1966 - 1967

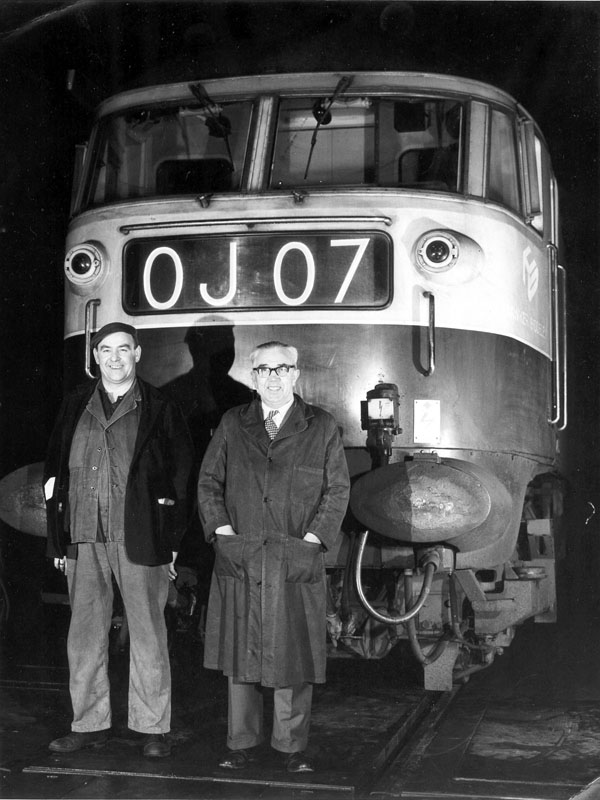

Laid down at the Loughborough works of Brush Traction in 1966 (Brush Works # 711 of 1967) and completed in late 1967 HS4000 'Kestrel'

was a private venture, designed and built by Brush Electrical Engineering Co Ltd, Loughborough in conjunction with Sulzer Bros Ltd. The locomotive was an attempt to install 4,000hp into a single locomotive using the latest AC technology. Cost savings were hoped for over existing twin engined locomotives (BR's Class 52's & 55's) and the USA style building block approach of multiple locomotive consists. The engine installed was not a continuation/uprating of the 12LDA28 found in over seven hundred British Railways locomotives.

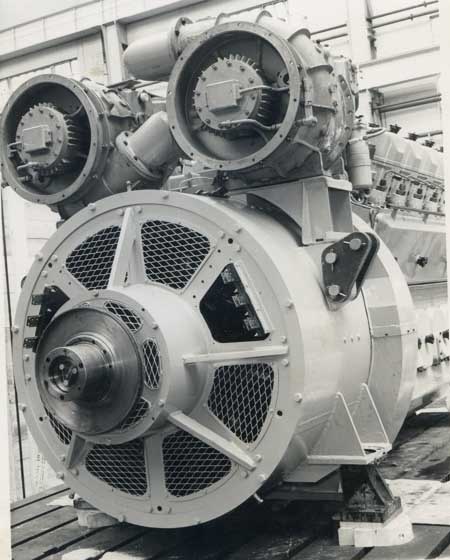

The power unit was a Winterthur built 16LVA24 diesel engine with sixteen cylinders arranged in two banks, 'V' form delivering 4,000hp at 1,100rpm. This was coupled to a Brush alternator/exciter and combined train heat/auxiliary generator. A smaller dynastart unit was also incorporated to motor the engine for starting and provide DC power for battery charging, engine priming pumps, exhausters & compressors.

The main alternator was a ten pole three phase salient pole machine with brushless exciter supplying power for the six traction motors. The AC output was rectified in a bank of eighty four silicon-diode rectifiers, three phase bridge connected. With the engine running at 1,100rpm the AC/DC power system would supply a continuous output of 3,110 amp, 810 volts, 2,520kW or 4,980 amps, 504 volts, 2,510kW according to the loading. The combined train heat/auxiliary alternator, with brushless exciter incorporated three 3 phase stator windings, which supplied the power through rectifiers for the train heating. One of the windings also supplied the power for the auxiliary machines. Output was 533kVA, 680 volts AC at full engine speed.

The exciters for the main alternator and the train heating/auxiliary alternators were of the rotating armature, brushless type, the output being rectified by silicon diodes mounted on an extension of the rotor shaft. Each exciter was secured to its alternator by attachment of the magnet frame to the alternator end frame, the rotor windings in each case being mounted on the extended alternator shaft.

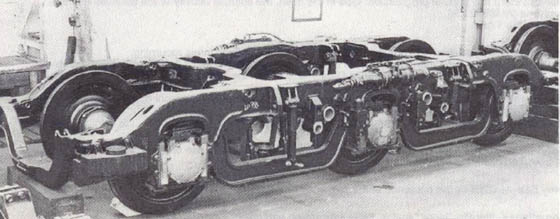

The six traction motors were DC operated four pole series wound machines, force ventilated with 3,000 cubic feet of air per minute, each rated at 515hp, 504 volts, 830 amps at 681rpm, or 509hp, 464 volts, 900 amps at 610 rpm. Each motor was mounted on a suspension tube concentric with the axle it drove and flexibly attached to the bogie frame via a bracket attached to the motor casing. Drive was transmitted to the axle through a spur-type reduction gearing enclosed in an oil bath gear case, the driven gearwheel incorporated bonded rubber units to give torsional resilience to damp out vibration in the drive. The gear ratio chosen would permit a continuous speed of 110mph.

Three phase squirrel cage type machines AC powered from the auxiliary generator powered the radiator cooling fans and the traction motor blowers. DC operated motors powered the compressors, exhausters, priming pumps and the blowers for cooling the dynamic brake resistors.

The braking system was mechanically of conventional design, the operating systems included vacuum, straight air, automatic air and dynamic with hydraulically operated hand & parking brake. Two exhausters & compressors provided air or vacuum for the braking systems. The dynamic braking system was integrated with the air brake system, the former having precedence. Speed was the controlling factor between the operation of the two systems, sensing devices determine the point at which the braking load was transfered between the two systems - the dynamic brake becoming less effective as speed decreased.

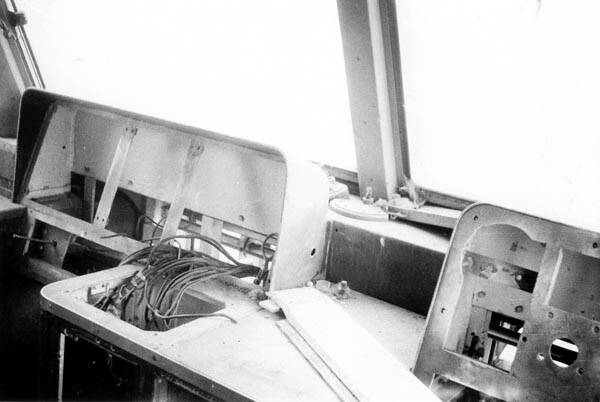

Three small racks with detachable modules incorporating plug-in printed circuit boards formed the core of the solid state control system. Sensing elements (transducers) provided the control system with a variety of readings, from which appropriate action was selected. External sockets allowed for diagnostic fault finding or monitoring during normal operation. Those operations controlled electronically were: load regulation, traction motor field divert, dynamic braking, wheelslip, engine temperature, train heating, overload protection, automatic voltage regulation of the AC & DC circuits.

The body was built along the lines of the many Class 47s produced at Loughborough, with a stressed skin body, there being no conventional underframe or chassis. The cabs received a stylish streamlined treatment.

1968

Unfortunately when HS4000 was sent from the Brush Works, Loughborough to Derby Locomotive Works for weighing on January 20th 1968 one of its major drawbacks was revealed, it weighed 133 tons,

considerably over BR's desired 20 ton per axle limit. Part of the reason for its excessive weight lay with it carrying a considerable amount of prototype equipment.

From Derby 'Kestrel' visited Marylebone on January 29, 1968 for the official handing over ceremony. Initial trials were on the WCML with Shap being used as a test of the locomotive's capabilities. This included taking twenty four coaches (660 tons) over Shap, 46 mph being noted at the summit. In the middle of May 'Kestrel' was allocated to Tinsley (41A) and put through its paces on the many coal workings out of Shirebrook, particularly to Whitemoor, handling two round trips a day, five days a week with coal trains loaded to a maximum of 1600 tons. These workings were:

7J31 (or 7P31?)SX 11.09 Mansfield Colliery Sidings - Whitemoor (due 14.20).

7P31 (or 7J31?)SX 15.10 Whitemoor (Norwood Yard) - Mansfield Colliery Sidings.

7J07 (or 7P07?)SX 19.40 Mansfield Colliery Sidings - Whitemoor (due 22.53).

5P07 (or 5J07?)SX 23.45 Whitemoor (Down Yard) - Thoresby Colliery Jct.

On August 7th 1968 HS4000 worked a test run between Mansfield concentration sidings at Clipstone and Lincoln with a train of 52 loaded merry-go-round wagons of 2,028 tons gross. The speed limit for the wagons was 45mph. The test included the locomotive's ability to restart trains on rising gradients, in particular the 1.5 miles on 1 in 120 at High Marnham. Here, from a standing start 20mph was reached in 6.5 minutes, maintaining this speed until easier gradients were reached.

By mid August 14,000 miles had been covered, with an availability of 88%. At this time it also visited Darlington Bank Top for bogie rotational tests. In August tests on the Mansfield - Lincoln line with coal hopper wagons totalling 2,028 tons were successfully completed under a variety of weather conditions.

In August & September mobile tests were carried out over the Derby-Crewe-Nuneaton-Derby route to test a number of the innovative features carried by this machine. Dynamometer Car M45049 and Mobile Test Unit No 3 M45055 were used, additionally a dead Class 86 (E3132) was added to the formation when operating between Crewe & Nuneaton. The locomotive was noted in the Research Dept yard on August 24th and worked over the Crewe - Nuneaton - Leicester route on 27th/28th/29th.

Following the end of its time at the Research Department and its visit to Derby Works Open Day, HS4000 returned to the coal duties out of Shirebrook, on the Mansfield - Whitemoor route. By the end of 1968 engine hours had reached 1,731 and total mileage was about 26,000.

1969

In May/June 1969 Loughborough fitted Class 47 bogies to 'Kestrel' to bring its overall weight down and allow its use on higher speed passenger workings. Because the traction motors in the Class 47 bogies were smaller the locomotive's continuous rating was reduced. Initially manned by Shirebrook crews and inspectors for these workings, later Finsbury Park crews trained on the locomotive allowing a more intensive use commencing October with trips between Kings Cross and Newcastle.

On July 12th HS4000 was exhibited at Cricklewood depot Open Day, it quickly returned north on the Midland mainline once the Open Day was finished. On July 30th it worked a late morning test train of six coaches from Doncaster to Peterborough and return. Shirebrook crews with a Doncaster pilot manned the locomotive, reaching Doncaster via Tuxford West curve.

On October 18th HS4000 and six coaches were noted on a special at Kings Cross, the locomotive later moving off to Finsbury Park. Regular diagrammed working commenced on October 25th with the 1N08 09.00 Kings Cross - Newcastle and return 1A30. By the 27th it had shifted to the 1N06 07.55 Kings Cross - Newcastle and 1A32 return. On November 10th 1969 HS4000 worked the 16.20 Kings Cross - York stopping service. The train loaded to 334.5 tons with a 7.5 minute late departure. This lost time had been recovered by Huntingdon. In climbing Stoke Bank 99mph was recorded at Little Bytham, here power was eased leading to Corby Glen being passed at 93mph. With full power reapplied Stoke signalbox was passed at 95mph.

1970

HS4000 was noted at Stratford depot on St Patrick's Day 1970, laying over whilst handling the Hull - Stratford freightliner. Maintenance for 'Kestrel' during this period was handled by Tinsley, being noted there on April 5th. It visited Crewe Electric Depot on April 19th as one of the star attractions for the depot's Open Day.

On May 29th 1970 8313 hauled Kestrel from Tinsley to the Vickers Works at Barrow. It set out using the Calder Valley route, Hall Royds Junction, and Copy Pit. After arriving at Rose Grove the LMR refused passage of the duo, with them retreating over the route just travelled, however by the next day Barrow had been reached. The locomotive would remain at Vickers until September 2nd.

After return from the Vickers works HS4000 went back to work on the Mansfield - Whitemoor mineral trains.

1971 - 1993

In June 1971 the locomotive visited the Vickers Armstrong works at Barrow for engine removal and overhaul. Upon release from Vickers it returned to Shirebrook for more Mansfield - Whitemoor freight workings. It's continued stay on BR was brief for the locomotive was sold to the USSR railways. After attention at Crewe Works, it was removed to Cardiff Docks and shipped to Leningrad by the MV Krasnokansk on July 8th 1971 (or also reported as June 8th - 11th 1971). The locomotive was purchased for £127,000. The original asking price was £205,820.00 but presumably since no one else was interested in the locomotive the Russians were able to bargain the price downwards.

During July 1971 an international exhibition 'Railroad Rolling Stock-71' was held in Scherbinka (Shcherbinka) located 17 miles south of Moscow, with HS4000 being present for display. It would then be tested at Scherbinka, after which between April & September 1972 it saw occasional service on Leningrad - Tallinn & Leningrad - Pakov passenger services. By the end of 1972 HS4000 entered the Kolomensky Zavod locomotive works located about 60 miles south-east of Moscow. Whilst here dynamic tests took place and detailed examination of the locomotive and its components also occurred. During 1975 a 4,000hp TEP70 prototype entered traffic, presumably incorporating much of the technology found in HS4000, a second prototype was introduced in 1977, with over 550 of this type eventually entering service.

At some point the power unit was removed from the locomotive and set up in a workshop to allow further tests, of a static nature, to be carried out. The locomotive shell remained intact and was ballasted with concrete, presumably for use as a dead-load vehicle. By the early 1980's it is reported that the locomotive body was suffering severely from corrosion, though it is reported as remaining in service at least until 1986. The remains of Kestrel were scrapped at the Kolomna locomotive workshops during 1993.

Three left views above courtesy Oleg Izmerov, bottom view courtesy BR.

Three views of the gutted locomotive, the first view shows a little of the concrete ballast added to the engine room, the other two show one of the stripped cabs, the instrumentation no doubt transferred to the static test laboratory. The lower view show the cab in better times with BR Driver Sidney Gadsby at the controls.

Further information on HS4000 can be found at 'Memories of a Sulzer Engineer' .

Page added August 24th 2003

Page updated August 24th 2014

Sources:

Hawker Siddeley/Brush publicity material

Railway Observer

Railway Magazine

Keith Fender

Mike Goodall

Brits Abroad - Ken Carr & David Maxey 2009