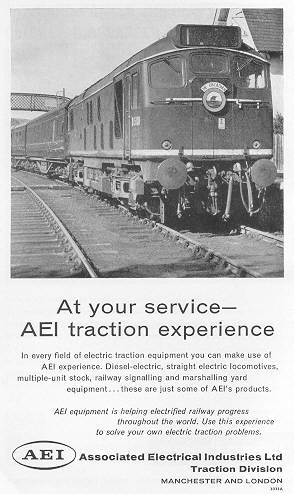

BR/Sulzer Type 2 D5130 features in a 1962 advertisement for AEI Traction Division. The Type 2s did not have the honour of hauling many named trains, but 'The Orcadian' was very much their province, being introduced in 1962 as a fast four hour service to Wick/Thurso, departing Inverness at 9.05am.

In 1928 Associated Electrical Industries (AEI) was established as a result of the merger of rivals Metropolitan-Vickers (MV) and British Thomson-Houston (BTH). This combination would be one of the few companies with the ability to compete with Marconi's Wireless Telegraph Company or the English Electric Company. Also included in the new group were Edison Swan Electric Company (Ediswan) and Ferguson Pailin of Openshaw, Manchester (which BTH had been in the process of buying in 1928). MV & BTH remained separately quoted companies, were frequently in competition with each other, with poor communication across the companies and intense rivalry, which amongst other things prevented AEI from gaining effective control.

By 1956 the main companies in the AEI Group were: BTH, Metropolitan-Vickers Electrical Co, Edison Swan Electric Co, Ferguson Pailin, AEI Lamp and Lighting Co, Hotpoint Electric Appliance Co, Coldrator, Newton Victor, Premier Electric Heaters, Siemens Brothers and Co, Sunvic Controls & AEI-Birlec.

During 1957 & 1958 reorganisation commenced to assimilate the three subsidiary companies into one, with all to use the AEI brand name, whilst separate trading of the constituent companies would cease. On January 1st 1960 AEI stopped using the names BTH and Metrovick. The three main manufacturing companies were reorganised into divisions of AEI: Turbine-Generator, Transformer, Traction, Switchgear, Instrumentation, Electronic Apparatus, Heavy Electrical Plant, Motor and Control Gear, Cables, Construction (Cables and Lines) Radio and Electronic Components & Telecommunications. What was planned on paper suffered badly in reality, sales fell in the heavy electrical industry because the brand name 'AEI' was unknown, leading to a serious drop in AEI's stock price. The two separate management structures were never successfully combined, by the mid-1960s the entire AEI empire was in financial trouble.

In 1959 AEI came to an arrangement with Alco, who built both diesel engines and the mechanical parts of locomotives, and was an established manufacturer with a worldwide market base. Added to that was the established access to GE technology on the BTH side of AEI, which meant that AEI could supply equipment that was interchangeable with that which GE supplied to Alco.

By 1961 AEI was Britain's largest electrical manufacturer which included design, manufacture and distribution; the company had 103,450 employees with Works in more than fifty UK towns.

Perhaps the greatest opportunity for AEI with regard to a large locomotive order came in 1961 with the consortium of BRCW/Sulzer/AEI producing a six axle 2,750hp 114 ton (gross) demonstrator as the next step in British Railways Type 4 development. As dealt with elsewhere in this website this proved to be a dead end for BRCW & AEI.

Throughout the life of AEI the company struggled with the internal rivalries between BTH & MV, though the subsidiaries themselves were very successful especially in the War years (1939 - 1945), the parent never resolved the serious problem of integration. The drastic revitalisation and leadership required to enact this major change was not forthcoming and the whole issue faded into oblivion when GEC made a GBP120 million bid for AEI, with the merger taking effect on Thursday, November 9th, 1967.

Interestingly less than a year later on September 6th, 1968, GEC also acquired The English Electric Company, at a stroke, literally, a multitude of competing electrical suppliers at the onset of British Railways Modernisation Plan were now consolidated into one major company.

Rolling stock on British Railways that utilized AEI electrical equipment (this list is not exhaustive):

Ruston & Hornsby 0-6-0 shunter, Class 07: 2985 - 2998, one traction motor.

BR/Sulzer Type 2s, Class 25: 5176-5299, 7500-7677 (25026-25327), four AEI 253 AY traction motors.

BRCW/Sulzer/AEI Type 4, D0260 'Lion', (introduced 1962), six AEI traction motors.

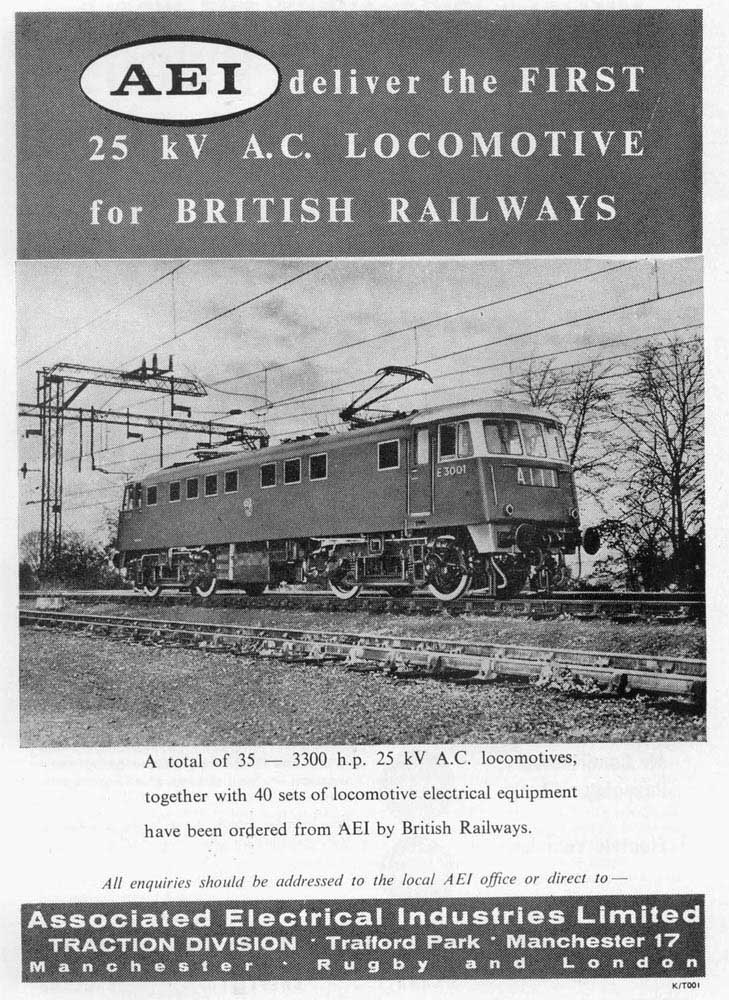

AEI/BTH BoBo Type A Electric, Class 81: E3001-E3023, E3096/97 (81001-81023), four type 189 847 hp d.c. traction motors.

AEI/MV BoBo Type A Electric, Class 82: E3046-E3055 (82001-82008), four type 189 847 hp d.c. traction motors.

BR/AEI BoBo Type A Electric, Class 85: E3056-E3095 (85001-85040), four type 189 847 hp d.c. traction motors.

Class 304 four car emu LMR 001-045, four AEI 207hp dc traction motors, introduced 1960.

Class 303 four car emu ScR 001-091, four AEI 207hp dc traction motors, introduced 1960.

Class 311 four car emu ScR 092-110, four AEI 222hp dc traction motors, introduced 1967. Possibly the last powered rolling stock on BR to have electrical equipment using the AEI brand.

Addendum No.1

Response from Steve Palmano with regard to the AEI 253 traction motors.

As I understand it, the problems with the AEI 253 motors on the BR Class 25 class were not by and large intrinsic to the motor itself, but the result of incorrectly set control systems, particularly in respect of field diversion. The effects were worse when two locomotives with widely different settings were operating in MU. The use of road-speed controlled field diversion on late class 25 production was an improvement. I think this had been part of the GE lexicon for some time. AEI may have taken a while to get to grips with the different nature of the 253 as compared with its traditional motors.

Brian Webb summed up the situation thus: “The outcome was that it was considered to be variations in equipment, notably the field divert relays, and their poor adjustment which caused this problem. Other factors included variations in traction motor cooling due to blowers being faulty or incorrectly maintained, diesel engines putting out to high bhp due to governor changing, load regulator switches failing in closed position and causing current fluctuations, and excessive motor current.”

That is not to say that operation of the AEI 253 motor in continuous high-speed service would not have thrown up problems, but it is difficult to imagine that these could not have been solved. The prototype GE 761 motor was subject to ongoing improvements over the years, and was eventually capable of handling around 700 hp. All of this was presumably transferable to the AEI 253. Of course, in an environment where maintenance was indifferent or even poor, which does seem to have been the case for BR, then any kind of reasonably advanced technology was at risk. Perhaps the AEI 165 motor, counterpart to the GE 752 standard gauge unit, would have been less susceptible to problems, but then the track would have suffered more from its higher unsprung mass in an axle-hung installation.

Thus I’d say that AEI had made a forward-looking decision in choosing the 253 motor for the Lion. It anticipated that in the lifetime of such a locomotive, track speeds would need to rise, perhaps up to something like 110 mile/h for locomotives with axle-hung motors, and therefore that reducing unsprung mass was highly desirable, if not essential. That was a vector that might have forced the further development of lightweight motor design with concomitant traversing of a learning curve, but that would have led to a better result than falling back upon the “safe” option of a heavyweight motor.

Of course, BR had made the quest for higher power and speed with a 19-ton axle loading unnecessarily difficult by its insistence upon the very heavy Sulzer 12LDA28 engine, which turned out to be a real problem child, and an expensive one as well. Tufnell gave the price of the Sulzer engine as £45k as compared with £26k for the English Electric 16CSVT; this would have been in the early 1960s. Weights were given as 22.3 tons for the 12LDA28 and 19.4 tons for the 16CSVT. The heavy engine meant that all other parts of the locomotive had to be as light as possible, in some cases more so than good engineering judgement might have otherwise indicated. The Lion came in at the specified maximum of 114 tons. The first batch of class 47s were overweight at 117 tons, but it appears that if Brush had been admonished for that transgression, it got off by promising to do better in the future. Deletion of the electric train heating facility, a majorly retrograde move, seems to have been part of “doing better”.

![]()

The US based American Electric Company sold their products to the English market through the The Laing, Wharton & Down Company, the latter formed in 1886 and incorporating in 1889. The American Electric Company was later renamed the Thomson-Houston Company and in 1892 became the General Electric Company (USA) following the merger of the Thomson-Houston Company and Edison General Electric. Two years later in 1894 the Laing, Wharton and Down Construction Syndicate was renamed British Thomson-Houston (BTH) having acquired the British rights to the Thomson-Houston patents, with BTH being majority owned by General Electric Company (USA). Over time BTH became well known for steam turbines and electrical systems.

The Power Act of 1900, which would bring electricity supplies to large areas of the country included BTH as one of the suppliers. Rugby was selected as a production center, aided by nearby coal supplies and good railway connections, land was purchased in 1900 with manufacturing commencing in March 1902, principally steam turbines, motors, converters & switchgear.

The advancement of electrified underground and commuter railway routes in the United Kingdom saw BTH win contracts in 1903 from the North Eastern Railway to provide electrical equipment for motor units, carriages and laying of third rail and the District Line's use of the Sprague-Thomson-Houston system of multiple unit train control. In 1904 BTH became the contractors for the Central London and Great Northern and City lines electrification using direct current.

1909 saw BTH provide electrical equipment for London's first trolley buses. Equally important was the production of lightbulbs, made possible by the growth of the electricity grid. Expansion because of World War One and afterwards saw factories established at Birmingham, Chesterfield, Coventry, Lutterworth & Willesden, with production now featuring domestic appliances.

The diversity of BTH was illustrated in 1922 when it became one of six telecommunications companies to found the British Broadcasting Company (BBC).

The various BTH works specialised in items produced: Rugby - turbo plant, heavy machinery, electric traction equipment and lighting and radio material; Birmingham - electric motors; Coventry - radio apparatus and fractional horse-power motors and Willesden - switch gear.

A proposed merger of a number of electrical companies in 1926, headed by GEC of America, came to nothing. However in 1928 BTH merged with Metropolitan Vickers, also included were the companies Edison Swan Electric Company (Ediswan) and Ferguson Pailin of Openshaw, Manchester (which BTH had been in the process of buying). The merger included the acquisition of the Ordinairy shares in BTH held by General Electric of USA. In 1929 the merged entities became known as Associated Electrical Industries (AEI). Although MV & BTH were now under the same roof with very similar product lines they kept their identities & operations separate, which would eventually lead to serious commercial rivalry between them, causing a serious internal destabilising influence for AEI.

The Depression years hit the company hard, but AEI continued to expand its (BTH) Rugby plant. During 1935/1936 the Rugby plant was involved with Frank Whittle in constructing one of the world's first jet engines. BTH appeared disinterested in the development of the jet engine, in 1943 Rolls Royce took over the production.

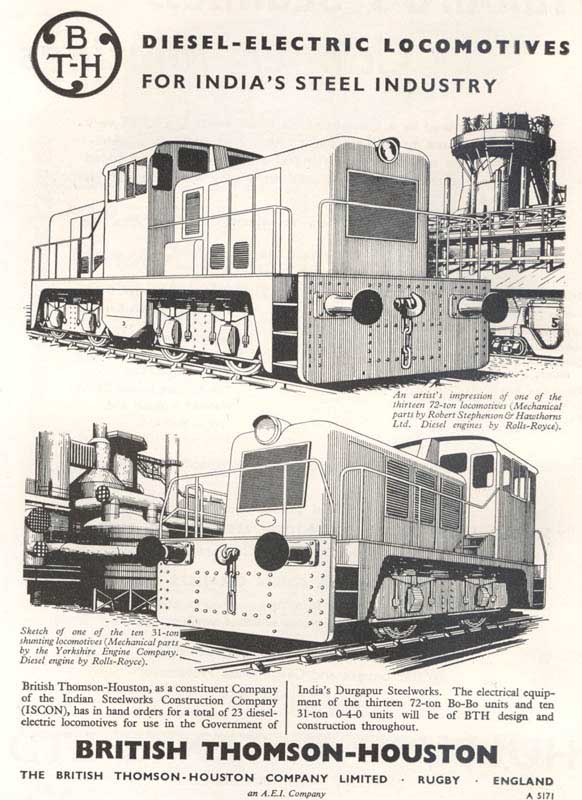

In 1950 the LMS/Ivatt originated branch line prototype diesel electic locomotive 10800 was built using the consortium of NBL/Paxman/BTH. Surprisingly NBL had already established a relationship with GEC to supply NBL-GEC diesel-electric and electric locomotives.

During 1950 BTH received two export orders. One was from NSWGR for ten of its twin-engined 41 class, and the other from WAGR for 18 of its Y class. Both were shunting/transfer locomotives, but suitable for some line service. Both used Paxman high-speed engines. For the NSWGR 41, BTH worked with Metro-Cammell as mechanical parts supplier, whereas for the WAGR Y, it worked with Clayton. The 41 was close to being a failure, inadequate design leading to serious problems with engine cooling. The Y fared a bit better, though later events revealed serious inadequacies with the Clayton company.

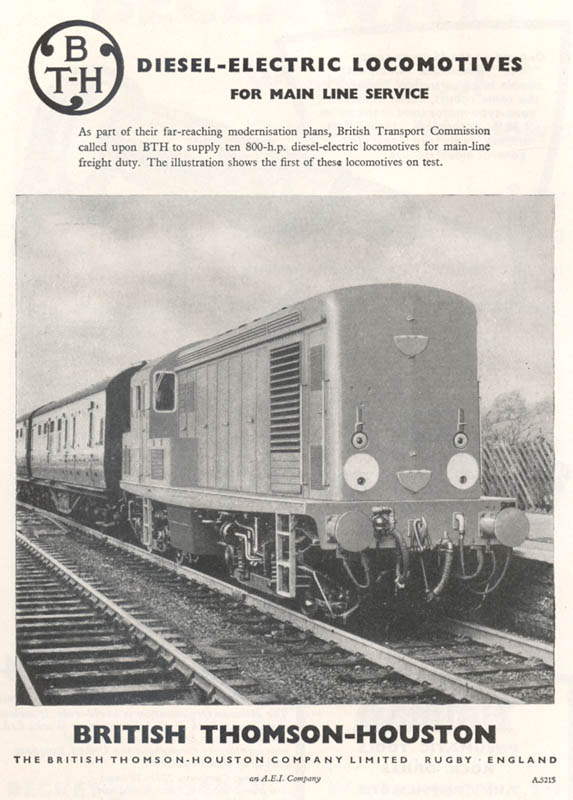

The BTH/Paxman combination reappeared in a British Railways Modernisation Plan order, the 82xx series (later Class 15), with Clayton handling the mechanical parts. This was somewhat successful as a second order was recieved. However of far greater impact for BTH was its selection as the electrical equipment supplier for the BR-built, Sulzer-engined 5xxx series (later Class 24/25) from the Modernisation Plan, a production run which produced 176 locomotives. A further 302 would be built, but using AEI branded equipment. Thus BTH was now involved with true line-service locomotives.

The successes for other parts of BTH organisation continued into the 1950s, with BTH constructing Europe's largest turbine works, at Larne in 1957.

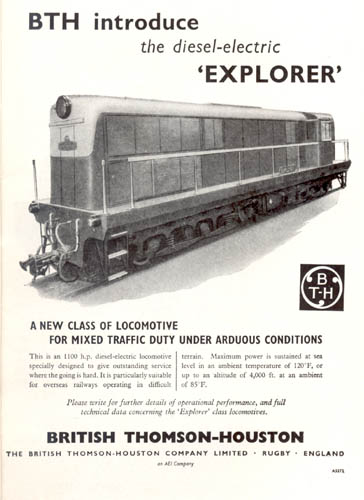

Looking at the export market in the late 1950s BTH, with Clayton and Lister-Blackstone commissioned the Explorer CM-gauge prototype, which was ready in 1959. This featured a Lister-Blackstone engine, BTH electrical equipment and mechanical parts by established partner Clayton. Possibly Lister-Blackstone saw this as a pathway into the mainline locomotive market, as the cost was shared between itself and BTH.

At 1100 hp (gross), with Co-Co running gear and weighing 72 long tons, the Explorer may be compared with standard road switchers from the major worldwide builders. Previous engine partner Paxman offered high-speed engines which were in a lower power range than needed for the Explorer. The Alco DL531 was slightly lighter (in CM-gauge form) and marginally less powerful, at 975 hp (gross). The GE U9C was somewhat heavier and had a nominal power of 990 hp (gross), but this was a high-altitude, high-ambient temperature rating, and the UIC number was 1060 hp. The Alco & GE utilised 6-cylinder in-line engines, whereas the Lister-Blackstone featured the relatively complex 12-cylinder double-bank form, albeit still medium-speed. This complexity allied to its weight put it at an immediate major disadvantage. There were no production orders from this prototype.

In 1959 EMD did not yet have a six-motor model in this power class. English Electric no doubt could have offered a Co-Co version of its existing eight-cylinder Latin American model with either the 8SRKT or 8SVT engine, by 1959 delivering 1100 hp. And more power would have been available from the 8CSRKT or 8CSVT engine with but minor weight penalty. Within two years Alco offered the DL535, delivering 1350 hp (gross), still with six cylinders, and weighing around 72 long tons in CM-gauge form.

The Explorer was built by the Clayton Company of Hatton, Derbyshire, order number 3548 of January 1959, it was powered by a Lister Blackstone ERS.12T 12 cylinder twin-bank engine powering BTH electrics. Cylinders were 8.75 x 11.5 inches, maximum crankshaft speed was 800rpm, output speed through the phasing gears was 1,320rpm providing 1,100hp. Either crankshaft could be uncoupled in an emergency.

The locomotive weighed 72tons and rode on metre gauge Co-Co bogies of rubber cone pivot Alsthom style. Alsthom (originally ALS-Thom(son)) had a similar relationship with GE as did BTH, and it appeared that design ideas also travelled 'horizontally' between GE 'associates'. This aspect of the Explorer design was carried over to the later AEI Zambesi type.

It was leased to the East African Railways who later bought it outright. In the late 1960s EAR reclassification it was assigned Class 79. It was allotted to the Kenya Railways in 1977, though by October of that year it was recorded as 'stabled for scrap' on the roster. As of 2005 the 'Explorer' locomotive still existed, very much intact and still bearing its number and nameplates. It was earmarked for the Nairobi Railway Museum when funding become available. The locomotive was retired to the sidings of the Training Centre in Nairobi with an expectation that it would be transferred to museum stock. Unfortunately, as late as May 2011, it was purchased from Kenya Railways and scrapped in situ.

A late 1950s BTH contract was with NZR for 18 Dsc class shunting and light line-service locomotives. Rolls Royce was the engine supplier. Clayton built the mechanical parts, and apparently made a very poor job of what was basically a good design. NZR was not impressed by Clayton’s lack of capability, and when it wanted more of the same locomotives, it built them itself.

AEI's internal reorganisations and the continuing rivalry between BTH and Metropolitan Vickers presented management with a considerable challenge. One aspect of unification was to promote the AEI brand name in place of the BTH & MV names, a move which backfired on AEI because the brand name of AEI was unknown, leading to falling sales, further impacting profitability. The BTH brand name was discontinued effective January 1st 1960 - see AEI above.

Continued attempts to bring together the two divisions together did not meet with the greatest of success, however all would be of no consequence when GEC successfully bid for AEI in 1967. At the time the 'AEI' brands included Metropolitan-Vickers, BTH, Edison Swan and Ediswan, Siemens Brothers, Hotpoint, Birlec and W. T. Henley. With this acquisition GEC became the United Kingdom's largest electrical group.

During the 1980s the facilities at Rugby were downsized with many building being torn down and the land reused for new development.

Rolling stock on British Railways that utilized BTH electrical equipment (this list is not exhaustive):

BTH/MV/WH Allen 3 diesel electric shunters (introduced 1931) for Ford Motor Company, Dagenham, four BTH 26hp traction motors.

BR/NBL/Paxman Bo-Bo 10800 (introduced 1950), four BTH traction motors.

BR 0-6-0 shunter, 'Class 08': 3152-3166 (all withdrawn by late 1967), two BTH traction motors.

BR/Sulzer Type 2 Class 24/25: 5000 - 5175 (24001-24150, 25001-25025), four BTH 213hp traction motors.

BTH/Paxman Type 1 Bo-Bo: 8200 - 8243 (introduced 1957), four BTH traction motors.

Ruston & Hornsby 0-6-0 shunter: PWM650 - PWM654, one BTH traction motor.

Brush BoBo electric ES1 class (introduced 1902): 26500 & 26501, four BTH traction motors.

Battery Electric LMS shunter (introduced 1917): Bel 2, two BTH traction motors.

LMR Wirral/Mersey emu Class 503 (introduced 1956): M28371M-M28394M, four BTH 135hp traction motors.

LMR Wirral/Mersey emu Class 503 (introduced 1938): M28672M-M28690M, four BTH 135hp traction motors.

SR 6-PUL emu: 3001-3020, 3041-3043: eight BTH 225hp traction motors.

SR 5-BEL emu: 3051-3053, four BTH 225hp traction motors.

![]()

Metropolitan-Vickers Electrical Company (MV) grew out of the American owned firm of British Westinghouse. The company was formed in 1899 and was located at Trafford Park, Manchester, being well known for their industrial electrical equipment & generators, steam turbines and diesel locomotives. During World War One it was felt that American ownership of the company had been a hindrance to gaining government contracts, a British holding company was established in 1916 to acquire the American shares, with finance provided through the Metropolitan Carriage, Wagon & Finance Company and Vickers. By 1918 British Westinghouse Electrical & Manufacturing was finally under British control, continuing under the same name until requested by American Westinghouse to discontinue the use of 'Westinghouse' in the company name. The acquisition by Vickers in 1919 of Metropolitan Carriage, Wagon & Finance Company included 99% of the share capital, changing the name to the short-lived Vickers Electrical Company Ltd and then to the more familiar Metropolitan-Vickers Electrical Company (MV) in September 1919.

The diversity of MV was illustrated in 1922 when it became one of six telecommunications companies to found the British Broadcasting Company (BBC).

During 1926 a new company, Metropolitan-Vickers-GRS Limited, was formed jointly with the General Railway Signal Company of Rochester, New York, to sell railway signalling equipment, under the design of the American company, but made at the Trafford Park works.

Many problems faced British industry in the 1920s; low investment, political & labour unrest, import & export restrictions, all factors with many others culminating in the General Strike in 1926. Despite these ongoing issues MV expanded their markets both at home and overseas. The Electricity Supply Act of 1926 and the formation of the electricity 'grid' produced many orders for heavy plant - turbines, generators, switchgear and industrial motors.

Vickers had anticipated amalgamations within the electrical manufacturing industry, these had not materialised, thus when a cash offer was received in 1928 by the International General Electric Company to purchase a controlling interest in the company, Vickers took the offer. However they did retain a considerable number of Ordinairy shares.

Overseas a number of offices were opened, with major successes in South Africa, Australia & New Zealand. Most unusual was its prosperous relationship established with the Bolshevik regime in Russia for the Moscow Metro development.

In 1928 MV merged with British Thomson-Houston (BTH) and on January 4th 1929 both came under the umbrella of Associated Electrical Industries (AEI). Agreement was also reached with International General Electric Co (USA) to acquire that company's shareholding in BTH. Although MV & BTH were now under the same roof with very similar product lines they kept their identities & operations separate, which would eventually lead to serious commercial rivalry between them, causing a serious internal destabilising influence for AEI.

MV survived the depression years of the early 1930s with help from overseas contracts, a major achievement in Brazil was the awarding of a contract for railway electrification, whilst a scandal in Russia led to the arrest & conviction of six of their engineers for alleged sabotage & espionage. The Russian authorities claimed that the British engineers had gained considerable knowledge about Moscow's physical layout whilst working on the Moscow Metro project. The British Government obtained the release of the engineers and resumption of trade after a short embargo.

The Second World War brought huge demands upon MV production of a wide variety of items for all the Armed Services. This included 43 (?) Avro Manchesters (the first 13 being destroyed in a Luftwaffe bombing raid on Trafford Park) and 1,080 Avro Lancasters built at facilities at Manchester Ringway and Avro's Woodford plant.

Post war production boomed, but so did the rivalry between MV & BTH, the latter opening a huge turbine works at Larne, countered by MV establishing a smaller transformer factory at Wythenshawe. As the 1950s progressed MV made a profitable name for itself in domestic appliances - refrigerators, cookers etc.

In 1949 MV formed a joint venture with Beyer, Peacock & Co, known as Metropolitan-Vickers-Beyer-Peacock to design, manufacture and assemble non-steam powered railway locomotives. A new factory was established at Bowesfield, Stockton-on-Tees.

MV worked with Sulzer on two orders, during 1950/51 they supplied equipment for the two CIE prototypes (1100/1101) and in 1956 for the CIE B class, with BRCW being the primary contractor.

In its railway applications MV appeared somewhat backward looking. The 1.5kV DC 46 Class electric locomotives supplied to NSWGR and ordered just ahead of the WAGR X class was a new design but conformed to the obsolescent 1930s articulated bogie form with a Co+Co wheel arrangement. Using more current thinking English Electric had been building large DC electric locomotives with independent swing-bolster Co-Co bogies since the late 1940s.

In 1950 MV received an order from WAGR for 48 of the X class. This was a much larger order than other British makers were getting at the time. MV worked with Crossley as engine supplier and used the joint venture with Beyer-Peacock for the mechanical parts and assembly. Although Beyer-Peacock was a competent builder, it was somewhat backward-looking in the design department, however the use of Crossley as the engine supplier proved to be less than perfect. The X class locomotive used an obsolete rigid-frame 2-Do-2 wheel arrangement, and would not have helped the way MV was perceived by potential buyers. Possibly WAGR and/or Beyer Peacock saw the X class as being essentially the diesel counterpart to its W-class 4-8-2 steam locomotives then being built by Beyer Peacock.

Then in 1954 MV took a 94-locomotive order from CIE, for 60 A class and 34 C class. In numerical terms it appeared to be doing very well. This CIE order was placed before the WAGR X class had accumulated any significant service hours, and most likely prior to the Crossley engines revealing the magnitude and intractability of their problems. For the CIE order MV did not return to Beyer-Peacock for the mechanical portion, but went with Metro-Cammell as mechanical parts supplier, a company with whom BTH had established a relationship and would feature in later MV and AEI locomotive contracts.

MV would work with the Beyer-Peacock joint venture in 1955 for the British Railways Pilot Plan order for twenty Co-Bo (later Class 28) locomotives. These were also powered by a Crossley engine, which would prove to be their Achilles heel and no doubt seriously hindered MV’s chance of success as a supplier of diesel-electric locomotives.

As part of the unsuccessful move to unify the company MV's name technically disappeared on January 1st 1960 - (see AEI above).

Rolling stock on British Railways that utilized Metropolitan Vickers electrical equipment (this list is not exhaustive):

LMR Liverpool/Southport emu Class ??? (introduced 19??): M28301 - M28310M, four MV 265hp traction motors.

Hawksworth (GWR) & MV Co-Co 18100 (introduced 1951) gas turbine, six MV traction motors (later converted to 25kV AC No.E2001.

Gresley LNER/BR & MV Bo-Bo Class EM1 1500V DC electric loco E26000 - E26057 (introduced 1941/1950), four MV 467hp traction motors.

BR & MV Co-Co Class EM2 1500V DC electric loco E27000 - E27006 (introduced 1954), six MV 415hp traction motors.

MV/Crosley Type 2 Co-Bo 5700 - 5719 (introduced 1957) five MV traction motors.

Michael Wimmer has provided the following detail with regard to the above view:

....the advertisement of MV with regard to the 135 Locomotives sold to South African Railways is of particular personal interest. The picture in the ad is an 3E. My interest is more than passing because my father, William (Bill) Wimmer was the traction engineer for Met Vick in South Africa and he was responsible at the South African end for getting the order. I well remember the day the order was announced on the front page of the Johannesburg newspaper, along with the excitement in the family and the pride we felt in Dad. The chief design engineer at Trafford Park was Frank Whyman. In 1936/7 my parents lived in Manchester (Fallowfields) as my father had come over from South Africa in order to be familiarized with all the design and manufacturing processes. My father’s work was with the Chief Electrical Engineer of South African Railways (Wallace King) to do all the design specs for the arduous South African conditions.

The text in the ad does not refer to the 5E1, but correctly to the 3E. If my memory serves me correctly, this particular order was placed in 1953 for the 3E’s. When they were shipped to South Africa, they were unloaded in Durban, where my father had frequently to go to supervise the commissioning and testing of the locomotives. If these trips coincided with my school holidays, he would take me with him. His ‘in-laws’, my grandparents lived a short distance outside of Durban. We would ‘chase’ locomotives that were already in service to get pictures that could be sent back to Trafford Park in order to have them for publicity purposes. Met Vick’s South African Office was in Johannesburg, where, of course, I grew up. Naturally I recognize that the picture of the 3E is in Johannesburg station. It is entirely possible (if not almost certain!) that the picture was taken by my father.

![]()

WDL Posting by Steve Palmano October 8th 2018.

In respect of the rivalry between BTH and M-V, and their pursuit of independent paths, perhaps symbolic was M-V’s formation of the joint venture with Beyer, Peacock in 1949 (M-V-BP) with the objective of supplying complete electric and diesel-electric locomotives, in which BTH played no part. The conventional approximation is that one third of the value of a diesel-electric locomotive resides in each of the engine, the electric transmission and the mechanical parts. So by having the joint venture build the mechanical parts and assemble the locomotives, M-V’s share of the total value was increased to half. In that case the initiative may have come from Beyer-Peacock, who had been rebuffed by English Electric when it made a similar proposal for a joint venture. Still, one could say that AEI top management was perhaps remiss in letting M-V go ahead without including BTH, and so improving the chances that the joint venture would reach “critical mass”. At the time the UK locomotive building industry was not short of capacity overall, although its distribution may not have been optimum. As a partner, B-P was known for good fit and finish, but it had no experience with modern traction, and was also known for clinging to some outmoded mechanical ideas.

The M-V-BP joint venture was wound up early in 1961, ostensibly for lack of orders and without anticipation that the situation would change. Apparently it had never been fully occupied. At the time M-V-BP had just built 100 out of 135 5E1 class electric locomotives ordered from M-V by South African Railways. The remaining 35 were built by Metro-Cammell (M-C). That looks as if it were a change of plan, as a 1960 May AEI brochure on the 5E1 class stated that all 135 were to be built by the M-V-BP joint venture. Perhaps AEI management pushed for or even engineered the closure of the joint venture, but nonetheless no doubt it was a welcome step in their plans to integrate BTH and M-V.

As previously said, M-V had placed the mechanical work associated with 94-locomotive CIE A- and C-class orders with M-C rather than with M-V-BP, even though the latter surely had the capacity to do it. In this case, M-V also itself undertook the final assembly work in premises rented for the purpose. Again one might have expected a more disciplined AEI top management to require that M-V use joint venture capacity unless there were cogent reasons to do otherwise. Possibly CIE had insisted that M-C be used, but that seems unlikely. Anyway, the last part of the SAR class 5E1 order seems to have established M-V’s relationship with M-C, who thereafter became AEI’s mechanical parts and assembly partner.

Another apparent anomaly was the CIE B class, in that they were built by BRCW, not by M-V-BP. These used spare Sulzer engines previously built for CIE’s abortive twin-engined 1800 hp proposal. M-V had been the electrical equipment supplier for CIE’s home-built, Sulzer-engined prototypes, although in that case it was effectively subcontracting to Sulzer, who had the contract for the whole powertrain. It could have been the same with the B class, whereupon Sulzer (and CIE, of course) would have had a say in the choice of builder, but less so M-V. And Sulzer had an established relationship with BRCW.

It would appear that British Railways treated BTH and M-V as separate entities when it came to assignment of its Pilot Plan electrical equipment business. BTH got 30 locomotive-sets of equipment, as did EE and CP. M-V, Brush and GEC each got 20. So the AEI group had a total of 50, well ahead of the others. All five of the British electric traction equipment suppliers were represented in the Pilot Plan. Interestingly though, in 1953, when British Railways had wanted to diversify the powertrain supply base for its standard shunter, normally EE-equipped, M-V was left out of the allocations. BTH equipped one batch, fitted with Lister-Blackstone engines. This may have been BTH’s first meeting with Lister-Blackstone, an acquaintance that was renewed in 1959 for the Explorer prototype. GEC equipped another batch, also with Lister-Blackstone engines. And a third batch was equipped by Crompton Parkinson, with Crossley engines, perhaps surprising given the established relationship between M-V and Crossley. On the other hand, M-V was then busy supplying the equipment for the EM1 and EM2 class DC electric locomotives, so perhaps British Railways saw the overall situation as being reasonably balanced.

The two BTH Pilot Plan contracts involved the only two locomotive designs that could be said to be closely (rather than generally) duplicated by those of other makers, namely Class 15, duplicated by the NBL-GEC/Paxman Class 16, and the Class 24, duplicated by the BRCW/Sulzer/CP Class 26. The 15 and 16 were both derived from the LMS-conceived NBL/Paxman/BTH prototype #10800. BTH retained the key dimensions (length, bogie centres, bogie wheelbase) of 10800, but used a different bogie design. NBL varied the dimensions, but used the same bogie design as 10800.

That BTH got the Sulzer-engined Class 24 business had a curious aspect, given that there was no previous association between BTH and Sulzer. M-V may have been a more obvious choice, given its prior work with Sulzer on the CIE locomotives. But on the one hand M-V may have been focussed on offering locomotives that used the Crossley engine and which could be built by M-V-BP. On the other hand, it seemed that BR/LMR was intent on a dieselization programme that involved just two mainline types, both with Sulzer engines (one with the 6LDA28 and the other with the 12LDA28) and which it could build in its own workshops. For BTH, which necessarily had to work with a third party mechanical parts supplier, working with British Railways conceptually would have been little different to working with a commercial party. For the Class 24, BTH was the powertrain supplier with Sulzer as engine subcontractor.

Turning to the AEI agreement with Alco, that might have been negotiated by AEI rather than by BTH or M-V individually. It was announced in a DRT 1959 December news brief as follows:

“Alco-A.E.I. – At the beginning of November, Alco Products Inc. announced that it concluded an agreement with Associated Electrical Industries Limited of London, for collaboration in the design manufacture and sale of diesel-electric locomotives for world markets, to be effective at once, and covering locomotives of 900 h.p. upwards. Metro-Vick and British Thomson-Houston are included in the A.E.I. group.”

This was just before the 1960 January 1st effective date of the BTH and M-V “merger”. Clearly, this arrangement with Alco depended upon the established relationship between BTH and GE, in which the former had what seemed to be fairly free access to the latter’s technology. On the other hand, some of the Alco-specific electrical machines involved, namely the main and auxiliary generators, had designations that were in the established M-V series, with TG prefixes for the main generators and AG prefixes for the auxiliary generators and exciters. Perhaps they were built at Trafford Park rather than at Rugby, and so were simply designations in the established plant series. An oddity was that M-V had not used separate exciters on its diesel-electric locomotives, whereas BTH had done so on some of its productions. The AEI traction motors for Alco locomotives were numbered in the 1xx (165) and 2xx (253) series, which both BTH and M-V had previously used. I recall reading somewhere that the 253 was built at Trafford Park, but I cannot now trace wherefrom this came.

The Australian connection may also have paved the way to the agreement. There the electrical equipment supplier for Goodwin-Alco locomotives was “AEI Australia”, where AEI stood for :Australian Electrical Industries, a name that had been used since 1955, when AEI (UK) bought out GE’s interest in Australian GE (AGE) and quickly renamed it. From 1955 AEI Australia continued to build both GE- and AEI-origin electrical equipment side-by-side, and likely it was interested in being able to offer both to Goodwin, so could have lobbied for the agreement. On some of the Goodwin-Alco builds, there was “mixing-and-matching” of AEI and GE equipment. It would appear that NSWGR found that the AEI 253 motor was better than the GE 761 to which it was counterpart.

One would expect that the scope of the potential Alco business would have been an incentive to improve discipline within AEI.

Whether because they pursued independent paths or because of a desire to do differently, BTH and M-V found themselves on opposite sides of the BR Pilot Plan MU system divide. BR had – quite commendably - wanted a common control and MU system for all of the Pilot Plan diesel-electric locomotives. EE, Sulzer, CP and BTH had all agreed on a suitable system that was effectively a blending of the latest EE and Sulzer systems, both based upon pneumatic throttle control. EE used pneumatic control throughout the whole power range, whereas Sulzer used a small number (between 3 and 6) electrically controlled starting notches followed by pneumatic control through the running range. The combined system allowed for optional use of (up to) 3 starting notches, and also catered for full-range pneumatic control, with full interworking capability, thus covering both the EE and Sulzer protocols. CP was already familiar with the Sulzer system from the CR NSU and SLDC locomotives, so its acquiescence was logical. Effectively BTH had little choice, since Sulzer pretty much dictated terms when it came to control systems. And Sulzer surely would have wanted its latest control system used on the Class 24, as well as commonality with the CP-equipped classes 26 and 44.

In the event, before any deliveries were made to BR, Sulzer further updated its engine governor to allow pneumatic control over the whole working range, and the Sulzer-engined Pilot Plan locomotives were all so-fitted. That would appear to have made the provision for starting notches redundant. However, BTH had chosen to use them on its Class 15 design, so they remained a feature of the BR “electropneumatic” (“EP”, later known as “Blue Star”) control/MU system. One could say that BTH practice encompassed both options within the scope of the EP system. It also used the Class 15 type control in its Explorer prototype, suggesting that it saw merit in this approach.

In contrast, reputedly M-V dug its heels in and said no to this EP control and MU system, preferring stepped electric throttle control. It had been introduced to that form when it supplied the equipment for the two CIE prototypes. These used the then-current Sulzer 10-notch electric throttle control system, developed in 1939, which had two starting notches at minimum engine speed followed by 8 running notches at progressively stepped engine speeds through to maximum. M-V then used a slightly modified version, with 3 starting and 7 running notches, on the WAGR and CIE Crossley-engined locomotives. It appears that once it had argued for a second BR MU system, based upon electric throttle control, it was joined by Brush and GEC, who had both used this form for their previous productions. BR may have found it hard to resist given that one of the Pilot Plan objectives was to evaluate a variety of technologies. So for the Pilot Plan it allowed a second control and MU system with 10-notch control based upon 8 engine speeds, somewhat like the 1939 Sulzer system. M-V used this BR “electromagnetic” (“EM”, later “Red Circle”) system on its Crossley-engined Class 28.

Nonetheless, BR subsequently standardized on its EP system for production locomotives, albeit that the first production batch of the NBL/MAN/GEC Class 21 “escaped” this dictum. Brush and GEC appeared to have no problem with swinging over to the EP system. But one wonders what conflict there might have been had M-V been awarded some production orders by BR, and was told to use the EP system.

Be that as it may, the M-V viewpoint on control systems was evidently not persuasive within the merged AEI Traction organization. The Zambesi type, as built for Malawi, had fully pneumatic throttle control, as on the BR Classes 24 and 25. From the photographic evidence, it also had what looks to have been the same master controller as used on the Class 25, but turned around to suit the right-hand driving position of the Zambesi. Not developing a mirror-image master controller does look like corner-cutting, but BTH had done the same with the Explorer prototype, which had a turned-around the same earlier design of master controller as was used on the Classes 15 and 24.

The Nigerian 1401 class derivative of the Zambesi did have 8-notch electric throttle control, but this was not due to a residue of M-V influence, but rather NRC’s idea that it might want to operate these locomotives in MU with its earlier 1101 class EMD G12 fleet, although that never happened. It had control stands that look to have been very similar to those that AEI fitted to Alco locomotives. The CR NT was required to be backwardly MU compatible with the NSU class, so it had the same Sulzer-type control system (with 4 starting notches followed by pneumatic throttle control). It had the left-hand drive version of the Alco-type control stand. Here AEI offered a mirror-image pair, but in this case it had to, as Alco itself had established that precedent, and the Australian standard and broad gauge roads, being left-hand drive, would surely have expected it.

![]()

WDL Posting by Steve Palmano October 30th 2018 The Explorer Locomotive & AEI.

Moving from the bigger picture to the locomotive-specific, perhaps a closer look at the BTH Explorer would provide some insights into AEI and the export business.

The BTH ‘Explorer’ prototype of 1959 appears to have been the outcome of a determined effort to break into the export market for line-service diesel-electric locomotives by having a suitable product to show. Hitherto BTH had completed two export orders for other than shunting locomotives, namely the NSWGR 41 class, for which Metro-Cammell built the mechanical parts, and the WAGR Y class, for which Clayton was the mechanical side partner. Both were heavy shunting, transfer and light line-service locomotives fitted with Paxman engines of relatively modest power output, and both were designed to meet specific customer requirements. The NSWGR 41 turned out to be problematical, and the WAGR Y was hardly an outstanding design. So BTH could not point to much of a successful history in the line-service locomotive business.

The Explorer was fully described in a DRT article in the 1959 April issue, p.151ff. The opening part of that article is worth quoting, because it does convey BTH’s intent:

“From time to time various locomotive builders throughout the world have built at their own cost prototype or demonstration diesel locomotives of new or improved design for trial on one or more railways, in the hope that successful performance would lead to substantial orders on a commercial basis. The latest locomotive built on this basis is a Co-Co, constructed to the account of the British Thomson-Houston Co. Ltd. and Lister-Blackstone Rail Traction Ltd., with the mechanical portion built by the Clayton Equipment Co. Ltd. as a sub-contractor.

“The object of construction was to provide a light general-purpose locomotive for overseas railways, and which would introduce to practical traction work the new Lister-Blackstone twin-bank engine in conjunction with B.T.H electrical equipment. The locomotive designers had in mind more particularly those railways of somewhat light construction in regard to rails and bridges, and of an alignment governed by first cost rather than by subsequent operating economy. Probably on most of such railways heavy freight trains are run at low or medium speeds; and the small number of passenger trains are slow by European standards, generally due to limitations of the track itself. Many of these railways are of a track gauge smaller than the standard 4 ft. 8½ in., and almost all are restricted to light axle loads. These conditions apply in many parts of the world, particularly in the tropics, so that provision has to be made for operating at high ambient temperatures, and maybe also at high altitudes. By fixing the maximum engine output to 1,100 b.h.p. in this particular locomotive, it became possible to sustain the output at sea-level in an ambient temperature of 120 deg. F., or up to an altitude of 4,000 ft. at an ambient of 80-85 deg. F.”

Configuring the Explorer as a “light, general-purpose” design might have been something of a forced choice, dictated by the power output of the Lister-Blackstone engine. But one of the objectives was to introduce the particular Lister-Blackstone engine to traction service, and Lister-Blackstone was a joint sponsor of the project, so that that was a given.

At that time, BTH was involved supplying the powertrain equipment for BR’s own-build Type 2 (later Class 24) design, for which the Sulzer 6LDA28 engine was used, initially set at 1160 hp. Given that the Sulzer engine was well-known and service-proven, one may wonder why BTH did not choose that for its prototype rather than the relatively unknown Lister-Blackstone unit. But Sulzer had no need to sponsor a prototype locomotive powered by its 6LDA28 engine, so for that option, BTH would have had to have been the sole sponsor. Not only that, but Sulzer was, with BRCW and Crompton Parkinson, a member of a tripartite that offered a standard 6LDA28-powered export locomotive. So it might have been reluctant to involve itself in another venture that could be seen as competing with the tripartite. For BTH, Lister-Blackstone may have been the “only game in town”. The Paxman high-speed engine range, also used by BTH, did not at that time extend sufficiently far up the power range. And Paxman’s larger medium-speed model, the YL, was untried in railway service. Also, Paxman appeared to want to remain “neutral”, supplying engines to any builder but not wanting to align with any one in particular, so it was unlikely to jointly sponsor a prototype.

One could say that the whilst Lister-Blackstone participation facilitated the Explorer project, the use of its engine may well have inhibited its sales. As well as being untried, it was of unusual twin-bank design. The crankshaft is typically the costliest single component of a locomotive diesel engine (and one that is also difficult and costly to transport internationally as a spare part), and the Lister-Blackstone engine had two of them. Furthermore, whilst 12 cylinders would have been considered normal and reasonable for a high-speed engine of its power output, that count was in the late 1950s was excessive for a medium-speed engine of 1100 hp, which power level was typically obtained with just 6 or 8 cylinders.

BTH chose the road-switcher form, which was in line with the prevailing practice for export locomotives at the time. Its rationale was captured in the above-mentioned DRT article:

“The locomotive is of the narrow-hood type with a single cab located towards one end; this type has been adopted mainly due to consideration of maintenance under conditions of high ambient temperature. The removable doors and roof sections provide maximum accessibility to all parts requiring regular inspection and maintenance.”

Whilst that was true, there were nevertheless some potential customers who still preferred cab units, particularly those who operated in very dusty environments. An oddity was that the long hood was considered to be the front end, although it did not matter much, as the Explorer’s cab was fitted out for bidirectional operation, with diagonally opposite driving stations. By the late 1950s, the prevailing convention was that the short hood was the front end of a road-switcher.

Given that light axle loading was one of the design objectives, it was almost inevitable that six axles would be used, and BTH’s choice to have all axles motored, and so the Co-Co wheel arrangement, was in keeping with the trend of the time. For example, GE had set its face against the A1A-A1A form for its export Universal range, and although Alco offered it as an option on its standard export range, there were no takers.

Thus the Explorer was an 1100/1030 hp road-switcher with the Co-Co wheel arrangement that weighed 72 (long) tons in standard form but could be built up to 84 tons if required. It was built for the metre gauge, but could be supplied in any gauge upwards from there to 5’ 6”. Length over headstocks was 46’0”. Overall height and width were 12’9” and 9’9”. The latter were not unusual in CM-gauge practice, but certainly larger than the 12’0” and 9’0” numbers chosen by GE for its export Universals. Bogie wheelbase was 12’0”, quite typical in the CM-gauge world, total wheelbase was 36’0”, and bogie pivot centres were at 30’0”, indicating pivots that were well offset in the outwards direction.

As per customary practice, the engine-generator set, which was rather long, was mounted centrally, with the generator end adjacent to the cab. The cooling group was mounted in the end compartment of the long hood. However, it occupied only the upper half. The lower half housed one of the motor-driven traction motor blowers, one of the motor-driven vacuum exhausters, and the pair of crossflow dynamic brake units. Access to these units for inspection and maintenance may have been somewhat restricted, and low mounting of the heat-producing dynamic brake units was certainly unusual. Between the end compartment and the engine were a pair of shaft-driven compressors. The engine had two crankshafts, and so two power take-offs were available at the free end, each driving one of the compressors.

The cooling group had half-height vertical panel radiators on each side, with two vertical-shaft motor-driven fans. Mechanically-driven fans were more common on export designs, and BTH had used such in its Type 1 (later Class 15) road-switcher design for BR. However, the two-layer construction of the end-compartment with the bottom layer full of machinery probably precluded the mechanical drive option. BTH had used a motor-driven cooling fan on the BR Class 24 design, so was familiar with this approach.

The short hood was also of two-layer construction, something that BTH had previously used in the BR Type 1. In this case, the upper part housed two longitudinally mounted control frames, one on each side. One was the main control frame and the other was for the dynamic brake. In the lower compartment were the other traction motor blower and the other exhauster. As with the end compartment, access looks to have been somewhat restricted.

The Lister-Blackstone ERS12T engine had two banks, each with six 8.75 inch bore and 11.5 inch stroke cylinders. Crankshaft speed was 800 rev/min, mean piston speed was 1530 ft/min, and mean effective pressure was 143 lbf/in². The latter two numbers were quite modest. At the upper end of the range then found in railway practice was the GE/Cooper Bessemer FVBL engine, with numbers of 1750 ft/min and 196 lbf/in². The Alco 251 had essentially similar numbers.

The crankshaft phasing gears also provided a step-up, so that the output shaft ran at 1125 rev/min, thus allowing for a smaller and lighter main generator than would have been the case at 800 rev/min. These gears were contained in a casing between the engine and the main generator which was about as long as the main generator itself, this contributing to the long overall length of the combination. Given that this engine was used with a conventional single-bearing generator, the long casing may have been desirable to allow adequate bearing support for the generator. Included in the assembly was uncoupling gear that in an emergency allowed one bank of the engine to be shut down whilst the other continued in operation. Thus each bank of the engine had its own governor with external pneumatic speed control, although with interconnected rack linkage to ensure power balancing. This provision probably involved more complexity than might have been expected in a general-purpose locomotive.

The BTH RTB14440 main generator was a 10-pole machine. According to normal British practice, the 110-volt auxiliary generator was overhung and of 48 kW capacity. The latter was quite high. As well as supplying the traction motor blowers and exhausters per normal British practice, it also supplied the cooling fan motors. A separator exciter was used, mounted on the auxiliary generator and belt driven from the end of the latter. At the time, BTH practice was similar to that of GE, with whom it had a close relationship, in that it used differential exciters, although that did change in the early 1960s. The overhung auxiliary generator and exciter belt drive also contributed to the large overall length of the whole set. Perhaps a more conventional unit would have allowed more main compartment space to accommodate some of the auxiliaries, in turn avoiding the need to double-deck the end compartment.

The traction motors were four-pole machines, model number unknown but possibly BTH 136. They were connected in permanent 6P with one stage of field weakening, and drove 36½ inch wheels via resilient gearing of 66:13 ratio. Maximum safe speed was 55 mile/h. BTH evidently favoured all-parallel traction motor connections. At least that is what had had used for the NSWGR 41, WAGR Y, BR 24 and BR 15, although preceding all of these the LMS/BR prototype #10800 had used the 2S2P connection. Starting tractive effort was 42 000 lbf. This was 26% adhesion, so it may well have been the equipment limited rather than the adhesion limited number. Continuous tractive effort was 24 000 lbf at 11.8 mile/h.

The bogies were of unusual design, employing some Alsthom features although I don’t think that they corresponded overall with any specific Alsthom design. They were of the fabricated box-section type, with Alsthom rubber cone pivots. Each bogie had two such pivots, positioned over the cross-members which were half-way between adjacent axles. The inner pivot was mounted in such a way that allowed lateral sliding motion, so that the outer pivot formed the rotational centre. Load was transferred to the bogie by four side bearers that rested on coil springs at the end of the above-mentioned cross-members, this forming the secondary suspension. Instead of the customary pedestals, the axleboxes were each located by a Watt linkage, which allowed some lateral resilience, also a feature much used by Alsthom. Load was transferred to the axleboxes by coil primary springs and underslung equalizing beams. The motors were mounted conventionally, with two inward and one outward facing in each bogie, with the inner pair adjacent. Overall one could say that this bogie was intended to allow good flexibility for use over indifferent track without undue complication, and in particular without the use of a separate bolster. There was sufficient space between the bogies for an underslung fuel tank.

For the power control system, BTH essentially used that which it used on the BR Class 15. Thus there were three electrically controlled starting notches followed by continuously variable power control by pneumatically controlled engine speed. Although not shown in the accompanying schematic, the DRT article noted that engine governor-driven load control was incorporated. Quite how that was done with two governors is unknown, but I’d guess that the floating lever and pilot valve mechanism were external to the governors. Dynamic braking control was done in a fairly direct manner with rheostats (one at each driving position) in series with the exciter battery field. The Explorer was equipped for MU operation of up to three units, but of course it never had another of its type with which to do this.

As mentioned, the cab had diagonally opposite driving stations, arranged for right-hand drive. Each had the same type of control stand as had been used for the BR 15 and 24, which were left-hand drive. But instead of a mirror-image version of the control stand, the photographic evidence indicates that BTH simply rotated the left-hand drive version approximately 180 degrees to suit right-hand drive operation, with consequent opposite direction operation of the handles. One could view this as having been a temporary expedient for the prototype, with the intent that a mirror-image control stand would be developed for the production version. The control stand had throttle and master handles, the latter with off, reverse, engine only and forward positions, and engine start and stop buttons. The dynamic brake was controlled by a handle on top of a separate small control column ahead of the driver’s seat. Again that might have been a temporary expedient, with the expectation that for production versions, the dynamic brake control would be incorporated in the main control stand.

The Explorer was fitted with air brakes, and equipped for both air and vacuum train braking. Unusually, it had separate handles for the automatic air and vacuum brakes, as well as a straight air brake handle for the locomotive brakes. Typically dual-braked locomotives had train braking control via an automatic air brake handle that also controlled the train vacuum brake via a proportional relay valve. Possibly such systems were not readily available from UK suppliers when the Explorer was designed, although not long thereafter Davies & Metcalf offered such a product, as was used on the BR Class 33. Also, it may have been thought that production locomotives would have either air or vacuum train brakes, but not both, so the prototype was laid out with each as they would be used in practice, rather than using a combined system that would be unlikely to be required in production. The use of two-speed motor-driven exhausters for the vacuum brake was standard British practice, these being regarded as superior to the engine-driven expressors used in American practice.

The mechanical parts were built, and the locomotive was assembled by Clayton, who had a reputation for poor workmanship. Whether this afflicted the Explorer is unknown; possibly a special effort was made by BTH to ensure that Clayton did a good job.

Who BTH saw as prospective customers for the Explorer is not recorded. The African roads with British connections were surely in view though, and this group would have included the railway systems in Ghana, Nigeria, Sudan, the East African group and Rhodesia-Nyasaland amongst others. Elsewhere Malaya might have been a possibility. Without local manufacture, Australia was closed. New Zealand dieselization was at the time moving along an EMD vector that probably left no room for a BTH line-service locomotive, although of course NZR did acquire a fleet of BTH/Rolls Royce/Clayton Dsc class shunters in 1959.

Be that as it may, BTH surely saw EAR as a strong prospect. The Explorer was built to the metre gauge and fitted with EAR-type couplers, namely the low-mounted chopper type. Its fitment with air as well as vacuum brakes may have been to suit EAR, which unlike most African CM-gauge roads, was air braked, although at the time I think that the Tanganyika section was still vacuum-braked. Right-hand drive matched the EAR requirements, but then most of the prospects were right-hand drive roads. It was also fitted with dynamic braking. This was anyway an essential option in the world marketplace, but particularly important for EAR, whose system had long gradients where it could be used to advantage.

EAR had developed a preliminary dieselization plan in 1957, as reported in DRT 1958 June. That involved three locomotive types. One was a large model of 1800 to 2000 hp suitable for operation of main lines laid with 80 lb/yard rails. Another was a medium-sized model of 1100 to 1400 hp., and the third was a small model of 1000 hp. It is reasonable to assume that the medium-sized model would need to have been suitable for operation over tracks laid with 55 lb/yard or even lighter rails. The DRT 1958 June article mentioned that the 1957 report indicated that 15 large and 8 medium locomotives would be required to dieselize the Nairobi to Nakuru section. But a later article in DRT 1960 October, primarily about the then-new EE-built 90 class, noted right at the end that the 1957 report had stated totals of 15 large and 22 medium locomotives would be required for dieselization of the Nairobi to Nakuru and Nakuru to Kisumu sections. I suspect that BTH had the 22 medium locomotive requirement well in mind when it designed the Explorer.

As it turned out, EAR did differently, and its initial order, announced in DRT 1958 October, and discussed in more detail in DRT 1958 November, was for a high-powered, low axle-loading “universal” locomotive, suitable for operation over the whole Nairobi to Nakuru to Kisumu section, namely the EE-built 90 class. Whether BTH bid for this business, and if so, what engine it chose, is unknown, although the Paxman YL in 12-cylinder form would be my best guess. Thus by the time the Explorer arrived in Kenya in mid-1959, it was well away from EAR’s immediate requirements. EAR did not look again at medium locomotives until the mid-1960s, by which time its specific requirements had changed. AEI bid a modified version of the Zambesi, but lost out to EE.

Of the other prospects, Ghana and Nigeria had started dieselization in 1955 with 750 hp EE locomotives. Both migrated to 1425 hp “medium” locomotives around 1959-60. Probably the respective orders were placed before BTH was ready, and their power requirements were somewhat above what the Explorer originally offered, although development of the Lister-Blackstone engine to that level would not have been unexpected had it actually entered fleet service. But Nigeria did choose a modified AEI Zambesi for its second group of 1400 hp medium locomotives in the mid-1960s. Rhodesia had started with “large” locomotives, and continued down that pathway up until UDI, just before which it had switched to GE as supplier, probably influenced by SAR’s good experience with this make. Zambia also started with GE as supplier in the mid-1950s. Nyasaland started its dieselization in 1963 with “medium” locomotives, for which AEI developed the Zambesi. Sudan was another railway that started with “large” diesel locomotives from EE, not acquiring any of the “medium” type until the mid-1960s, for which it turned to Hitachi as supplier. KTM Malaya had started with the “large” type in 1957, and when it wanted “medium” locomotives in the mid-1960s, by which time Malaya had become Malaysia, it chose a KSK diesel-hydraulic design.

In the 1960s, amongst the prospective customers who might be inclined to buy British-built locomotives, the market for “medium” British locomotives turned out to be quite a bit smaller than that for “large” British locomotives. Amongst British exports, EE dominated the latter class, but AEI did better than EE in the “medium” class, with its Zambesi design. Insofar as the latter was the notional successor to the Explorer, then one could say that BTH had been prudent in choosing the “medium” category for its prototype. Regardless of the merits or otherwise of the Explorer design, it would appear that its intended market did not in fact materialize until the early-to-mid 1960s, by which time AEI was able to offer the Zambesi with a more conventional and well-known powerplant. The Zambesi was enabled by a concatenation of events such that it might be said to have had partible paternity.

Locomotives for the “export” markets at interest were seldom bought solely on the basis of engineering assessments. Often, pricing, and particularly financing arrangements took precedence, and sometimes there were political considerations. Still, I imagine that any potential customer undertaking an engineering assessment of the Explorer would have been concerned about its rather complex engine that lacked any operating experience in the railway environment, and also about its equipment layout, with double-decking of the end and nose compartments. Both of these problems were mostly avoided in the other similar category products on offer at the time.

In 1959, the American builders offered standard models in the six-motor “medium” category, all available for CMT gauges. GE had the 990/900 hp U9C with 6-cylinder engine at 76 tons, and the 1320/1200 hp U12C with 8-cylinder engine at 78½ tons. Both of these were somewhat heavier than the Explorer. Alco offered the simpler DL-531, 975/900 hp with 6-cylinder engine at 67 tons, lighter but less powerful than the Explorer. EMD’s smallest 6-motor offering at the time was the 1425/1310 hp GR12 with 12-cylinder engine, at 85 tons. This was really in a weight class above the Explorer.

Amongst the British builders, BRCW offered a standard design of cab unit type fitted with the Sulzer 6LDA28 engine and Crompton Parkinson electrical equipment, and with A1A-A1A running gear, suitable for metre gauge and upwards. It was first built for CR in 1954 at 63 tons and then for SLDC, Sierra Leone in 1955 at 72 tons, of which 52 tons was adhesive. BRCW had described it as a standard design in DRT 1952 May, at which time the continuous output of the Sulzer 6LDA28 engine was 925 hp. By 1959 that had increased to 1160 hp. There was provision for the inclusion of a dynamic brake unit in the nose section, although that may not have been an ideal location for it. Probably a six-motor version could have been built. That would have required longer-wheelbase bogies, say 11’6” rather than 10’0”, which in turn might have required some frame lengthening. Given the 63 tons base weight for the A1A-A1A version, that might just have been doable without going above 72 tons. As it turned out, the Zambesi was also the effective successor to this design, after the demise of BRCW.

EE had a cab-hood model with A1A-A1A running gear based upon its 8SRKT engine, which it had sold to metre-gauge operators in Brasil and Argentina. It weighed in at 72 tons. A six-motor version would easily have been possible without increasing the 12’0” bogie wheelbase. There was also enough room to have added one of EE’s crossflow type dynamic brake units. With those additions weight would probably have gone over 80 tons, although some saving might have been obtained by using the 8SVT engine rather than the 8SRKT. By 1959 these produced 1100 hp, with 1250 hp available from the 8CSVT and 8CSRKT. EE did not build any more of this model after 1959. The mainstay of its CM-gauge export business in the 1960s was its range of 12-cylinder models.

MetroVick was probably out of options in 1959, given the demonstrated unsatisfactory nature of the Crossley engine. Otherwise, its CIE A class design might have been adaptable to CM gauge applications. At 12’0” high and 8’10” wide, it would have fitted quite a few CM-gauge profiles. With CM-gauge bogies and metre-gauge motors, its weight might have come back a bit, say from 87 to 85 tons, but it would have remained in a weight class above the Explorer. Adding dynamic braking equipment might have been something of a “shoehorn” job, though.

Brush was something of a single act when it came to export models, for which it used the Mirrlees JVS12T engine. This would have put CM-gauge Co-Co locomotives so-powered at around the 90-ton mark, and so well above where the Explorer was. In the early 1950s, Brush did propose supplying a single locomotive to QR, Australia, but later withdrew. I have never seen any details of this design, but I understand that it fell into the QR 90-ton group, as did the EE-built 1200 class and the GE-built 1300 (later 1150) class.

Elsewhere in Europe, Alsthom had in 1958 built a six-motor, Bo-Bo-Bo Cape gauge road-switcher for Burma, equipped with the 16-cylinder version of the MGO high-speed engine set at 1200 hp. The basic weight of this design was 60 tons, although for Burma it was built to 66 tons. It was based upon the Alsthom standard end-cab Bo-Bo design that was usually fitted with the 12-cylinder MGO engine.

In 1959, it could be said that the German builders had yet to come up with diesel-hydraulic designs that were really credible in the CM-gauge export market – in fact that did not happen until 1964, when both Henschel and Krupp built light B-B double-cab units that were evidently derived from the DB V160 programme. In 1959 the German builder CM-gauge diesel-hydraulic export efforts to date had often been somewhat clumsy.

So there was certainly some competition, but no more, and probably less than EE faced in the category in which it was offering its 12-cylinder models. One may ask the question as to whether the Explorer might have done better had BTH chosen to use the Sulzer 6LDA28 engine with a resultant improved equipment layout. That would probably have removed some buyer resistance, but it is by no means clear that the sales opportunities for such a British-built locomotive were actually there. Having built 19 of its 6LDA28-powered standard model in 1954-55, BRCW then built just one more, for SLDC in 1960. It could be that a Sulzer-engined Explorer would simply have provided a minimum-design effort segue into the Zambesi when the sales opportunities did arrive.

![]()

WDL Posting by Steve Palmano November 5th 2018 : From Explorer to Zambesi.

The BTH Explorer prototype had appeared just a few months before the BTH (and Metropolitan-Vickers (M-V)) names disappeared from the traction scene and from 1960 January were replaced by the corporate name Associated Electrical Industries (AEI).

The immediate result was that the Explorer was advertised as an AEI locomotive in the early part of 1960. Lister-Blackstone also changes its advertising to indicate that the electrical equipment supplier was AEI.

As mentioned, the Explorer did not attract any orders. Rather the first order was for its successor, the Zambesi type.

The AEI/Sulzer/Metropolitan-Cammell (M-C) Zambesi type export model, first delivered in 1963, was de jure the successor to the Explorer. Sulzer probably also saw it as the de facto successor to the BRCW/Sulzer/CP standard export model. That notion eventually played out along a slightly different vector, and one that resulted in the Commonwealth Railways (CR), Australia NT class, to be considered later in this series.

The initial order for the Zambesi type was placed in 1962 March jointly by Nyasaland Railways (NR), for 5 units, and Trans-Zambesia Railways (TZR), for 3 units, these being the first line-service diesel locomotives for both of these organizations. All 8 were intended for use on the jointly operated Nyasaland and Trans-Zambesia Railways, a combination of both systems which abutted at the Zambesi river crossing at the Nyasaland-Mozambique border. Presumably that river also gave rise to the NR/TZR class name. The ‘Zambesi’ name has also been used informally as a generic for the basic design, although not as far as I can tell by AEI, Sulzer or M-C, who used it only for the NR/TZR variant.

A news brief in Diesel Railway Traction (DRT) 1962 September recorded that the locomotives were being acquired on deferred payment terms, and that they were to be of the “latest Sulzer-AEI diesel-electric type”. That suggests that financing arrangements as well as technical considerations played a part in the choice of supplier. It seems likely that in 1962, before Nyasaland gained full independence from the UK and became Malawi, British sourcing would have been strongly preferred.

It is unknown whether AEI’s gaining of this business was the outcome of a tendering process, but if it was, then the other British bidders would very likely have included English Electric (EE) and Brush. One could imagine EE offering a suitable locomotive powered by its 8CSVT (or perhaps 8CSRKT) engine, which at the time could have provided 1200 hp in a tropical, medium-altitude environment. For Brush, choice of powerplant might have been a problem. The Mirrlees JVS12T was really too big and heavy for the application. There was an 8-cylinder engine in the JVSST series, for which one could impute a site rating of around 1150 hp. This variant may or may not have some marine and/or industrial service history, but it had no rail traction service history. And 45-degree V8 engines were known as difficult to get right in the balancing department, and if that was not right, durability could be adversely affected. So it would have been outside the boundaries of prudent choice.

AEI would have been able to claim that most elements of its design were service-proven. The Sulzer 6LDA28 engine was in any event well-known, and the combination of that with the BTH main generator was used in a large number of BR Class 24 and 25 locomotives. The AEI 253 traction motor, although in and of itself fairly new, was based upon an established and highly-regarded GE design with which it was interchangeable for use in Alco locomotives. (Later evidence from the NSWGR experience suggested that the AEI version might even have been better.) Mechanical elements such as the bogie design were in-service on the Explorer prototype.

Conceptually, as a medium-powered export locomotive, the Zambesi was not much different to the Explorer, but a significant difference in practice was its use of a Sulzer 6-cylinder rather than the Lister-Blackstone 12-cylinder engine, which no doubt increased its customer appeal. M-C as mechanical parts builder was a probably a better choice than Clayton in the eyes of potential customers.

Considering the change of participants from AEI/Lister-Blackstone/Clayton to AEI/Sulzer/M-C requires a look at the complex of relationships that existed within the British locomotive-building industry during the period at interest.

Switzerland-based Sulzer had arranged in 1948 for the licence building of its engines in the UK by Vickers Armstrong. It was envisaged that the UK, Australasian, South African, Rhodesian and South American markets would be supplied from UK manufacture. In principle Sulzer was prepared to work with any locomotive builder and with any electrical equipment supplier. It supplied (from Switzerland) the engines for two prototypes built by CIE, Ireland, these being equipped by Metropolitan-Vickers (M-V). Thus there was established a connection between M-V and Sulzer. Sulzer also had Vickers Armstrong build 12 engines for a planned CIE own-build twin-engined locomotive programme that was later cancelled.

Early on Sulzer formed a tripartite alliance with BRCW and Crompton Parkinson (CP) whose outcome was a standard export locomotive built for CR, Australia and SLDC, Sierra Leone to a total of 20 units. Exactly when this alliance was formed is not clear, but the CR order for 14 locomotives was recorded in Diesel Railway Traction (DRT) 1951 September. BRCW was the main contractor, but Sulzer had technical responsibility. Apparently the latter was at the insistence of CR, who preferred to buy locomotives from an experienced builder. The SLDC initial order for three units was recorded in DRT 1952 January. The locomotive was briefly described in DRT 1952 May, wherein it was referred to as a “standard” model. It is possible that Sulzer saw this arrangement as putting itself in a position where it needed to give priority to BRCW and CP when it came to export business, but not for domestic business.

After the Sulzer/BRCW/CP arrangement was in place, BRCW built 12 locomotives for CIE using the previously-built Sulzer engines and M-V electrical equipment. Presumably the equipment had been ordered at the same time as the engines. Why BRCW was chosen is unknown, given that by then M-V had its locomotive building own capacity via the M-V-Beyer, Peacock (M-V-BP) joint venture. Possibly that was the Sulzer preference, given the existence of the tripartite. Or perhaps BRCW was simply attractive to CIE on the basis that it could draw much from its Sulzer-engined standard design. Whether incidentally or otherwise, it established a connection between M-V and BRCW.

Sulzer was in favour at BR, particularly in LMR circles, and for its Pilot Plan, that organization chose Sulzer engines for its own-build Type 2 (later Class 24) and Type 4 (later Class 44) designs. For the Class 44 BR chose CP electrical equipment, extending the existing Sulzer-CP relationship. For the Class 24, BTH was the electrical equipment supplier. Given that BTH and M-V operated more-or-less independently at the time, Sulzer-BTH was essentially a new relationship, and one that carried over into the AEI era. Both of these BR-Sulzer Pilot Plan designs became early production models, as Classes 24/25 and 45/46.

The BRCW/Sulzer/CP tripartite also gained BR Pilot Plan and early production business, initially with its Type 2 (later Class 26) design and then with its Type 3 (later Class 33) derivative. It has been said by some that because of BRCW’s attention to design detail, the BRCW/Sulzer Type 2 locomotives were actually somewhat better than BR’s own builds.