, but from 1980 my main effort was directed towards the marine side. There is still a small band of old Tractionites still around in Winterthur and from time to time contact is made. Can you imagine bringing dozens of engineers from Sulzer, many of them barely out of apprenticeship, giving them a typewriter and sending them off to various BR workshops and depots with instructions to write reports about LDA28 engines? They were halcyon days and many of these guys married British ladies and went back to Switzerland with them and continued working for Sulzer in various Divisions. One man who did just this is still working for Diesel, albeit in Cyprus!

![]()

LVA Production 1960 - 1972

The number of LVA series engines produced was not large, a total of 109 of which most were for use in locomotives. A brief summary below records the usage of the engines built - the number in parentheses indicates the number produced for each line item.

TRACTION

1960 France SNCF (2) 8LVA24

1963 - 1967 France SNCF (83) 12LVA24 including 3 spare

1965 Cuba (11) 12LVA24 including 1 spare

1965 United Kingdom (5) 12LVA24

1967 United Kingdom (1) 16LVA24

STATIONARY

1968 France USINOR Dunkerque (1) 16LVA24

1969 Strasbourg EDF (1) 8LVA24

1970 EW Schaffhausen (2) 16LVA24

1970 Switzerland Sulzer Bros (1) 12LVA24

MARINE (PROPULSION)

1967 France fishing boat 'Etel' (1) 8LVA24

MARINE (AUXILIARY)

1967 France dredger 'Ambiteuse' (1) 12LVA24

![]()

Thoughts from Steve Palmano posted to the World Diesel Loco Group site in 2022 with regard to the post LVA era.

One topic that I have not previously looked at very closely is English Electric’s brief dalliance with the Sulzer LVA24 engine. However, a recent read of the paper “The 12 LVA 24 Engines in the Class 48 Locomotives in Great Britain - A Diesel Engine Story written by Chris Brooks in October 2007” has prompted a more detailed consideration.

This does have some bearing on events in the export market, as I’ll address later.

Early on in the paper it was said:

Four 12LVA24 engines were subsequently fitted in some Class 47 locos at Crewe and were numbered 1702-1705, of which the latter is at the Great Central Railway in Loughborough where, although retaining this number, it was actually reverted to a 12LDA28-C engine when the Class 48 was discontinued. Retrospect is a wonderful thing and if these LVA24 engines had not suffered such catastrophic failures, it is almost certain that they would have been specified for the later Class 50 locos. In this respect, the licence for the LVA24 engine was bought by English Electric who used many of the design features in their CSVT engine and promptly dropped the Sulzer licence even though at their insistence, a 16LVA24 engine with a cast cylinder block, had passed a full 840 hour test in Switzerland!

In particular the suggestion that absent the Class 48 failures, the LVA24 engine would have been used in the BR Class 50 does not accord with any of the writings about this locomotive that I have seen. Rather, the conventional wisdom is that it [the class 50] was an outgrowth of the conspicuously successful EE DP2 prototype, whose key feature was its EE 16CSVT Mk II engine.

In his book “Class 50s at Work”, author John Vaughn said:

I now return to early 1965 and the decision facing the BRB regarding any order for further Type 4s. This decision inevitably involved internal politics. Influential Board operating staff remained unconvinced that the Regional pressure for the locomotives was justified, believing that the West Coast and other needs could be met from existing orders. The Regional lobby, however, was strong. With the Sulzer troubles emerging, its spokesmen took the opportunity to press yet again for a production version of DP2, on the theme that BR's eggs should not have been concentrated in the Sulzer-engined Type 4 basket. Finally, an enquiry was put out at the request of the Regional lobby. The number of units which might be required was undecided, so tenders were invited for either 50 or 110 units. At the BRB's request, these were not only for more Brush/Sulzers, but for Brush locomotives with English Electric engines, and also for entirely English Electric produced 2,700bhp units. English Electric submitted its tender on 2 June 1965, and the validity of these tenders expired around the end of July.

It is conceivable that the Brush/Sulzer combination could have included the Sulzer 12LVA24 engine, either as an alternative to or in place of the 12LDA28. But the fact that two of the three options specified the EE engine suggests that this was the “front runner”. At the time the 12LDA28 engine was in trouble, and BRB was no doubt mindful of its recent experience with the Mirrlees JVST12 engine in the class 30 fleet. And although the 12LVA24 engine was in service in France, BRB did not yet have any experience with it. The five-member Class 48, fitted with this engine, were yet to enter service, this happening in the 1965 September through 1966 July period according to Webb, writing in “Sulzer Diesel Locomotives of British Rail”.

Vaughn went on to say:

The December 1965 issue of Modern Railways revealed exclusively that an order was to be placed by the BRB, with English Electric, for units based on DP2. The number involved would not be under 50, and might be as high as 70. The February 1966 edition of the same journal disclosed that the number would, indeed, be 50.

Thus the Class 50 order would have been placed before all of the Class 48 were in service, and well before any problems were seen with the 12LVA24 engine. It could be said that on the basis of the information available at the time, BRB made the best choice for what became the Class 50.

Tufnell, writing in “The Diesel Impact on British Rail”, noted that the collaboration between EE and Sulzer began in 1966 August. This was well after the Class 50 order had been placed, and probably after EE had ordered the 16CSVT engines from Vulcan, as well as other long lead-time items. It would not have been impossible for BRB to ask EE to build a locomotive with a third-party engine, but that would have been very unusual for EE at the time, and there is no evidence that that possibility was considered.

One could say that the BRB choice of engine (and supplier) for the Class 50 was quite separate – and separated in time – from EE’s collaboration with Sulzer. Chris Brooks might have somewhat conflated the two.

Of EE’s decision to engage with Sulzer, Tufnell said:

In an endeavour to obtain a share of the really high-power locomotive market (4000 hp and more) that was thought to be impending, a strong collaboration began between English Electric and Sulzer. The idea was that English Electric, then about to take over Ruston and Hornsby (including Paxman) would produce the new Sulzer LVA24 range which was, at that stage, virtually untried. The lower end of the power range would be catered for by Paxman 'Ventura' range and the 10 in (254 mm) bore RK/V which was suffering from lack of development would be dropped or possibly retained for industrial applications only. Five of these twelve-cylinder Sulzer LVA24 engines had just gone into service in the Brush Type 4 (Class 48) locomotives at a rating of 2600 hp, and fifty nine were in service on the SNCF. Brush were considering the building of a locomotive to embody one of the sixteen-cylinder versions, at 4000 hp.

Although it is not completely clear, it does look as if the Ruston & Hornsby (R&H) folks may have had some say in events even before the takeover. One may see how the newer LVA24 design might have appealed to R&H, who at the time leaned towards underslung crankshafts and fabricated crankcases, to which form the Sulzer-built LVA24 conformed.

The actual takeover of R&H happened in 1966 October, and for a few years thereafter, EE Diesels was dominated by R&H thinking.

Two more observations by Tufnell are pertinent:

A joint collaborative effort with English Electric Diesels to produce this LVA range in the UK using a cast iron meehanite crankcase designed by English Electric fell through after considerable expenditure. Sulzer submitted a sixteen-cylinder version to a 3500 hr UIC homologation test, which was successfully achieved only to find inclusions in the crankshaft on strip down. Attempts to sell the engine for traction and industrial purposes came to nought and the project was dropped.

And:

Unfortunately, for various reasons this last project did not work out at all well, and after spending a lot of time and money the RK had to be hastily reinstated and uprated. This time a thorough job was made, and the new design emerged as the present Mk III version with an output of 262 hp per cylinder at 900 rev/min. This was available from 1969,..

Clearly, EE’s strong established preference for the cast iron crankcase prevailed over the legacy-R&H viewpoint, and developing this would have been a major exercise and cost. That could be taken as an indication that EE was committed to the project. But it would seem that neither Sulzer nor EE were able to sell the engine. That would have had little to do with EE’s involvement, which would not have inhibited Sulzer’s own sales efforts. Rather, the market for a new high output medium-speed engine was just not there.

EE may not have withdrawn from the agreement with Sulzer before starting work on the upgraded RK engine, though. Quite possibly EE’s non-railway customers were looking for an improved version of this engine. And the thinking was that it might be retained for those applications anyway. At least according to the EE entry in Jane’s 1969-70, it was offering both the RK Mk III and the LVA24:

CCM Sulzer, France, was also offering the LVA24 at the same time, as also recorded in Jane’s 1969-70.

According to Tufnell, the UIC 100 hour test was run in 1967 March, and the 850 hour ORE test in July through August of the same year. So it looks as if there had been a year, perhaps two years when vigorous sales efforts would have been made by both EE and Sulzer.

The Jane’s entry for CCM-Sulzer indicated that it was a Nantes-built 16LVA24 engine that was used for the UIC and ORE tests. This is unlikely to have had a cast frame, given that the latter was an EE development, whereas the Sulzer original had a fabricated frame, although Chris Brooks stated that the engine tested was a cast frame version. Whether the UIC and ORE testing was of that much import to EE’s customers is unknown, but it does not seem to have been an issue with the RK engines. Rather it was more likely to have been done for the potential European market.

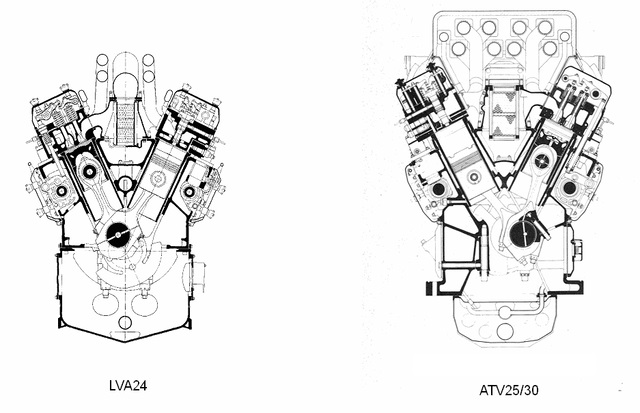

In 1968 April, EE and Sulzer published a joint IME paper about this engine, namely “Some Aspects of the Development of The LVA24 Traction Engine”, by A. Dolenc (Sulzer) and R. Lees (EE). This discussed various aspects of the engine, including the combustion system, the pistons and the structure. Mentioned was a piston rotation mechanism, not part of the original LVA24 design, but a Sulzer idea that it had used for its Z40 marine engine. The cross-sectional diagram included therein looks as if it were for the cast crankcase version, as it was slightly different to the diagram shown in the Sulzer LVA24 brochure.

It does not look as if any major aspects of the RK Mk III design were derived from the LVA24 engine. In fact most of what was done in terms of upgrading from the Mk II were changes that were known to be required before the LVA24 interlude, but had not been done in part because they were not seen as needed for the non-railway applications, so that those in EE selling into those markets resisted them as incurring unwanted extra costs. In fact the auxiliary drive upgrade had been implemented for the Australian version of the 12SVT and 12CSVT Mk II engines back in 1964. EE may well have introduced some refinements into the MK III engine that had been inspired by its work with the LVA24, but that was probably not precluded under the terms of the licence agreement.

The effort put into the Mk III RK was indicative of a company that planned on staying in the locomotive business. However, the GEC takeover and the subsequent formation of EE-AEI Traction, initially dominated by AEI thinking, essentially killed any chance of that.

Regarding EE’s export business, the Mk III engine era represented the tail end of it as far as complete EE-built locomotives were concerned. It was mostly repeat business with customers who already had fleets based upon the RK Mk II engine, the latter being used in new builds through to 1972. Of the final customers, it seems unlikely that those in Australia, particularly Queensland Railways, Western Australian Government Railways and Tasmanian Government Railways would have been prepared to embrace a completely new engine, namely the 12LVA24, in place of the familiar 12CSVT. If the 12LVA24 had been the only choice, I think that the most likely outcome is that EE would not have obtained the late orders from these established customers. And KTM Malaysia probably based its choice of the 22 class with 8CSVT Mk III engine on the excellent service history of its 20 class with the 12SVT Mk II engine.

In a more general sense, it probably would have been quite a risky move for EE to swing from the RK to the LVA24 engine given that its major competitors, EMD, GE and MLW were all offering improved versions of long-standing and very familiar designs.

In respect of the Australian market, Brush had endeavoured to gain entry in the mid-1960s with Sulzer LVA24-powered designs, but there were no takers; see: https://groups.io/g/World-Diesel-Loco/message/12870. REMOVE REMOVE REMOVE

AEI was a potential outlet for the LVA24 engine, and apparently some work had been done on fitting the 8LVA24 to the Zambesi design in place of the 6LDA28 engine, but there were no takers. It is not clear as to wherefrom the LVA24 engines would have been sourced in that case. Whilst CCM-Sulzer was building that engine, French sourcing might not have been acceptable for AEI export orders that had some British Government backing on the financial side. Perhaps EE sourcing was envisaged, with EE nominally building engines for Sulzer UK who then onsold to AEI. Once EE was taken over by GEC, as AEI already had been, then EE sourcing would have been “in-house”, but by then the fate of the EE LVA24 project might already have been determined. Still, it is not difficult to imagine that the legacy AEI faction, who appeared to have had the upper hand initially in EE-AEI, would have opted for the LVA24 over the RK had the matter still been open.

The failure of the EE collaboration would not have stopped Sulzer from staying in the locomotive engine business had it chosen to do so, but evidently the prospects were just not good enough. Sulzer may have seen EE, as an established and reasonably successful locomotive builder, as being as good an outlet for its locomotive engines as it was likely to find. The fact that EE was evidently unable to drum up a sustaining level of interest in the LVA24 engine may well have informed to some extent Sulzer’s decision to exit the locomotive market.

On balance I think it would be difficult to draw a robust conclusion that the failure of the LVA24 engine to gain a material share of the market was attributable to EE’s involvement, or that EE obtained the licence simply in order to obtain some technology that it could then apply to its RK series. Rather the joint effort was potentially mutually beneficial; the apparent problem was that few potential customers were interested in a new engine. I suspect that even had enough business been found to continue the project, EE still would have found it necessary to continue – and update – the RK series in order to meet the needs of existing customers who did not want a change of engine type.

Had Sulzer nonetheless continued to offer the LVA24 engine without EE’s involvement, then although it was not in the frame for the BR class 50, it might have been a candidate for later projects such as the class 56, bearing in mind that the concerns that had arisen with the class 48 installation had been resolved. But that would almost certainly have required that the engines be built under licence in the UK. Whether Vickers, who had built the LDA28 series. would still have been a candidate I do not know. I imagine that it could well have seen the EE collaboration as signalling the end of its tenancy.

If nothing else, the EE interlude added another element to the rather diverse experience of Sulzer (UK).

Its initial post-WWII business was with CIE, where it was the powertrain contractor for the latter’s own-build prototypes. MetroVick (MV) was the electrical equipment subcontractor, to Sulzer, but I suspect that it was chosen by CIE. That was probably before the formation of the tripartite alliance of Sulzer, BRCW and Crompton Parkinson (CP). The alliance produced the standard export design built for CR and SLDC, and also the BR classes 26 and 33.

The CIE B class was something of a hybrid. This class used the 12 Sulzer engines (and presumably the MV electrical equipment) that had been built for CIE’s stillborn twin-engined mainline project. Here I imagine that MV, now occupied with the large order for the CIE Crossley-engined A and C classes, would have been reluctant to also take on the B. Sulzer may well have been instrumental in bringing in its then partner BRCW to undertake the mechanical design and building.

Sulzer did very well with BR, in part from a strong LMR preference for its engines. But the downside was that it had to accept the use of its engines in BR own-design locomotives that were probably not as good as the industry could produce. (Apparently Sulzer did not much like the class 44 et al.) In the case of the class 44, Sulzer was the designated powertrain supplier and apparently chose its existing partner, CP, for the electrical equipment. For the class 24, whilst BR had chosen the Sulzer engine, it had also chosen BTH as the electrical supplier, and the primary powertrain contractor. Thus Sulzer was now working with a third UK equipment supplier, bearing in mind that BTH and MV, although both owned by AEI, were at that time functionally separate.

Sulzer’s preferred electrical equipment partner, CP, struggled with production. The net result was that for the repeat class 26 business (as class 27), GEC became the electrical equipment supplier, and for the repeat class 45 business (as class 46) Brush became the electrical equipment supplier. So by the early 1960s, Sulzer (UK) had worked with all of the UK traction electrical equipment suppliers except EE. On the mechanical side, it had worked with CIE and BR for their own-builds, and with BRCW.

BRCW could certainly design and build a good locomotive, but never reached critical mass in terms of market share, and in any event was taken down by the failure of its parent company BSA. CP was absorbed by Hawker Siddeley (who by then owned Brush) in 1968. CP was regarded as having a good product. the BR class 45, with CP equipment was generally reckoned to be better than the very similar class 46, with Brush equipment.

Sulzer’s association with Brush bore very little fruit in the export market. Brush’s in-house Mirrlees engine was anyway, before its failure, its first choice for most of the export business on offer, and after its failure, Brush turned to the EE RK when bidding for medium-power export business, although as noted, it did attempt to obtain LVA24 business in Australia.

Effectively the Sulzer/BRCW/AEI tripartite superseded the previous Sulzer/CP/BRCW combination, and produced the “Lion” prototype, which to a large extent grew out of Sulzer’s dislike of the BR class 44/45/46.

Following the end of BRCW, the tripartite became Sulzer/AEI/Metro-Cammell (MC). For the export market, it was able to draw on aspects of the Sulzer/BRCW/CP standard design, and of the AEI (BH) BTH) Explorer prototype, and it did obtain some African business in the 1960s with the “Zambesi” type. Also, the Sulzer/AEI/SLM/Tulloch combination sold some locomotives in Australia. But those business fronts had petered out by 1969. Insofar as EE continued to sell into the African market until 1972, and into Australia until 1976, perhaps it could be said that it was not wrong to have stayed with the RK engine.

In respect of electrical equipment, Sulzer had its own set of requirements that suppliers were required to meet, including interfacing with its own engine governor and following its own load control precepts. But how it was done was left to the individual electrical equipment suppliers. Thus some, such as BTH and CP, used differential compounding to obtain steeply drooped main generator curves that dropped on to the standstill line at the desired place to provide current limiting. On the other hand, MV used shallower curves, and so employed current limit relays to provide the requisite individual notch limits.

The Zambesi cluster was interesting, in that the original version had legacy BTH equipment that was based upon GE precepts (which BTH was inclined to follow), but was not exactly the same. The NRC 1401 class and the CR NT had essentially the same equipment as AEI had developed for use on Alco locomotives, and so was very close to the GE original designs.

As far as I know, the Sulzer engine never met EE electrical equipment, in a production locomotive at least, something that would have happened had the LVA24 project not been aborted.

As to the LVA24 engine itself, it was a relatively modern design with an underslung crankshaft. It was though of the wet block type, which would probably have produced some sales resistance. Of the major competition, EMD and GE both offered dry-block engines. This form of construction allowed very rapid change of power assemblies, even on a hot engine, without the need to drain the coolant or to allow the engine to cool down. On the other hand, the Alco 251 was of the wet block type, and this was looked upon with significant disfavour by some railway systems, although perhaps a minority outside of North America. In favour of the LVA24, one could say that its 240 mm bore size was pitched about right, allowing more room for power growth than say the 229 mm bore of the established Alco and GE engines of the time. It is just a guess on my part, but if, during the 1960s, EE had its own thoughts as to how a new medium-speed engine should be configured, then it might well have opted to keep more-or-less to the RK bore size, say around 250 mm, with room for future growth, in a dry block, underslung crankshaft, cast frame configuration.

![]()

Australia - proposed locomotives using the Sulzer LVA range.

The failure of the Mirrlees engine in the Rhodesia Railways DE4 probably ended any chance that Brush could sell any more Brush-Mirrlees locomotives. In fact that turning point probably came earlier, with the failure of the same engine in the BR Class 30. Thus the Brush-Mirrlees story ended with the DE4. Thereafter Brush diesel-electric line-service locomotives were of necessity designed around third party engines. Although that is a separate story, nonetheless one aspect of it does connect with early 1950s failed effort to enter the Australian line-service diesel market with QR #1220, so is worth mentioning in brief.

In an article in the Australian magazine Railway Transportation (RT) for 1965 October, entitled “Higher Powered Diesels”, Brush was essentially promoting two “higher powered” diesel-electric locomotives for use in Australia. Whilst not involving the Mirrlees engine, the smaller of the two proposed locomotives, suitable for Cape gauge and upwards, was of the “90 ton” type. So it was a sequel to the abortive QR #1220 project. The larger locomotive was a very heavy type, aimed at the Western Australia mining roads.

The 90-ton locomotive was a Co-Co road switcher with a low short hood, evidently aimed at QR and perhaps WAGR and TGR. RT commented that it looked somewhat like the QR 1250. It was powered by a Sulzer 12LVA24 engine, producing 2500 hp. This was well above the level of the existing QR 90-ton fleet, which at that time did not go past 1650 hp (NTP basis). So the Brush proposal was certainly “higher powered” in comparison. In fact it anticipated the lift in power output that came in the early 1970s, for CMT-gauge locomotives in the 90- to 96-ton class. At 90 tons it would have been proximate to the later QR 2350 class, and at 96 tons to the QR 2100 class. It was available at weights up to 108 tons, at which level, and in standard gauge form, it would have been tantamount to a more powerful WAGR K class.

Whether any of the prospective customers were in 1965 yet ready to move to higher power in this weight class is unknown. On the basis of actual events, 1965 was around 7 years too early, although the timing of the move up the power scale might have been as much determined by availability (from existing suppliers) as by a firm need. And whether they would accept another supplier and engine type, unproven in local conditions, is debatable. Still, WAGR later convinced itself that an Alco-engined Cape gauge locomotive would be a “good idea” and had Comeng build such for it. But the Alco engine was already well-known in Australia.

The larger locomotive, a 174 ton Co-Co unit, had a 3750 hp Sulzer 16LVA24 engine. It appears to have been aimed at the Pilbara AAR-sized iron ore roads, with most likely the chances of an actual sale were in the slim-to-none range.

At the time Brush (represented in Australia by Hawker Siddeley) indicated that it was prepared to partner with any suitable Australian builder. The same basic locomotive ideas was recycled in a short item in RT 1966 November, by which time Tulloch had been established as the Australian Brush licensee.

An interesting facet of the Sulzer LVA24 locomotive engine is that in 1966, following the absorption of Ruston & Hornsby, with the cohort from latter apparently then dominating policy, English Electric (EE) had planned on building that Sulzer engine to replace its own RK. As part of this arrangement, it developed and type-tested a cast crankcase version of the LVA24. For reasons that remain unknown, this arrangement did not sustain, and EE went back to its RK, developing the Mk III version. Brush did use the latter for the BR Class 56.

(Courtesy Steve Palmano)

![]()

USA - proposed locomotives using the Sulzer LVA range.

With reference to the Southern Pacific (SP) diesel-hydraulic experiment, the SP had asked Kraus-Maffei to quote also on designs with other than the Maybach engines. One such was based upon a pair of GE 7FDL-12 engines, but the locomotive was too long for the SP. (Alco might have had to do a little crowding on the DH643 to meet the length limit.) Another option involved a single Sulzer V16 engine. This was surely the 16LVA24, and suggests that it might have been offered at 4,000 hp in the early 1960s. It drove two hydraulic transmissions. That meant that the engine was capable of delivering full torque from both ends, something unusual, but not impossible with care and attention to torsional vibration possibilities. Whether that applied to the 16LAV24 generally, or whether a special version was envisaged for the diesel-hydraulic case is unknown. Evidently, despite its reservations about the Maybach engine, SP saw a new and untried engine combined with a new and untried two-transmission technique was too much of a risk.

(Courtesy Steve Palmano)

![]()

Previously it had been stated: On balance I think it would be difficult to draw a robust conclusion that the failure of the LVA24 engine to gain a material share of the market was attributable to EE’s involvement, or that EE obtained the licence simply in order to obtain some technology that it could then apply to its RK series. Rather the joint effort was potentially mutually beneficial; the apparent problem was that few potential customers were interested in a new engine. I suspect that even had enough business been found to continue the project, EE still would have found it necessary to continue – and update – the RK series in order to meet the needs of existing customers who did not want a change of engine type. Had Sulzer nonetheless continued to offer the LVA24 engine without EE’s involvement, then although it was not in the frame for the BR class 50, it might have been a candidate for later projects such as the class 56, bearing in mind that the concerns that had arisen with the class 48 installation had been resolved. But that would almost certainly have required that the engines be built under licence in the UK. Whether Vickers, who had built the LDA28 series. would still have been a candidate I do not know. I imagine that it could well have seen the EE collaboration as signalling the end of its tenancy.

As mentioned, the Jane’s 1969-70 diesel engines listings included the EE-Sulzer LVA24 under English Electric (UK) and the Sulzer LVA24 under CCM Sulzer (France). There was also an engine listing for Sulzer (UK), which covered the LDA28, as built by Vickers Ltd, but not the LVA24. One may wonder why Vickers was not a participant in the LVA24. Possibly Sulzer was intent on having a cast crankcase, which Vickers might not have been equipped to do. On the other hand, EE had an established foundry that was generally viewed as a first-class operation.

There is evidence that EE did include the LVA24 engine in some of its projected locomotive designs. This is mentioned in the book by Brian Webb, The Deltic Locomotives of British Rail” in chapter 10, “Deltic Possibilities”, thus:

Moving on to the 1965-67 period and the so-called 'Super Deltic' which was in fact produced in three designs (along with alternatives with up-rated EE conventional engines, EE-Sulzer engines, and the French AGO engine), the Deltic-engined locomotives all had two 18-cylinder engines each rated at 2,000hp in two designs, and at 2,300hp in a third, giving in this case 4,600hp for a service weight of 114 tons - less than the Class 47! All three were similar to the coming Class 50 2,700hp EE locomotives for BR so far as the mechanical design was concerned, the two 4,000hp versions weighing 117 tons and all three being of Co-Co layout. BR considered costs for batches of twenty and fifty.

Thus EE was offering the customer a choice of engines, both in-house and third party (SACM). Presumably it had done the basic engineering for all options, including generator/alternator choices.

As an aside, the SACM AGO option is interesting. SNCF had used the AGO230 as an alternative to the Sulzer 12LVA24 in its A1A-A1A 68000 locomotive series. The AGO195 and AGO230 (later AGO240) engines were derived from the SACM MGO high-speed engine, although they were not simple extrapolations. The AGO195 was also definitely a high-speed engine, whereas the AGO230 fell somewhere between medium-speed and high-speed. SNCF had characterized it as 'semi-rapid' as compared with 'rapid' for the MGO. But reflecting its origins, it was certainly lighter than typical medium-speed engines of similar output. That may have made it attractive as an alternative to both the RK and the LVA24 for the possible BR need.

Regarding Sulzer’s discontinuation of the LVA24 programme, this was mentioned in a 1982 IME paper (1) about the development of the A25/30 engine. To quote therefrom:

'In short, the engine [the A25/30] was to be suitable for 'universal' application, first auxiliary power generation, next marine propulsion and, finally, traction. Development of the LVA24, a 'pure traction' engine - was stopped in the early part of 1970 and the first traction application of the A25 engine entered service in 1978.'

Given that both EE and Sulzer (France) listed the LVA24 engine in Jane’s 1969-70, it looks as if both discontinued it at the same time, which suggests that it was a mutual decision. Evidently Sulzer had realized before then that a railway-only medium-speed engine programme was not supportable, and that railway applications would need to be covered by a multipurpose engine design. From the same paper:

'DESIGN PHILOSOPHY AND INTRODUCTION TO THE A25 ENGINE

'The call for a new range of engines arose for two main reasons. Firstly a modern replacement was required for the BA22 and BA29, and its later derivative, the BCA29, as they were no longer fully equal to requirement and, secondly, with the merger of Sulzer and Swiss Locomotive and Machine Works (SLM) a rationalisation of models was necessary since the SLM VD2511 engine was also in much the same situation as the Sulzer engines mentioned above.

'It was decided therefore to develop a new engine, intended at first mainly for generating electricity in marine and stationary installations. For that reason the mean piston speed was kept conservatively at 7.5 m/s at a rated speed of 750 rev/min initially, although the design would allow for development to 1000 rev/ min, piston speed 10.0 m/s. Based on a test engine and on the high b.m.e.p. of the LVA24 locomotive engine, the nominal b.m.e.p. was fixed initially at just below 15 bar. With ultimately locomotive application implied, the bore/stroke ratio was fixed at 1:1.2, so that a 300 mm stroke gave a bore of 250 mm, with an envelope which could be accommodated within the UIC loading gauge.

'The team entrusted with the development and design of this engine was given a remit which included the following:

'Robustness with compact layout and high specific output, i.e. optimum operational reliability.

Good access to all major components, especially those subject to wear and tear.

Economy in production and operation.'

And:

'The engine forming the subject of this paper emerged in its basic form in 1967. It took many features from the LVA24, an engine designed specifically for traction - probably the last such engine to be designed for such a limited application.'

Some sources suggest that development of the A25/30 started even earlier than 1967. Be that as it may, it is apparent that the future pathway had been mapped out before what EE did or did not do could have had much influence on what happened. Possibly the work with EE was part of a final effort to save or at least extend the LVA24 programme.

As it happened the A25/30 did not succeed as a rail traction engine, probably more for circumstantial than fundamental mechanical reasons or insuperable problems. The USA experiment was anyway in the nature of a “mission impossible” task. And the engine itself was discontinued after Sulzer was absorbed by Wärtsilä in 1997. Wärtsilä already had that market slot covered with its W26 model, new in 1995. The 'competing' SACM AGO seems to have come to a similar end. SACM became part of Wärtsilä in 1989, who obtained full ownership in 1993. It was viewed as the high-speed engine arm of Wärtsilä, and developed a pair of new high speed engines, both ill-fated, probably more for marketing than technical reasons. The first, the W200 in 1995, presumably replaced the AGO195 and AGO240 models, and the second, the W170 in 1997 (actually built by Cummins Daventry, UK) presumably replaced the MGO. I cannot trace that either were suggested as rail traction powerplants by Wärtsilä itself. In the Cummins case. I do not know if the current QSK rail traction range is a derivative of the W170 design, or has different origins. Anyway, it looks as if Wärtsilä had opted out of this niche, instead focussing on marine and power generation applications. It had previously dabbled in rail traction applications for its VASA 22 medium-speed engine, but apparently unsuccessfully so. Its VASA 22 programme was described in an SAE paper (2).

As already mentioned, the Sulzer A25/30 was effectively replaced by the W26, which might have been a rail traction candidate had Wärtsilä been interested in that market segment. In fact c.2000 Wartsila did develop a lighter, higher performance version, the 26X, for the marine fast ferry market, and this might have been a better starting point for the medium speed rail traction market. But that variant seems to have sunk without trace. Connecting some more dots, by then the fast ferry market was primary for the Ruston RK270, which had thus moved from its design origins as a locomotive powerplant. And its success there inspired the development of the RK280 (later MAN V28/33D) aimed precisely at that market. In fact, I don’t think that the RK270 had any locomotive applications beyond experimental. Perhaps Sulzer was prescient in the later 1960s in recognizing that a locomotive-only medium-speed engine programme was no longer viable, at least for an independent engine builder as distinct from an integrated locomotive builder. And maybe Wärtsilä missed an opportunity when it cancelled its W170/W200 programme; not too far in the future the high-speed engine was to play a much larger role in locomotive applications in the world outside of North America. With 20/20 hindsight, one could ask whether during the 1960s, EE might have been better off not investing in the LVA24 engine, but rather putting its money into completion rather than cancelling its high-speed U-engine programme. The 1500 rev/min U was of similar dimensions to, but more robust than the Paxman Valenta. Still, as late as 1982, high-speed engine specialist MTU still viewed its potential locomotive market as being a small niche, for example low axle loading applications where the established American designs with medium speed engines were not good fits. So the future swing to high-speed engines was then still below the horizon.

(1) IME C95/82, 'Rugged simplicity or technical complexity', by A.T.H. Tayler, Sulzer Bros (UK) Ltd.

(2) SAE 871371, 'Presentation of Wärtsilä Diesel Rail Traction Engine Technology and Program', Alf Skatar, Wärtsilä Diesel.

Courtesy Steve Palmano.

![]()

In looking back at the Sulzer LVA24 episode, one could say that it was a bold move by Sulzer to design and develop a new medium-speed engine solely for locomotive applications, particularly when it was not a locomotive builder and so did not have a 'captive' market. One may invoke a couple of reasons, though. The first one is essentially inertial, in that Sulzer had historically kept its locomotive engine range separate from its marine and powergen range, although the former did find some non-locomotive applications. Secondly its existing LD range of locomotive engines was by the mid-1950s looking somewhat out-of-date. In particular, its double bank approach for the largest engines was not aligned with prevailing practice, which favoured vee engines. The fact that two crankshafts were required would have incurred a relative cost penalty. In the 1960s, the 12LDA28 price (presumably, UK-built, to BR) was said to be £45k, as compared with £26k for the EE 16CSVT. Effectively, a new vee-engine was the only option if Sulzer was to stay competitive in both technical and economic terms.

Nonetheless, I suspect that the LVA24 was simply the first manifestation (driven by its relative urgency) of a major move by Sulzer to renew the whole of its trunk piston engine range, the marine/powergen side of which was also looking somewhat long in the tooth. Certainly, its 1955-onwards test programme in which inter alia it compared two-stroke and four-stroke designs looks to have been as much for the marine/powergen case as for the locomotive case. The UV32 vee-four test engines used in that programme had a 320 mm bore, which was certainly a marine/powergen size, not a locomotive size.

In that light, the fact that the A25/30 engine was based upon the LVA24 design was probably no accident, but part of the overall plan, in which a basic, smaller four-stroke design would be optimized along separate vectors for the locomotive and marine/powergen cases, with the former being done first. That the detail design of the A25/30 allowed for eventual locomotive use suggests that by c.1967, Sulzer may have seen the LVA24 programme as not necessarily being sustainable in the longer term. The combined LVA24 and A25 programme was probably profitable for Sulzer, even if the LVA24 part taken in isolation was not. (The other output of the 1955 programme was the Z-series of larger bore marine/powergen engines, which followed the LVA24 and preceded the A25; this was very successful.)

It was probably more happenstance that the 250 x 300 mm bore and stroke dimensions of the A25 were very close to the 254 x 305 mm of the EE RK engine. Equally one could also point to the successful Nohab F marine/powergen engine as a good 250 x 300 mm precedent.

This diagram shows the similarities (and differences) of the LVA24 and A25/30 engines:

Courtesy Steve Palmano.

![]()

The available data on the LVA24 engine shows that as standard, Sulzer used its own locomotive-type governor. This continued a pattern that had been established back in the 1930s. I imagine that originally this was done so that speed control, load control and other features could be incorporated within the governor at a time when the proprietary offerings did not allow for this. On the other hand, for its marine/powergen engines, including the large two-stroke crosshead types, Sulzer typically used Woodward governors. As far as I know, Woodward did not offer internal speed and load control for locomotive applications until its 'New SI' model of 1945, by which time Sulzer was probably well-committed to its own pathway for the locomotive case.

Apparently standard for the LVA24 was continuously variable air pressure engine speed control. But Sulzer had developed an alternative version of its governor with a stepped eight-speed control using three solenoids for the 6LDA28C engines of the Nigerian 1401 class. Possibly this was used on the AT25/30 engines in the 'American experiment'. But a suitably configured Woodward PG model would also have been a contender, with the benefit that it was a standard item in US practice.

One may only guess at what governor would have been fitted to an EE-built LVA24. EE had its own governor with external speed and load control assemblies, but from c.1962 also fitted a customized version of the Woodward PG when customers so wanted. Then the Regulateurs 1100 came into the picture, and appeared to be standard for the RK Mk III, although in practice seldom used in locomotive applications. (The Ardleigh 302/303, predecessor to the Regulateurs 1100, had been used on the Napier Deltic engines.)

Sulzer also viewed the LVA24 engine as being a candidate for use in diesel-hydraulic locomotives.

Courtesy Steve Palmano.

![]()

Sulzer Engines and Hydraulic Transmission

As mentioned in this posting - https://groups.io/g/World-Diesel-Loco/message/13464 - Sulzer saw its LVA24 engine as being suitable for diesel-hydraulic as well as diesel-electric locomotive applications.

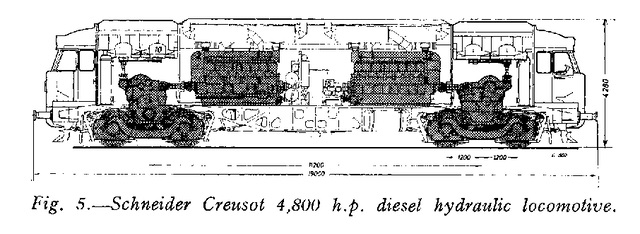

Here is a sketch, from 1966, of a 4,000 ps, 83 tonne, B-B diesel-hydraulic proposal using a single 16LVA24 engine, but with two hydraulic transmissions:

Although in outline the locomotive had a 'Swiss' look, I suspect that it was aimed primarily at SNCF. It could be seen as a single-engined version of the SNCF BB69000 prototype pair of 1964:

This weighed 84 tonnes, and although shown as being of 4,800 hp, other sources suggest that it was actually of 3,500 hp.

Like the BB69000, it had its hydraulic transmissions mounted transversely on monomoteur bogies. The transmission type was not shown on the sketch, but a Voith size eight triple converter seems likely. The BB69000 had Voith L821 two converter, one coupling units. This arrangement was analogous to the monomoteur bogies, with large centrally mounted single traction motors used in French electric and diesel-electric locomotive practice.

Nonetheless, the SNCF did not appear to be much interested in diesel-hydraulic line service locomotives, preferring the diesel-electric type. Though there was some French interest in mechanical transmissions for line-service diesels, with small-scale work carrying on into the 1960s.

Clearly the 16LVA24 engine was, or could be configured to deliver at least half-power from both ends. That facility was probably unusual, although not unknown, in the 1960s, although I understand that it is a reasonably common feature of more recent medium-speed engines.

Sulzer’s idea of using one engine with two hydraulic transmissions goes back somewhat, this diagram being from a 1959 paper:

It actually refers to the 2500 hp 12LDA28B double-bank engine. How that might be configured to drive two transmissions is an interesting question. But in context, the main point was to show that the hydraulic transmission curve was inferior to that of electric transmission. A similar, but generic curve was shown in a 1961 paper.

The fact that in both cases, Sulzer showed a smooth propellor (cubic) curve for the hydraulic transmission case suggests that it preferred the all-converter type over the converter-coupling combination, the curve for which would have a discontinuity at the changeover point. That is why I think that a Voith triple converter transmission (or perhaps one of the later wide-range two-converter types by then emerging) for its 1966 proposal. It could be too that the highly turbocharged LVA24 did not take to well to running on the torque curve as would be the case in the coupling phase. A pertinent comment was made by in a 1967 paper by R. Keller of Voith: 'Unfortunately, most engine manufacturers severely restrict the operating speed range of the diesel engine at maximum torque so that the use of the hydraulic coupling has again become retrogressive.'

Apart from the 1966 case above, there was an earlier proposal for a single-engine, two-transmission locomotive. In its 1962 tender for 'production' diesel-hydraulic locomotives, the Southern Pacific (SP) had asked Krauss-Maffei (KM) to quote on alternative designs that did not use the Maybach MD970 engine. Accordingly it offered one that was said to be powered by a single Sulzer V16 engine. Logically this would have been the 16LVA24. But SP wanted a production locomotive, not another prototype, so it stayed with the MD870 engine for its batch of 15. Apparently SP had also asked KM to quote on a locomotive powered by two GE 7FDL12 engines, which it did, but the resultant design was too long for the SP. Later of course, the SP was one of the American roads involved in the AT25/30 experiment.

It may be noted that there was a previous association of a Sulzer engine (in this case the 6LDA25) with hydraulic transmission (Voith triple converter type). This was in a 1954 group of eight locomotives for French Outre Mer service.

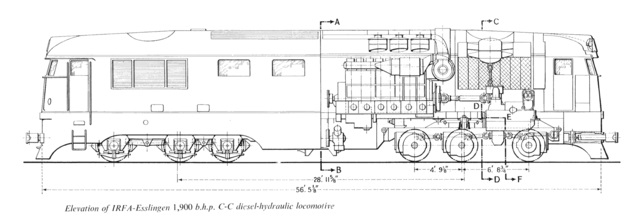

Also, the bogie-mounted hydraulic transmission was not a new idea. It had been used by Esslingen for a batch of 23 metre gauge C-C diesel-hydraulic locomotives supplied to Brasil in 1953-54, 10 for VF Rio Grande do Sul and 13 for EF Leopoldina. In this case it could have been that bogie mounting of the transmissions was the easiest way to drive all three axles of each bogie without any “double-decking" of the transmission output shafts.

Courtesy Steve Palmano.

![]()

Resources and other reading materials

Personal recollections from Christopher Brooks & Geoff McEwen.

From the Mountains to the Sea - The Sulzer Diesel Engine; JA Somer & DT Brown 1998

Traction Magazine: October & November 1998.

Retrospective from Steve Palmano.

Sulzer LVA24 publicity brochure.

Page added November 14th 2008.

Last updated August 17th 2023.