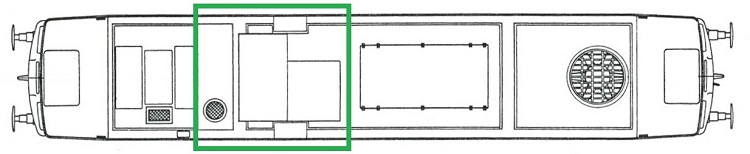

With the construction of a total of 478 Class 24 & 25 locomotives, it should be expected that changes would be made to the original designs as operational experience and specific shortcomings were identified. For the purposes of this study some improvements affected portions of the roof areas and which were not highly visible from ground or platform level. The drawing below shows the rudimentary outline of the Class 24 roof, with the area identified by the green box having undergone the most changes and variations.

The equipment layout within the locomotive body remained virtually unchanged for the 478 locomotives, thus the changes to the roof structure resulted primarily from the relocation of the engine exhaust and the winterisation of the Scottish allocated locomotives.

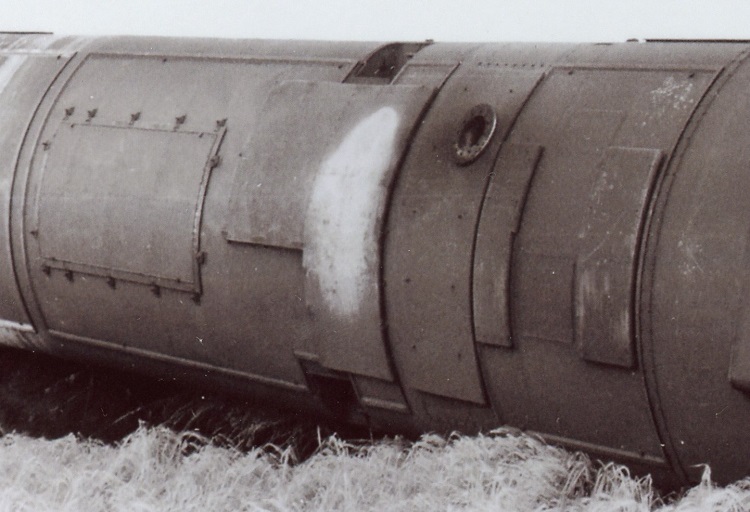

Fires in the area of the exhaust silencer led to the silencers and the associated trunking being removed with the exhaust repositioned above the engine room. The raised panel containing the circular exhaust port was also removed, with that section gaining the same flush profile to be found above parts of the engine room and the radiator space. In some cases the original circular exhaust port was temporarily left in place but capped until dealt with at a later Works visit.

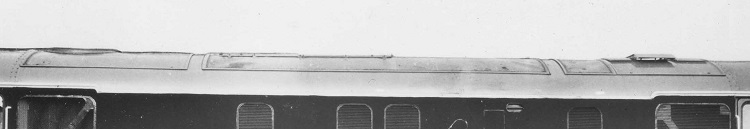

In the winterisation process for the Inverness based Type 2s, Inverurie and Glasgow removed all the raised panels, giving the roofs a much smoother appearance, similar to the Class 25/1s (D5176 - D5233 & D7568 - D7597). It is assumed that these changes occurred when the engine exhaust port was being relocated, or later if another Workshop relocated the engine exhaust port. These changes were accomplished much earlier than those locomotives being overhauled by Derby or Crewe. Glasgow would also apply these changes to any Class 24s & Class 25/0s receiving classified repairs at Glasgow.

There appears to have been several stages in the exhaust relocation process:

1) Exhaust relocation, with raised panel removed from original location.The notes below, generally based on photographic study, document changes to the roof areas.

2) Exhaust relocation, but circular exhaust port capped until dealt with at a later Works visit.

3) Exhaust relocation, with modification to the raised panels surrounding the new exhaust - several variants.

4) Exhaust relocation - the Inverurie/Glasgow variant with removal of the raised panels.

![]()

D5000 - D5150 (24001 - 24150)

When delivered new from Derby Locomotive Works D5000 & D5001 were not fitted with raised panels as found from D5002 onwards. A narrow rectangular raised panel was fitted above the electrical space, it was centered on the roof and would not be easily visible from ground level.

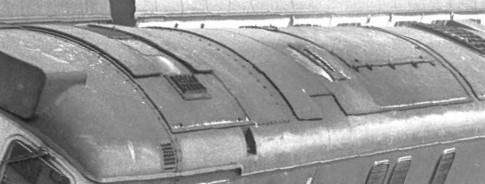

On the left side of the image, directly to the right of the No.2 end cab roof is the boiler room with its exhaust and raised panels. This roof section saw some changes, particularly for those locomotives not boiler equipped.

It is the section of roof between the boiler room and the engine room which underwent a variety of changes. The space beneath these roof sections contained the main generator, the compressor, brake gear cubicle, electrical cubicle and the ducting and silencer to support the original location of the exhaust. In the view above it comprises two raised panels with the left raised panel containing the original circular exhaust port. The 2nd panel, an 'L' shape would later contain the relocated engine exhaust and the panel itself would see changes.

It would be the relocation of the engine exhaust closer to the engine room that would bring about the various styles of roof panelling to the Class 24s.

1): original 'L' shaped raised panel retained until withdrawn.When D5176 - D5232 (25026 - 25082) and D7568 - D7597 (25218 - 25247) were built the roof design was simplified by relocating the engine exhaust and doing away with the three raised roof panels found on nearly all the Class 24s. Strangely when production of D5233 - D5299, D7500 - D7567, D7598 - D7677 (25083 - 25217 & 25248 - 25327) commenced, the exhaust location returned to the original design as applied to the Class 24s, leaving the various railway workshops at futures dates to have to relocate the exhaust to its position above the engine room.

2): no raised panels.

3): raised rectangular panel containing the engine exhaust.

4): raised narrow panel containing the engine exhaust.

The repositioning of the engine exhausts took a considerable while to accomplish, 24086 was noted at Derby Works during 1975 with the original exhaust port still in use.

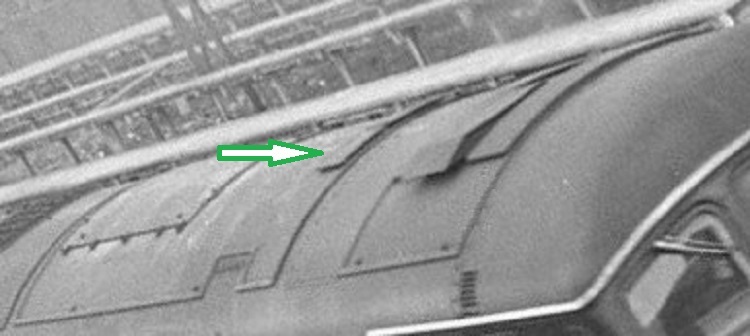

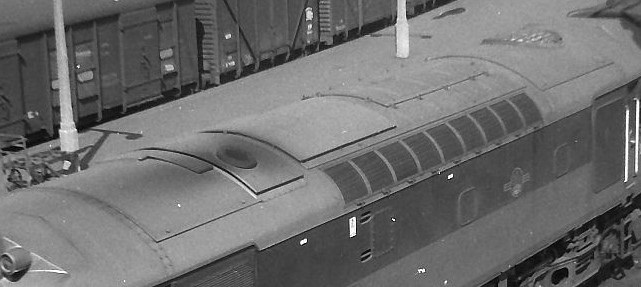

The above view of the roof of 24052 shows a typical final state. The site of the original circular exhaust has seen the raised panel removed. The repositioned exhaust sits in the raised panel above the generator / brake gear. However the original 'L' shaped raised panel has been reduced to a rectangular shape.

This view of 24081 shows the non-BIS side with the arrangement of the rectangular roof panel with exhaust, similar to the view of 24052 above but seen from the other side.

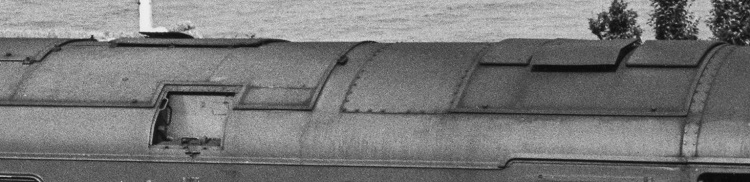

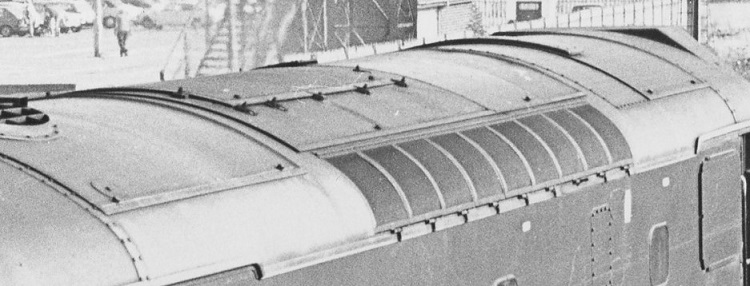

This view of 5117 shows the BIS side of a 'winterised' Class 24, with all raised roof panels removed, including the shroud above the boiler room. The engine exhaust is also of a low profile and Scottish practice for the Inverness 24s saw the cantrail level water fillers sheeted over.

This view of 24017 shows the non-BIS side of a 'winterised' Class 24, with all raised roof panels removed, including the shroud above the boiler room.

D5102 - D5111: the former Tyne Dock - Consett locomotives all ended their days on the Scottish Region, with all but 24104 visiting Glasgow Works for some sort of Classified repair - they received the winterisation improvements to the roofs. 24104 retained a raised panel around the engine exhaust, not sure if it is the 'L' shaped panel or rhe smaller rectangular version.

D5114 - D5132: the Inverness allocation all received the winterisation improvements at Glasgow or Inverurie, these occurred quite early in the careers of these locomotives.

![]()

D5151 - D5175 (25001 - 25025)

After the construction of D5000 - D5150, Darlington completed D5151 - D5175, using the body shell of the Class 24. This batch of locomotives were for freight service in the north-east and were built without train heating boilers. Because of this the boiler exhaust and the shroud in the center of the boiler room roof were not fitted - see image below.

Roof modification: original style retained until withdrawn (raised panels):

25015, 25018.

Roof modification: no raised panels:

25001, 25002, 25005, 25006, 25007, 25008, 25009, 25010, 25011, 25012, 25013, 25014, 25016, 25019, 25021, 25022, 25023, 25025.

Roof modification: raised rectangular panel containing the engine exhaust:

25003.

Roof modification: raised narrow panel containing the engine exhaust.

None identified with this modification.

Requiring further research: 25004, 25017, 25020, 25024.

Cantrail level water fillers sheeted over: 25006 (unique to the Class 25/0s).

![]()

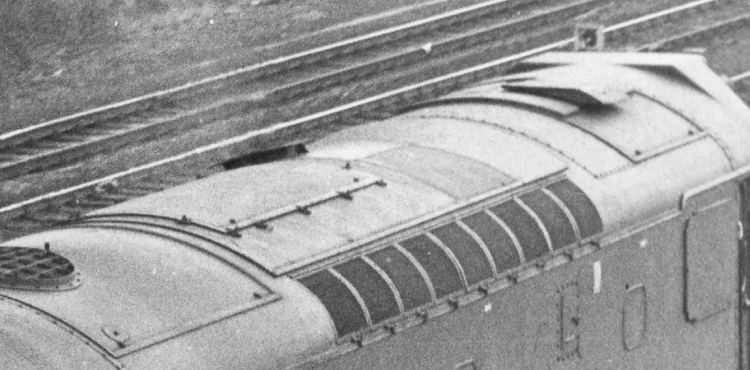

D5176 - D5232, D7568 - D7597 (25026 - 25082, 25218 - 25247) - boiler equipped

Following on from D5151 - D5175 came a batch of Class 25s with changes to the body styling and underframe equipment. These locomotives, apart from three were train heating boiler equipped. The removal of the cantrail level water filler, the repositioning of the engine exhaust to a position above the engine room, and the removal of the 'L' shaped raised panel gave the locomotive a much cleaner look, though not easily visible from the ground level.

This batch of locomotives underwent very few changes with regard to the roof. Most noticeable were the removal of the shroud above the boiler room and alterations to the engine exhaust and/or its surrounds.

![]()

D5233 - D5237 (25083 - 25087) - boiler equipped

After the orders for D5176 - D5232 & D7568 - D7597 the Class 25 design underwent considerable changes to its body, leading to improved air quality within the engine room and other spaces and a cleaner looking external appearance. For whatever reason the roof design and engine exhaust location reverted to that of the Class 24s.

This small batch of locomotives all visited Glasgow Works for a Classified repair, leading to winterisation of the roof area of all five lococomotives.

![]()

D5238 - D5299, D7500 - D7567, D7598 - D7677 (25088 - 25217, 25248 - 25327) - non-boilered

After the completion of D5233 - D5238 all remaining Class 25 orders would be without a train heating boiler. Thus the roof panel above what had been the boiler room would be greatly simplified with just a narrow raised panel above the electrical cubicle.

Exhaust roof panel at withdrawal: raised, square:

25003, 25088/089, 25095/097, 25100/101/102/104-107, 25110/112-119, 25120-124/126/127/129, 25130-136/138/139, 25141/142/143/145-148, 25151/152/154/157/158, 25160/161/163-169, 25170/173/175-179, 25180-187/189, 25190-196/198/199, 25200/201/204-209, 25210-214, 25249, 25250-253/257-259, 25262/263/265/268/269, 25270/273/274/276-279, 25281/282/284/285/287-289, 25292-294/297/298, 25301-303,307-309, 25312-317,319, 25320-327.

Exhaust roof panel at withdrawal: flush (Glasgow treatment):

25001/002/005-014, 25016-023/025, 25083-087/090/091/093/094/098, 25108/109, 25125, 25140/144/149, 25150/153/156, 25162, 25171/172, 25188, 25202, 25215-217, 25254/256, 25266, 25283/286, 25296, 25300/306.

Exhaust roof panel at withdrawal: raised 'L' shape (original design):

25004, 25015, 25024, 25092/096/099, 25103, 25111, 25137, 25155/159, 25174, 25197, 25203, 25248, 25260/261/264/267, 25271/272/275, 25280, 25290/291/295/299, 25304/305, 25310/311/318.

![]()

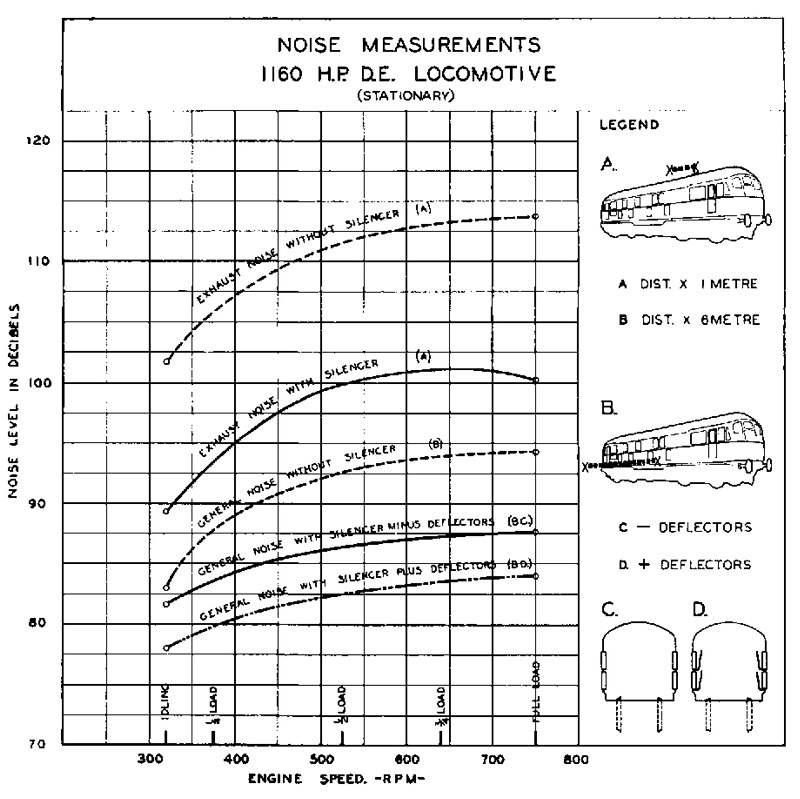

A graphic from the February 1959 Institution of Locomotive Engineers publication showing the results of stationary testing of a Class 24 for noise levels.

The Class 24s when built were equipped with exhaust silencers but these were gradually removed over time.

A study of noise levels on subway systems revealed an average decibel level of 72 - 76, but with highs reaching 120 decibels, both within the subway car and on platforms.

A rock concert could reach 120 decibels, a jet engine 135 and reportedly the explosion of Krakatoa produced 180 decibels.

![]()

Page added April 2nd 2022.

Last update August 24th 2023.