Like many countries throughout the world at the end of World War Two the CIE had a steam locomotive fleet that was no longer able to satisfactorily handle the its passenger and freight traffic. Its fleet of almost 450 locomotives had suffered from arrears of maintenance, lack of spares, a high average age and the heavy burden imposed by increased traffic throught out the war years. Over one quarter of the fleet were out of service awaiting shopping.

Thus with the hostilities over and a growing global supply of diesel powered locomotives the Board of the CIE approved an order in 1946 for two mixed traffic locomotives and five shunting locomotives. The two 800/1000hp machines were required to haul a 360 ton freight train at 40mph or a 120 ton passenger train at 55mph - starting tractive effort was to be 46,000lb and the one hour rating was 23,000lb at 9.5mph.

Initially the contact had been made in August 1945 with Brush Electrical Engineering Company of Loughborough being asked to supply two diesel electric locomotives at a cost of not more than EIP35,000 and not less than EIP28,000 for delivery to Dublin. Delivery was expected by August 1947. However with the railway supply industry still under government direction, a shortage of draughtsman within the industry, a shortage of raw materials and a burgeoning demand for new railway equipment the expected delivery date was not going to be met. It was also learned that construction would be transferred to Hunslet, with the power units to be supplied by Mirrlees with Brown-Boveri electrical equipment.

The cost for the two locomotives had now risen to EIP104,000, the low axle loading specified required three axle bogies necessitating a longer frame and therefore more materials required. Additionally the electrical equipment was now being sourced from the continent, no doubt with increased costs, delivery was now anticipated for September 1948. Clearly the CIE were not willing to accept these delays and so employed resources within their own company to build not only the two mixed traffic locomotives but also five shunting locomotives.

Thus it was left to the CIE's Inchicore drawing office to prepare a number of general drawings under the leadership of J J Johnson, Assistant Mechanical Engineer. One such drawing featured an American style single cab Bo-Bo unit of 915hp weighing 70tons. A six cylinder power unit was specified, though no maker was indicated, however four Metrovick Type 271 traction motors were specified in the drawings.

Eventually the design that was approved was that which became CIE 1100 & 1100.

![]()

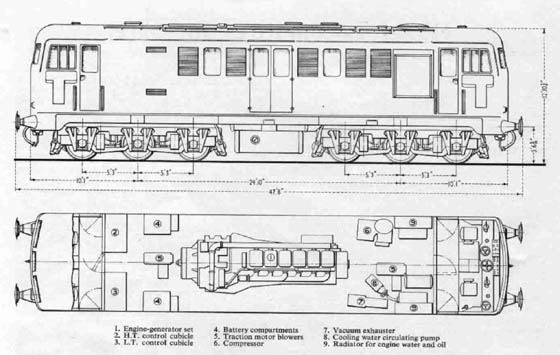

Built CIE Inchicore 1950 & 1951

Sulzer 6LDA28 915hp at 750rpm (one hour) & 815hp at 700rpm (continuous), uprated in 1956 to 960hp.

Cylinders: 11in by 14in

One Metropolitan Vickers eight pole main generator, self-ventilated, self-excited separately excited, with decompounding series field windings (for starting the engine by motoring the generator). Main generator rating was 1270amps 390volts at 700rpm one hour and 1100amps 475volts at 700rpm continuous.

One auxiliary generator of 110volt six pole type rated at 50kw at 550rpm, self excited.

Four Metrovick MV157 traction motors, rated 290amps 475volts 224hp continuous and 350amps 360volts one hour

Bo-Bo wheel arrangement, wheel diameter 44 inches, gear ratio 16:65.

Maximum Tractive Effort: 46,000lb

Weight: 80 tons

Maximum Speed: 55mph

Brakes: Westinghouse air brake system for the locomotive, vacuum for the train brakes.

Fuel capacity: 420 gallons

Cooling water capacity: 165 gallons

Multiple unit working and steam generator equipped, later isolated/removed.

Although the orders were placed in 1946 a shortage of materials forced work to proceed slowly such that the first locomotive, 1100, was not available for trials until January 1950. The trials were successful, meeting the specified criteria and on several occasions outperforming that which had been expected. On June 13th 1950 a non-stop run from Dublin to Cork with 350 tons (eleven bogie coaches and a van) was run in four hours ten minutes at an average speed of 40.3mph. A further test train of 440 tons revealed an average fuel consumption of .0016 gallons per gross ton/mile, or approximately 116 gallons of fuel used between Dublin and Cork on such a working.

Classified 'C2a' 1100 was painted green passenger locomotive livery and entered service in April 1950. Workings included the afternoon Amiens Street - Cork portion of the Belfast - Cork Enterprise, returning to Dublin the next day on an afternoon working, speeds of upto 60mph were required for this job. Other top link duties over this route included the evening down Cork Mail, returning north with the next day's tough 11.55am passenger and a morning down working followed by an evening Perishables job.

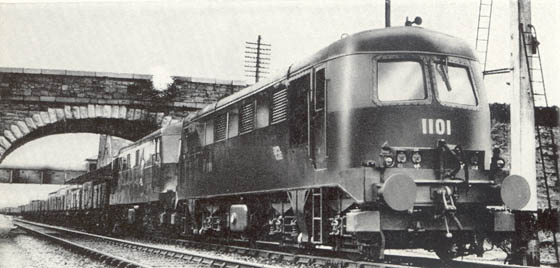

The second locomotive, 1101, was not completed until October 1951 and was similar to 1100 apart from the bogies. 1100 was fitted with two non-bolster type bogies, of a riveted construction, the Hoffman roller bearing axleboxes supported by seperate overhung fourteen leaf laminated springs with adjustable hangers, auxiliary helical springs were also provided. 1101 was fitted with a pivotal swing link, though this seemed to do little to improve the notoriously poor ride of both these machines.

Although the locomotives were equipped to work in multiple with just one driver this appears to have been a rare event. During May 1955 both locomotives were used with a test train totalling 700 tons. In addition to the rough ride encountered by the train crews the cabs themselves were spartan and uncomfortable to say the least. Cold and cramped seem to be the best adjectives to describe the conditions in the cab, layout of the equipment was poor and little comfort could be obtained from either of the tip-up seats that were bolted to the cab bulkhead.

Like the LMS twins 10000/01 on British Railways once deliveries took place of newer diesel locomotives and railcars the duties performed by 1100/1101 changed. They were removed from the top link passenger workings, frequently being allocated to freight workings and other lesser duties. The introduction of steam heating vans saw the train heating boilers removed, as was the little used multiple unit operation equipment. Not all the news was bad, the engines were uprated to 960hp, similar to those fitted in the B101 class and in 1957 they were renumbered B113/114. They both received a fresh coat of green paint, B113 being painted early in 1958 for the occasion of the visit of the Institute of Locomotive Engineers to Inchicore Workshops in May 1958, where much rolling stock was exhibited. During 1960 the Northey Boyce rotary exhausters were replaced by Westinghouse exhausters, similar to those fitted to the Crossley A class.

By the late 1960's the locomotives were confined mostly to local work around Dublin, only occasionally making it out onto the main line for longer journeys. The locomotives had throughout their careers been plagued by an unexpected, intermittent loss of brakes whilst on the road. Much study and the use of engineers travelling on the locomotives failed to resolve the issue, frequently the problem would correct itself within minutes. On a number of occasions the runaways were stopped by the application of the handbrakes whilst at other times quick thinking railwaymen diverted the runaways out of harms way allowing gravity and handbrakes to bring the trains to an orderly halt without damage. One such event was recorded on August 28th 1971 when B114 ran away with a heavy goods train whilst running down the 1 in 84 'Gullet'. The driver, not surprisingly jumped from the locomotive, fortunately the signalmen was able to divert the runaway onto the North Wall branch where a rising gradient finally stopped the train without damage. B113 was also involved in a similar runaway whilst working a freight from North Wall. Whilst securing the wagon brakes at Cabra the locomotive lost all air and ran away down the 1 in 65 towards Kingsbridge goods yard, only the diversion of the train into an empty loop prevented a collision.

Both locomotives remained out of traffic for some considerable time, but during October 1974 B113 received modifications to the braking system, involving the fitting of chokes on the air pipes leading to the brake cylinders. B114 was so treated in December 1974 but never returned to traffic. Although B113 had returned to traffic its time in service was brief, on January 7th 1975 it ran light to Kingsbridge to work the repairs train to Inchicore, after this duty it was shut down ending its service career with the CIE.

| CIE Locomotives 113 - 114 (formerly 1100 - 1101 until 1957) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number | Date to Traffic | Date taken out of Service | Scrapped |

| 113 | April 1950 | January 7th 1975 (A) | Preserved | 114 | October 1951 | August 30th 1971(A) | March 1995 at Inchicore |

Notes

(A) Out of service from January 1972 to October 1974 for brake modifications.

(B) Out of Service August 1971 to December 1974 for brake modifications, which were completed but locomotive never returned to service.

Tabular information based on data provided by Martin Baumann.

During 2011 B113 was presented by the CIE to the Ulster Folk & Transport Museum, Whitehead, with movement by road taking place on or about May 12th 2011, during the early morning hours. On January 22nd 2012 B113 moved from Whitehead to its final resting place at the Rail Gallery in Cultra.

B113 is the oldest main line diesel preseved in Ireland or Great Britain. At the time of the move to UFTM the engine, generator and traction motors were present, the turbo charger, along with many part of the control gear and other miscellaneous items were missing. The condition of the brakes, never a great item when in service, would be of considerable concern. The cab interiors are cramped with wooden floor boards. The driving position featured large Continental style throttles like a steering wheel. The driver's seat was of the fold-up type mounted on the bulkhead. The driver's desk was of considerable depth for the amount of controls it contained, with no space for leg-room underneath so the driver would have to lean forward awkwardly to handle the controls whilst keeping a foot on the vigilance pedal. The depth of the driving desk left the cab very cramped. The layout and appearance of the throttle, brake levers, etc. appeared similar to those of the B101 Sulzers and Metro-Vicks.

![]()

Metropolitan-Vickers – The CIE Prototypes 1100 & 1101

Thoughts from Steve Palmano

The CIE prototype pair of 1950-51 provided Metropolitan Vickers (MV) with an entry into the mainline diesel-electric locomotive business. It was already an established supplier of electric traction equipment, including mainline locomotives, as well as heavy electrical engineering equipment generally. To some extent its association with Sulzer shaped the approach it took to certain aspects of diesel-electric locomotive design.

As a first step in dieselization, in 1946 CIE, Ireland ordered a pair of 915 hp prototype mixed traffic locomotives. These would be built by CIE at its Inchicore works, and would have Sulzer 6LDA28 engines and Metropolitan Vickers (MV) electrical equipment.

It is understood that the decision by CIE to home-build these locomotives arose partly because the UK industry was not yet in a position to design and build against a reasonable timeline. At that time the American industry was yet to offer export-oriented locomotives suitable for lighter track and restricted loading gauges. (The American line-service diesel export model era could be said to have started with the first General Electric shovel-nose design for LGB, Argentina, in 1949.)

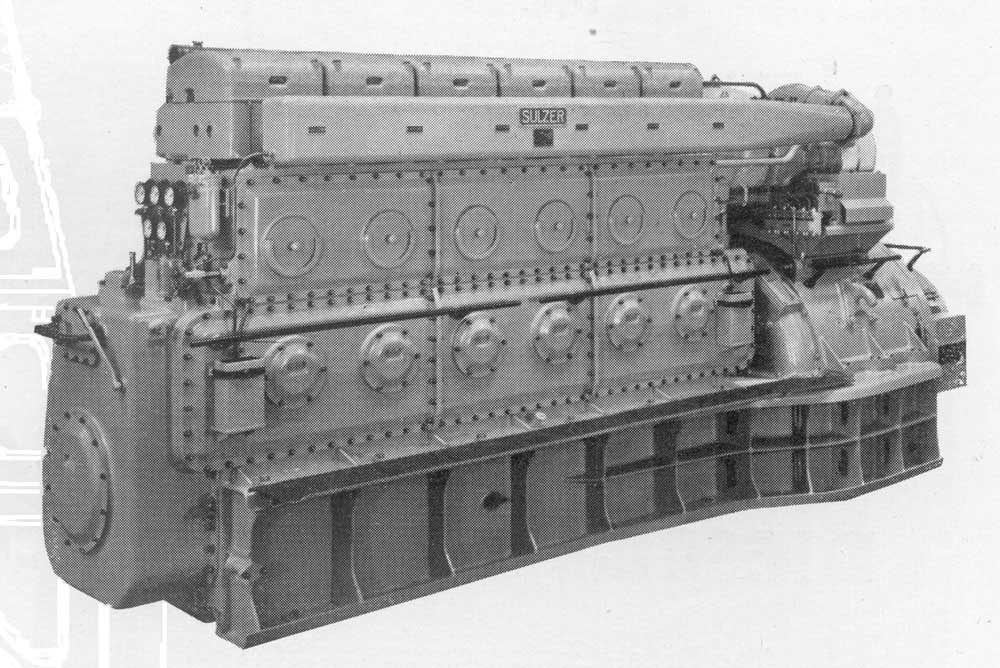

How CIE went about choosing an engine is unknown. However, at the time, Sulzer would have presented itself as a suitable and experienced supplier for line-service locomotives in the power range required, so was a logical choice. On the other hand, none of the British engine builders had significant relevant experience. Sulzer would also have been able to provide guidance on aspects of the mechanical design if required. In particular it liked to have a “clean” engine room layout, with good access to the engine topworks. The two Sulzer engines involved were built in Switzerland (Winterthur), although at the time, Sulzer was in the process of arranging licensed building by Vickers at Barrow-in-Furness.

Similarly, how MV was chosen as the electrical equipment supplier is unknown. Sulzer worked with a wide range of electrical equipment suppliers. It required that they meet its own specifications in respect of the control system and resultant performance characteristics, but reasonable latitude was allowed as to how compliance was obtained. In this case, MV acted as a subcontractor to Sulzer.

The second step of CIE’s initial dieselization plan involved the building of six 1800 hp twin-engined fast passenger locomotives, each to be powered by two of the same Sulzer engines as used in the prototypes. The engines were ordered circa 1948, and were to be the first to be licence-built by Vickers in the UK. Subsequently, CIE cancelled this plan, and the twin-engined locomotives were not built. However, as the 12 engines for them were already in construction, CIE was obliged to take them into store whilst it found an alternative disposition. Eventually this turned out to be the 12 B class locomotives built by BRCW.

Thus, both Sulzer and MV had obtained entry to the CIE business. In the MV case, that turned out to be bountiful, as it subsequently sold another 12 electrical equipment sets and 94 complete locomotives to CIE. It was less productive for Sulzer though, who sold only the 14 engines. This may have been simply circumstantial, in that the 94 complete locomotives were designed and built after MV had aligned itself with Crossley as its engine supplier. The Crossley engines were likely lower cost than comparable Sulzer engines, as the latter tended to be at the high end of the price range for a given output bracket. Possibly too CIE was unhappy that it had to accept the 12 Sulzer engines for which it had no immediate use for.

Turning to the two CIE prototypes themselves, they were largely conventional, double end cab units on Bo-Bo running gear. The first, #1100, was completed in 1950, and the second, #1101, in 1951.

The 6LDA28 engines provided 915 hp at 750 rev/min as a one-hour rating, and 815 hp at 700 rev/min as a continuous rating. At the time, the quoting of both one-hour and continuous ratings was typical for Sulzer, although that practice fell away during the 1950s.

During 1956, the engines were uprated to correspond with those of the BRCW B class, namely 960 hp continuous at 710 rev/min, with the one-hour rating said to be above 1000 hp. Progressive improvements to the 6LDA28 engine allowed this, and these were also applied retroactively to the prototype engines.

The MV main generator, of unknown model number, was an eight-pole machine with self, separate and series decompounding field windings, the latter also used as a starting winding. The separate field winding was energized by the auxiliary generator via both a stepped variable resistor and the load regulator rheostat. The decompounding provided generator curves that were noticeably drooped, and this did seem to be preferred by Sulzer. But it could have been an MV choice as well. Manufacturer preferences on this item varied quite considerably.

The four traction motors, of the conventional four-pole type, and connected in permanent parallel, were of the MV157 model. They had three stages of field weakening, which was controlled progressively, i.e. one motor at a time. (The latter appears to have been a Sulzer idea.) They drove 44 inch wheels via 65:15 resilient gearing, for a maximum speed of 55 mile/h.

The all-parallel traction motor connection became the MV norm. Possibly it also reflected a Sulzer preference, in that it had been used in other recent Sulzer-engined locomotives, such as the RSR, Thailand 651 (Bo-Bo) and 561 (A1A-A1A) classes, and the SBB Am4/4 class (Bo-Bo). Later, the all-parallel connection made it relatively easy for MV to build a five-motor locomotive, namely the BR Class 28.

In the DC-DC era, the virtues and vices of traction motor connections, in particular all-parallel vs series-parallel, were argued extensively by their various proponents. One claim for all-parallel was inherent greater freedom from wheelslip, and faster correction of it when it occurred. In favour of series-parallel are lower main generator maximum current, and lower traction motor voltages, with reduced tendency to flashover. More sophisticated slip control systems addressed that aspect. Insofar as both approaches were found in what were generally satisfactory locomotives, one could say that the delivered performance was more a question of good engineering than of the initial choice of connection type. Also argued was the choice between a single fixed grouping and the use of two groupings, such as series-parallel and all-parallel, with transition, manual or automatic, between them. This approach was uncommon in European practice, though.

Starting tractive effort was 46 000 lbf. This was 26% adhesion, so was likely to have been the equipment-limited number. Continuous tractive effort was 19 000 lbf at 11.5 mile/h.

The locomotive was fitted with straight air brakes, and equipped for hauling vacuum-braked trains. This was probably the modal choice for diesel (and) electric locomotives that hauled vacuum-braked trains. Such locomotives had air pressure systems anyway, and it was usually much easier to fit air brake cylinders to bogies than the much larger vacuum brake cylinders. Typical European practice was to provide for direct control of the train automatic vacuum brake, with a proportional valve to control the locomotive straight air brake. Independent control of the locomotive brake was also provided, usually with the facility for independent-release-after-automatic application, this being done electrically. Frequently. motor-driven rather than engine-driven exhausters were used, usually of the two-speed type, the higher speed being used for brake release, triggered electrically from the vacuum brake valve.

The 110 volt, 50 kW auxiliary generator was overhung from the main generator. The auxiliaries, the engine cooling fan, the air compressor, and a pair each of traction motor blowers and vacuum exhausters, were all motor-driven. This “all-electric” approach did appear to be the Sulzer preference at the time, although whether MV might have done differently absent the Sulzer influence is unknown. 110 volts for the auxiliary electrical system was probably the modal choice amongst the UK builders at the time, and later became the BR standard. Swiss practice, as reflected in some other Sulzer locomotives, was to have a higher voltage, for example 150 volts, auxiliary electrical system for engine starting and major auxiliaries, with a small motor-generator set providing 32 (or 36) volts for the control system. So, one could say that MV’s ideas probably prevailed there.

The power control system followed Sulzer’s norm at the time. It was developed (and patented) in 1939, and was first used on the RSR, Thailand 651 class Bo-Bo locomotives of 1942. It was a 10-notch stepped system. The first two steps were fixed excitation starting notches at minimum engine speed. Thereafter followed eight load control notches at progressively increased and evenly spaced engine speeds from minimum to maximum, with a corresponding progression in load settings. The 9th notch corresponded to the maximum continuous engine rating, whilst the 10th notch corresponded to the one-hour rating. The control wheel was spring load to return to notch 9 unless manually held in notch 10.

The Sulzer engine governor that was part of this control system had integral engine speed control, via a four-solenoid mechanism, and an integral load control pilot valve. That might have been an industry first. For example, well-known US governor specialist Woodward did not reach that level of integration until its “New SI” model of c.1945. (As far as I know it was first deployed on the EMD F3 model,) Separate to, but linked with this Sulzer governing system was an overriding mechanism that limited the amount of fuel that could be injected in situations where the inlet manifold pressure was lower than normal because of turbocharger run-up delay or other causes. Sulzer later incorporated this facility within the governor. The 1939 Sulzer governor design also had provision for two load set points -electrically controlled - for each engine speed, thus doubling the available load control notches from eight to 16. As far as I know, this was not used in practice by Sulzer. However, the same function was available in the Regulateurs 1100 series governor of 1963. I think it was used in the BR HST powercars, to allow whichever was supplying hotel power to have power control notches 1 and 2 both at 2nd engine speed, instead of at 1st and 2nd engine speeds respectively as was otherwise the case. In those days one could say that Sulzer was “somewhat ahead of the curve”. The CIE prototype pair were fitted for MU, although in practice they could work only with each other.

MV adopted a master controller that was similar, but not identical to that recently used by Sulzer. The latter had used a three-shaft unit. The power control shaft was central. To one side was the reverser shaft, with removable handle, and to the other side the engine start/stop shaft. MV changed the relative positioning, with the power control shaft to one side, the engine start shaft in the middle, and the reverser at the other end. Also, the engine stop function was done by a push button, rather than by the engine start shaft. Like Sulzer, MV used a handwheel rather than a handle to rotate the power control shaft. This set the pattern for subsequent MV diesel-electric locomotives in the pre-AEI era. These all had 10-notch control (although sometimes with different notch sequences) and mostly had three-shaft master controllers. The BR Class 28 conformed to the BR pattern by having a two-shaft master controller, but alone amongst the Pilot Plan locomotives, it had a handwheel rather than a handle for power control.

The first prototype, #1100 of 1950, had rigid-bolster bogies of conventional rivetted plate-frame construction. Perhaps unsurprisingly, the ride quality was said to be not very good. But MV influence was seen in respect of the running gear for the second prototype, #1101 of 1951. Here the bogies used the MV bolsterless outside swing link system, albeit apparently applied to the basic plate frame design. This used a lever system to create a virtual centre. Nonetheless, it evidently made little difference to ride quality.

The outside swing link arrangement originated with the Co bogie that MV had designed for use under the gas turbine-electric prototype ordered by the former Great Western Railway in 1946, but delivered as BR #18100 in 1951. One objective was to have a lateral motion Co bogie that did not incur the ride height penalty of a “conventional” design with a bolster arched over the centre axle. BR HQ (then the Railway Executive) expressed reservations about this design in 1948, and suggested that the Ivatt/LMS Co bogie be used, as developed for the LMS/BR prototypes #10000, 10001. That achieved a lower ride height through the use of a slim, non-load bearing bolster. Evidently MV and/or the BR Western Region (WR) resisted that idea, and it was not implemented. The BR HQ reservations turned out to be justified; the bogie was not a good performer in either the Co form under BR #18100 or in Bo form under CIE #1101. In Bo form, the same bogie design was used under the Bo-Bo 3 kV DC electric locomotives that MV built for two Brasilian systems, RMV and RVPSC, ordered in 1949 and delivered 1953-54. In that case though the bogie design looked to be fully integrated.

The flat-fronted body style was more likely a CIE choice, although it conformed to established Sulzer practice. Early British export practice favoured the nose-end style for cab units, this being used by English Electric, Brush, and BRCW.

The pair were fitted with train heating boilers, at the time quite common practice for diesel locomotives intended to haul steam-heated passenger consists. Later, the CIE determined that the use of separate steam heating cars was a better option than equipping locomotives with boilers, so subsequent diesel locomotive classes lacked this feature. And once the steam heating cars were available, the boilers were removed from the prototypes. That was another debate of the time – whether train heating boilers should be in the locomotives or in ad hoc cars, although this was overshadowed by the bigger issue as to how quickly passenger cars should be fitted with electric heating, thus obviating the need for boilers altogether.

In 1957, the two prototypes were reclassified into the B class group, and renumbered as 113 and 114 respectively. They operated into the first half of the 1970s, so had reasonably long lives.

From an MV perspective, its early association with Sulzer clearly shaped its approach to diesel-electric locomotive design, although it certainly entered the business with full capability to produce the basic electrical equipment. It was also developing its own ideas in respect of mechanical design, as shown by the bogie secondary suspension system applied to the second CIE prototype, #1101.

![]()

During 1948 the CIE placed an order for six 1,800bhp express locomotives for the Dublin - Cork line. Shortly afterwards a change in the Irish government led to attempts to cancel the order. Vickers Armstrong were already well on their way to completing the power units - much debate continued behind the scenes with all parties involved. Its seems that the threat of a substantial cancellation penalty (varying between EIP60,000 & EIP100,000 depending on who your source was) led to the order being changed. Now it would be for twelve mixed-traffic locomotives to incorporate the already completed equipment, of a general purpose design to be constructed by the Birmingham Railway Carriage & Wagon Co. Ltd. An axle loading of just fifteen tons would allow greater route availability for these locomotives. BRCW Builder's numbers were DEL20 - DEL31.

The power units were the first Sulzer diesel engines, for railway traction, to be constructed at the Barrow works of Vickers-Armstrongs Ltd. The 6LDA28 engine was now rated at 960bhp at 710rpm for the continuous rating & 1,000bhp for the one hour rating. Cylinder size was 11 inches by 14.2 inches, the exhaust gas turbo charger was of Sulzer make. The main & auxiliary generator were provided by Metropolitan Vickers, a common welded steel subframe, forming part of the crankcase structure, supported the engine & generators.

They were 47ft 8in long and 12ft 11in high, top speed was 75 mph with a service weight of 75 tons, the maximum axle loading was 14.75 tons. Adhesion weight was about 57 tons with a maximum starting tractive effort of 41,800lb, the continuous rating being 16,900lb at 16mph. This rating would allow a 300 ton train to be hauled between Dublin & Cork without banking assistance on the 1 in 60 gradient near Cork. Two three axles bogies, configured A1A-A1A, supported the locomotive. These were of the modified Pennsylvania swing bolster type, similar to those fitted to the BRCW built Commonwealth Railways of Australia. Wheel diameter was 37.5in, bogie wheel base 10ft 6in, bogie pivot pitch was 24ft 10in. Each bogie frame is an integral welded steel structure in regard to the main longitudinal and crss member, but separate axle box guide plates were secured by driven bolts. The bolster structure is also welded, carrying a flat pivot and side bearers. Swing links are on knife edges, the side swing is stabilised by hydraulic stabilisers. The complete suspension is in the form of nests of helical springs between each compensating beam and the bogie frame, supplemented by hydraulic shock observers.

A stylised view of B101 on a passenger train, taken from an AEI brochure from the late 1960's.

One piece disc wheels are used, Timken roller bearing boxes support the axles. Braking is of the Westinghouse straight air type, though the train brakes are vacuum only.

The superstructure is full width with a cab at each end. Cab side recesses provide accomodation for tablet catcher equipment. Double doors in the center of each side give access to the engine room. All the auxiliaries are electrically driven by individual motors, all located on the engine room floor. These include a reciprocating compressor, reciprocating exhauster, cooling water pump and two traction motor blowers. Batteries are also located in the engine room. A 670 gallon fuel tank is underframe mounted between the bogies. The main water tanks are located beneath each radiator, fuel & water header tanks are located in the roof. A large removeable roof panel permits the lifting of the complete engine/generator set for maintenance/overhaul.

After the usual trials and testing the aluminium and silver liveried locomotives were used on passenger & freight workings over the southern section. They were quickly liked by the crews, giving a good ride, with spacious and comfortable cabs when compared to 1100/1101, and proved more reliable than the Crossleys. They became fixtures on the Mallow - Waterford - Tralee line and were regulars on the the line to Limerick & Tralee. They were able to keep time even on the heavier workings and were frequently recorded at sppeds in excess of 70mph.

The class would remain intact to the end - their were no premature withdrawals due to accident damage, however there were a number of near misses. Perhaps the most serious incident involved B101 working the 03.50am goods ex-Kingsbridge on March 29th 1959. At Hybla Bridge, near Monasterevan a length of rail had been removed by railway staff without providing protection to the trains. B101 and its train were approaching at about 45mph and were unable to stop before running over the section of line with the rail removed. The locomotive fortunately remained upright, the leading fourteen wagons containing weedkiller chemicals caught fire, blocking both lines. Three breakdown cranes (from Inchicore, Broadstone & Athlone) were needed to clear the wreckage. B101 somehow remained upright in the derailment, preventing major damage to the locomotive, its driver was not seriously injured. Five months later on August 9th 1959 B108 collided with its own train at Limerick Junction whilst running round, minor damage was sustained and four passengers were taken to the hospital.

The B101 class were also to be found working many 'last trains' as much of the branch network underwent a severe rationalisation in the 1960's. On January 1st 1963 B101 worked the last regular train on the Castlecomer branch. A month later on February 2nd B109 worked the last regular Youghal passenger. On this same date an un-identified B101 class worked the last Foynes passenger/mixed. The last freight on the Thurles-Clonmel line was hauled by B105 on March 25th 1967 and B106 worked the last train, a weedsprayer, over the Burma Road.

The arrival of the 181 Class saw the Sulzers taken off their more important duties, being relegated to goods, permanent way and pilot duties. By the early 1970's the writing was on the wall for them, although the first to be sidelined had been B111 in 1969 after sustaining fire damage. B102 suffered a near miss on August 13th 1970 when it went through the stop-block at Liffey Bridge, Heuston and nearly ended up in the river. On January 10th 1973 a fire in a traction motor on B108 spread to the body sidelining the locomotive, it would never run again. During February 1974 B105 was received at Inchicore with serious cab damage, surprisingly repairs were effected and the locomotive returned to traffic, becoming one of the last four in service. In June of 1974 B106 was recieved for major repairs at Inchicore, it was outshopped in February 1975, the last of the class to recieve heavy repairs. A proposal to re-engine them, along the lines of the A & C class was rejected, the 071 class was purchased instead.

Four soldiered on until November 1977 when three were taken out of service, leaving B106 as the last in service. At the end of January 1978 B106 was working the Inchicore repairs train. The locomotive was specially cleaned up and serviced to work the Irish Railway Record Society's 'Farewell to the Sulzers' tour on February 4th 1978 from Dublin (Connolly) to Bray and back. A simple electrical fault the following Monday proved to be the end for B106. The last job worked was the Heuston - North Wall transfer job, after being failed the locomotive was towed back to Inchicore and that was the end of the Sulzers in revenue earning service in Ireland.

During June 1980 the B101 class came together for one last time as they were shunted onto the Workman's Siding at Inchicore Works to await their fate - which is tabulated in the list below.

| CIE Locomotives 101 - 112 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number | Date to Traffic | Date taken out of Service | Withdrawn | Scrapped |

| 101 | April 9th 1956 | May 6th 1974 | April 1984 | March 1987 | 102 | August 4th 1956 | October 3rd 1974 | April 1984 | March 1987 | 103 | August 13th 1956 | November 17th 1977 | April 1984 | Preserved | 104 | August 30th 1956 | July 15th 1974 | April 1984 | January 1987 | 105 | September 17th 1956 | November 22nd 1977 | April 1984 | March 1987 | 106 | November 8th 1956 | February 7th 1978 | April 1984 | December 1986 | 107 | February 25th 1957 | May 25th 1977 | April 1984 | February 1987 | 108 | April 16th 1957 | January 10th 1973 | April 1984 | January 1987 | 109 | June 19th 1957 | January 20th 1975 | April 1984 | February 1987 | 110 | July 13th 1957 | November 15th 1977 | April 1984 | April 1987 | 111 | October 15th 1957 | May 13th 1969 | April 1984 | April 1987 | 112 | December 23rd 1957 | July 27th 1973 | April 1984 | February 1987 |

All locomotives apart from 103 were scrapped at North Wall Point Yard.

![]()

Liveries

Throughout their lives the locomotives carried a variety of liveries, not all locomotives carried all the variations.

From the factory they were turned out in a silver livery, following this a pale green livery, some carried a light green pinstrip around the entire locomotive.

Next came the rather austere, somber looking black livery with a white stripe at roof level. This livery was later amended to include an orange band above the frame level with the band curving round to include the lower cab front. All locomotives carried the first three liveries.

The final livery saw the black and the orange reversed, with orange now predominant with a black waist level band applied to the sides and expanding on each cabfront. B105, 108, 109, 111 were stopped before receiving this livery.

![]()

B103 in preservation

During 1977 B103 was earmarked for preservation by Westrail. The option was not immediately taken up, consequently B103 remained in open storage from 1977 to at least 2003, allowing for a gradual deterioration of much of the body work and the internal components. Along with the other members of the Class B103 was stored alongside the up main line at Inchicore. After the other members were scrapped during 1986/87 B103 moved into Inchicore Works for further storage. B103 would be sold to the Irish Traction Group late in April 1993 after Westrial released themselves from their option on the locomotive. B103 departed Inchicore on July 1st 1993, travelling via Kildare and Limerick Junctioon, arriving at Carrick-On-Suir on August 14th 1993.

Internally B103 is substantially complete. Two rotors are missing from the load regulator but replacements were obtained ex B114. The traction motor cables are still attached but the two traction motor blowers are missing, though replacements are advised as being easily obtainable. The rocker covers are missing which has allowed water to leak into the engine, the extent of the damage so caused is not yet known. Being one of the earliest 6LDA28's in the United Kingdom & Ireland the rocker covers are not standard, all the threads on the engine are Whitworth, creating a problem since there were fewer imperial threaded engines produced and therefore less spares available. Being aluminium the rocker covers were removed at an early stage. Attempts to use covers from a BR Class 47 failed, these have additional cut outs for pipes not found on B103.

Half of the turbo charger is missing, but one was retrieved from B114 before it was broken up. A vacuum brake handle is missing as are two of the removeable loco air brake handles. Nearly all thirty six radiator elements are missing, though an almost full replacement set is to hand acquired from a 'C' Class loco scrapped at Inchicore.

Late in November 2003 several hardy Irish Traction Group volunteers were able to sheet B103 in plastic providing a little protection from the elements.

(Written November 2003)

During 2004 asbestos discovered in the cab doors and cab/engine room bulkheads was professionally removed.

By May 2010 a protective cladding had been built around the locomotive to provide protection from the elements.

![]()

The following notes and logs have been provided by Dermot Mansfield to add a little more detail about the operation of the CIE's Sulzer powered locomotives. These notes hopefully add to the existing information above, although at this time these notes do make some corrections to the original text above - I have not had chance to incorporate these corrections yet.

1100 & 1101

The early Sulzers, 1100 & 1101 (1950/51) never worked on the more demanding passenger duties, which required the steam 4-6-0s of classes 400 and 500 (2 cyl) and 800 (3-cyl). And certainly they never headed the Dublin to Cork extension of the Belfast to Dublin Enterprise express, which ran from 1950 to 1953. As mentioned in driver Dan Renehan’s article on the Sulzers in the Journal of the Irish Railway Record Society (Oct 1981), they could be found working the heavy 20.00 down Cork Night Mail and the following day’s 11.55 up passenger from Cork, as well at the 08.00 down and the 20.30 up Night Mail. Occasionally they were found on the Sunday down and up all-stations stopping trains.

The notes below refer to the Dublin-Cork double track mainline, 165.3 miles long, and which, although well engineered, in the post-war period had an overall 70 mph speed limit imposed. There were a few intervening lower limits, such as 50mph through Portarlington and Mallow stations. I might add that of course the Irish gauge was wider than that in Britain, at 5ft 3in.

Below are details from a log, copied a long time ago from a notebook of Leslie Hyland, of a run with 1101 on the up 11.50 ex Cork Sunday train, from Limerick Junction onwards, timed on February 6th 1955. The load was 7 bogie coaches, 212 tons tare. (Unfortunately I only took down details of the main stops, and not of the stops at smaller intervening stations).

| Location | Mileage | Time | Notes |

| Limerick Junction | 0.00 | 14.19 | departure 4 min late | Dundrum | - | - | - | Goold's Cross | - | - | - | Thurles (arr) | 20.4 | 14.55 | arrival 5 min late | Thurles (dep) | - | 15.01 | departure 6 min late | Templemore | - | - | - | Lisduff | - | - | - | Ballybrophy (arr) | 40.3 | 15.34 | arrival 8 min late | Ballybrophy (dep) | - | 15.38 | departure 9 min late | Mountrath | - | - | - | Portlaoise (arr) | 56.1 | 16.02 | arrival 10 min late | Portlaoise (dep) | - | 16.03 | departure 10 min late | Portarlington (arr) | 65.4 | 16.16 | arrival 11 min late | Portarlington (dep) | - | 16.17 | departure 7 min late | Monasterevin | - | - | - | Kildare | - | - | - | Newbridge | - | - | - | Sallins | - | - | - | Dublin Kingsbridge | 107.1 | 17.22 | arrival 7 min late |

Notes:

Stops were made at Dundrum and Goold’s Cross but the times were not recorded. The speed did not exceed 50mph between Limerick Junction and Thurles. Between Thurles and Ballybrophy stops were made at Templemore and Lisduff, speeds on this section had been 50mph before Templemore, and 53.5mph before Ballybrophy. Beyond Ballybrophy speed reached 59 mph down the 1 in 128 bank before the stop was made at Mountrath, 53 mph was attained after this stop. Between Portlaoise and Portarlington a maximum of 57mph was achieved on the slight downgrades.

At Portarlington the lateness was cut to 7 minutes, the 5 minutes allowed here for watering the steam locomotives was cut to 1 minute by the presence of the diesel. Stops followed at Monasterevin, Kildare, Newbridge, and Sallins, before terminating at Dublin Kingsbridge, now 7 minutes late. After the Sallins stop, and on a slightly favourable incline (1 in 450), speed reached 60 mph, and remained in the upper 50’s thereafter for some miles.

I don’t know whether this was an average performance, or one below normal. But it does show how limited these locomotivess were on passenger work. The steam engines, between stations on the Sunday trains, would often gallop up to about 60-65 mph, and thus keep time. 1100 & 1101 were out of their league! Later, when they were numbered B113 & B114, I had a number of runs myself behind them working the 12.40 ex Dublin light passenger, a weekday train, stopping also at all stations. Even though they had been theoretically uprated at this point from 915hp to 960hp, they were still sluggish. I think they were a little more adequate on goods turns, which along with short freight transfers, and shunting, was their lot towards the end of their time.

B101 Class

The twelve class B101 Sulzers (1956-57) were fine machines and much admired. Their 6LDA28 units, incidentally, had been constructed after an order had been placed in 1948 — but later cancelled — for six powerful express mainline locomotives, which would have had two units in each locomotive. Especially, I remember them working between Dublin and Cork on the three-hour expresses, which, with or without an intervening stop at Limerick Junction, required an overall 55 mph average start-to-stop. They shared this duty with the AEC railcar sets and the A Class 1,200hp Crossley powered locomotive-hauled trains. I never saw them on the heaviest trains on this route, namely the 10.45 down, the 11.30 up and the 15.35 up Day Mail, all of which were solely the province of the A Class. But they could be found on the other services mentioned above in connection with No. 1100 & 1101, although again I never saw one on the Sunday trains. They sometimes worked Dublin to Limerick, which service branched off the mainline at Ballybrophy, and went onto Limerick via Roscrea and Nenagh. Occasionally they were seen on Dublin to Tralee trains, branching off at Mallow and going via Killarney to Tralee, at 207 miles the longest route in Ireland.

For me, living beside Portarlington station, they were most regularly to be seen on the Dublin to Waterford passenger trains via Portlaoise, Abbeyleix and Kilkenny. Again they shared duties here with the AEC railcars and the A Class Crossleys. They also worked the other route to Waterford, from Cherryville Junction south of Kildare, through Carlow and into Kilkenny. Also, as Dan Renehan states, “they made the Mallow-Waterford-Rosslare line their own”. This was a twisting and steeply graded line, over which the Cork to Rosslare Express had run since 1907, and which before the arrival of the Sulzers had been a favourite route of the SR type Maunsell moguls (known in Ireland as “Woolwiches”). And one other line was also frequented by the Sulzers, that between Waterford and Limerick, via Clonmel and Limerick Junction. They were also to be seen regularly on goods trains of various kinds.

Let me set out as best I can the log of a run with B103 on the 14.25 ex Dublin Kingsbridge three-hour express to Cork, timed on 22nd November 1956 by the late R.N. Clements. The load was a light winter one of five bogie coaches, a 4-wheel luggage van and a 4-wheel heating van, weighing 174 tons tare, and I suppose 190 loaded. This train had a scheduled intervening stop at Limerick Junction of 3 minutes (but an extra 2 minutes was required here, as trains in both directions had to reverse back to the platform after an initial stop on the running lines). As will be seen, there was also on this occasion a short out-of-course stop at Ballybrophy.

| Miles | Location | Time (Min/Sec) | Speed (MPH) |

| 0.0 | Dublin Kingsbridge | 0.00 | _ | 4.4 | Clondalkin | 8.23 | 41 | 17.9 | Sallins | 22.08 | 65/56 | 25.5 | Newbridge | 29.28 | 63 | 27.7 | Curragh Summit | 31.37 | 53 min | 30.0 | Kildare | 34.17 | 57 | 32.4 | Cherryville Jct | 36.34 | 69 | 36.6 | Monasterevin | 40.16 | 72 | 41.7 | Portarlington | 45.40 | below 50: signal slowing | 50.9 | Portlaoise | 55.55 | 62/53/57 | 59.4 | Mountrath | 64.15 | 68 max | 65.0 | Post 65 | 69.59 | 47 min | 66.6 | Ballybrophy | 72.18 | out of course stop | 72.0 | 31 start | - | - | 72.4 | Lisduff | 80.11 | 60/56 | 82.1 | Templemore | 86.00 | 67 | 86.5 | Thurles | 95.23 | two p.w. slacks | 94.8 | Goold's Cross | 103.41 | 70/58 | 99.3 | Dundrum | 107.55 | 64/58/63 | 107.0 | Limerick Jct | 115.48 | scheduled stop |

There is a sharp climb out of Kingsbridge, including 1 in 84 up to Inchicore Engineering Works, and 1 in 100/138 thereafter. Hence the slow time to Clondalkin. Later, the line climbs at 1 in 172 from Newbridge to the Curragh, and falls at 1 in 180 from Kildare towards Monasterevin. The next major rise is at 1 in 128 for nearly 3 miles to Post 65.

Net time for the first part of this run was 110.30, scheduled time was 117.00 minutes.

| Miles | Location | Time (Min/Sec) | Speed (MPH) |

| 0.0 | Limerick Jct | 0.00 | - | 2.8 | Post 109.5 | 4.55 | 43 | 6.6 | Emly | 9.14 | 66 | 10.1 | Knocklong | 13.24 | 67 | 17.2 | Kilmallock | 18.55 | 63/70 | 22.3 | Charleville | 23.30 | 55 min | 30.3 | Buttevant | 30.57 | 72 | 33.1 | Post 140 | 33.39 | 57 min | 37.6 | Mallow | 39.00 | 69/56 | 41.1 | Mourne Abbey | 42.22 | 47 sustained | 44.6 | Post 151.5 | 46.51 | 48 | 47.5 | Rathduff | 49.59 | 62 | 52.6 | Blarney | 54.42 | 65 | 54.6 | Rathpeacon | 56.44 | brakes | 58.4 | Cork | 62.48 | scheduled stop |

Scheduled time for the second part of the trip was 65.00 minutes.

The climb out of Limerick Junction to Post 109.5 is at 1 in 156. Then, after rising mainly at 1 in 178/142 from Buttevant towards Post 140, there is a fall at 1 in 150 towards the Blackwater river viaduct at Mallow. There follows a long climb at 1 in 125 then at 1 in 140 up to Post 151.5, after which the line drops down towards Cork. But from Rathpeacon there is a sheer fall at 1 in 60 for two miles, and then at 1 in 64/78 through the mile long tunnel before Cork station itself. B103 did well, getting ahead of time early on, to allow for the Ballybrophy stop and the two permanent way slacks in the Thurles area. The locomotive would have been notched back considerably on some of the down grades, so as not to exceed the 70 mph limit. Obviously from the last summit, at Post 151.5, the train was running very easily, to avoid an early arrival in Cork. I would say that it would have just about managed the schedule with an extra two bogie coaches, say about 230 tons tare. But sometimes, in the down direction, the prevailing south-westerly headwinds could hold a train back on the more exposed sections of line, and therefore the B101 class could have run a little late.

By way of comparison, there is a run on the same service between Dublin and Limerick Junction with a 1,200 hp A Class locomotive published in The Railway World, February 1970. Probably timed around 1960, it features A55 with 9 coaches, weighing 250 tons tare and 270 loaded. Despite a signal stop of over a minute at Lucan, soon after Clondalkin, and permanent way slacks at Portarlington and Ballybrophy, the Crossley engined diesel brought its train into Limerick Junction a minute and a half early. From Lucan starting signal to the first stop at Limerick Junction, the 100.2 miles were run in 99 min 37 sec, or 97 minutes net.

To add an earlier steam comparison, mention can be made of a run with the Enterprise between Limerick Junction and Cork, timed in August 1953. The large 3 cyl 4-6-0 No. 802 Tailte, with a train of 235 tons tare, and 250 tons loaded, and needing to make up some lost time, covered the distance of 58.4 miles in 61 min 26 sec (68 min allowed in the working timetable, but 73 in the public one). No 802 was over 1.5 min slower to Emly than B103, but then gradually overtook the diesel. In particular it climbed the 1 in 140 past Mourne Abbey at a steady 52 mph, and then was allowed to touch 78 mph before Blarney. Interestingly, on the return journey the next day, when hauling 360 tons loaded, No. 802 ran just as well onwards from Limerick Junction, covering the 82.1 miles from Thurles to Clondalkin in 83 min 30 seconds. Allowing for a permanent way slowing before Portarlington, the net time was 82 minutes, so an even time performance over this distance. This was achieved, with the 70 mph limit scrupulously observed throughout, and even though the engine was running on reduced boiler pressure (180 lb sq in; instead of the original 225 lb).

My own closest observations of the B101 class date from the years 1959-1961, when I noted down whatever locomotives passed through Portarlington, mainly on passenger trains, and also had some runs behind them. In August 1959 a friend and myself travelled on the up morning Waterford train from Portarlington to Dublin, behind B104 hauling 7 coaches and a luggage van. This was a sharply-timed train, allowed 47 minutes for the 41.7 miles into Kingsbridge Station, an average of over 53 mph start-to-stop. We had a signal slowing on the approach to Kildare, but on the slightly favourable grades after Newbridge speed fluctuated between 60 and 70 mph. Coming back on the down evening Waterford, we had another B101 class loco (number unrecorded) hauling no less than 10 coaches and van. No doubt we lost a bit of time, but nonetheless we enjoyed every moment of the run home, especially in listening to the purposeful 4-stroke throbbing sound coming from the front. Through 1960 and the first half of 1961, my notebook records many of the class at work, usually on the Waterford trains, and loads varying between 5 to 9 bogie coaches and one or two vans. There were some sightings of them on goods trains, but not much.

Then in the Spring of 1961 the first of the General Motors 950 hp locomotives appeared, and such was their success that the B101 Sulzers tended to be relegated to more secondary work, and often on those southern lines between Waterford and Mallow and Limerick as noted above. But in July 1961 I had a lively run behind B101, south from Kilkenny towards Waterford, on a Summer-only service from Dublin via Carlow. We had only two bogie coaches and a van, and so B101 happily worked up to 65 mph soon after leaving Kilkenny, and later did 60 before Thomastown, and 63 mph before Mullinavat. Then came a sudden stop near Waterford, at Kilmacow — where our engine was removed to take the place there of a failed A class on the up main evening train to Dublin! We had to wait until another Crossley locomotive came out from Waterford to the rescue, and take us the rest of the way. B101-112 were engines of modest power. But in the Irish railway scene of the years 1957 to 1961 they were quite prominent, and at the head of important trains, alongside the sixty A class locos, and with the good AEC railcar sets also operating services. To me they were impressive-looking locos, and their 4-stroke sound was full of character. They were solid and reliable, unlike the chronically troublesome Crossley 2-stroke diesels which bore the brunt of the work at that time. And perhaps it is not too much to claim that they played an important early part in the history of Sulzer 6LDA28-powered locomotives, and which of course includes especially the later British Railways locomotives of classes 24 / 25 / 26 / 27, and some of class 33.

![]()

During December 2016 Black & White quality negatives came up for bid on ebay taken at Inchicore of 1100, B101 & B102, dated 1955 (1100) and 1956 B101 & B102), selling for respectively GBP31, GBP42 & GBP80!

![]()

Sources:

'Diesel Railway Traction' November 1956.

Journal of the Irish Railway Record Society, Vol 14, No: 86 October 1981, featuring two articles:

Sulzer Locomotives of the CIE by D Renehan & CIE - First Diesel Programme by J J Leckey.

Dermot Mansfield

Steve Palmano

Mark Kennedy

Page added May 12th 2004

Page updated April 24th 2024.