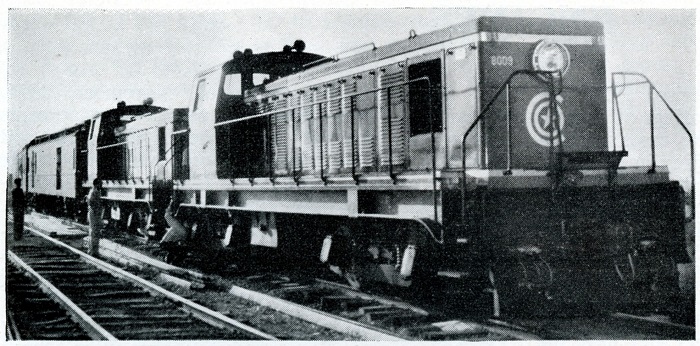

6LDA22-C powered mixed traffic locomotive

Numbering:

8001 - 8011 (original)

F452 - F461 (from 1969)

60801 - 60809 (from 1974)

During 1954 six locomotives were shipped from France to Cuba as part of the dieselisation of the railways on the island of Cuba. These were based on a class of 118 locomotives built by Brissoneau & Lotz, Creil for the SNCF.

Ownership appears to have been the United Railways of the Havanna & Regla Warehouses, which became part of the Western Railways of Cuba.

The locomotives varied little from their French counterparts, being powered by a Sulzer pressure charged 6LDA22-C engine, with a one hour output of 750hp at 850rpm. All the usual Sulzer features were included, the welded crankcase and underbed made up of cast steel and mild steel components, and tied in finely adjustable main bearings without cap studs in shear. Its dry weight including pressure charge and the underframe was 12,000lb. The four stroke engine was the latest version of the 6LDA22-B, most recently used in the French National Railways Bo-Bo Class 040.D. Improvements to the pressure charger providing higher air delivery pressures coupled to a slight increase in engine rpm and other minor improvements allowed the continuous output to be marginally increased to 740hp at 950rpm (as compared to 600hp at 900rpm for the French National Railways locomotives). Cylinder size was 220mm by 290mm (8.67in by 11.4in).

The electrical equipment was provided by the Nantes Works of Brissoneau & Lotz, principally a 360kW single bearing main generator with seperate excitation and an auxiliary generator with shunt winding, anti-compound winding and a seperately excited winding. The main traction and control apparatus was centralised within the control desk in the drivers cab. Although full engine output could be used over the 5.75 to 37mph speed range, there was no change in motor grouping or field weakening step. The transmission control system simply comprised a transition lever controlling engine speed with a rheostat which inserts variable resistance in the seperate excitation circuit of the exciter; a reverse control; line contactor, excitation contactor, anti-wheelslip contactor and two relays, a starting contactor, an idling electro-valve and an engine stopping solenoid..

Despite its weight of 68 tons and a maximum axleload of 17 tons the underfame was of substantial proportions. Four main longitudinal I beams, the outer two being 14.5in deep, the two inners being 9.5in deep, connected by eight transverse beams supported top deck plates of 6mm thickness. Removeable chequered plates form walkways around the perimeter of the locomotive, below these were the main cabling (right side) and air piping (left side). The bogie pivot portions attached to the underframe are of manganese steel.

A raised floor in the cab provided improved visibility and supported the one control desk in the cab. Controls were basic, one lever for reversing, the other for traction and braking. The long hood contains the engine, main & auxiliary generators, air compressor and traction motor blowers. The short hood contains air reservoirs and batteries.

The two bogies were of the non-bolster Pennsylvania type with compensating beams connecting the axleboxes on each side with the sole springing comprised of four helical steel springs at each side connecting the compensating beam with bearers welded to the bogie frame. The frame structure was all welded, the main side plates were two inches thick. Though a substantial centre transom was incorporated there were no end stays, which allowed easier access to the traction motors, no brake hanger brackets were required, the one brake shoe per wheel was fitted to the inside. Plain bearing axleboxes, standard to the SNCF were fitted.

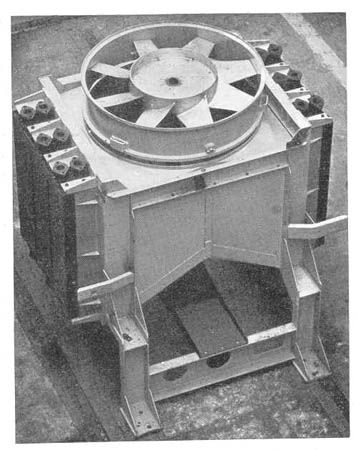

A decision was made to drive every auxiliary possible by mechanical means, by direct coupling to the engine main shaft or by Texrope drives from it. The roof level fan for the radiators was driven mechanically from the forward end of the engine crankshaft. Drive was through a fluid coupling using bevel gears to transition the drive to the vertical. Cooling air was drawn through the radiators and ejected upwards, engine room air passed through a Scam labyrith filter.

This order had a short delivery time, the contract was signed on July 29th 1954, the locomotives were shipped to Havanna in November. They were used on a variety of operations, hump shunting of 1,200 ton freights, yard freight up to 1,500 tons, line freights and light passenger trains upto 50mph. The locomotives were equipped for multiple unit operation.

A further seven locomotives of this class were delivered during 1955 after the initial order for six.

It is believed that all but one of these locomotives were scrapped during the 1980's. The survivor was converted for use on the 'Hershey' 1200V electrified system. A pantograph was fitted to the cab roof and the locomotive renumbered to 21202. It was still in service during 2002.

Partially based on an article in Diesel Railway Traction, January 1955.

![]()

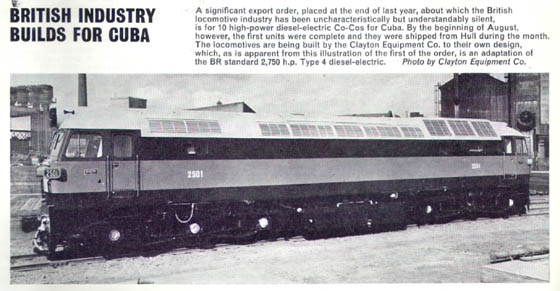

12LVA24 powered express locomotives

Numbering:

2501 - 2510 (original)

T975 - T984 (from 1969)

52501 - 52510 (from 1974)

During 1965 Brush were supplying part of a large order of Type 4's to British Railways which included five of the locomotives selected to carry the 12LVA24 'V' form engine as a comparison to the 12LDA28C fitted to the remainder of the class. Built at the same time were ten similar machines destined for export to Cuba.

These were very similar to the basic standard Type 4 design but sported a number of detail alterations. Internally the prime mover was the Sulzer 2,534hp 12LVA24 running at 1,050rpm coupled to Brush electrical equipment. This equipment required modification to handle the clockwise rotation of the engine - the twin bank engines rotated anticlockwise. Center buffer/drawgear connections were installed, Cuban operations demanded a large cabroof mounted headlight, corner number boxes for the cab front & a revised roof profile around the larger cooling group to accomodate equipment designed for tropical conditions. Only air-brakes were fitted, with the locomotives turned out in BR two-tone green livery.

Due to recent mergers/acquisitions involving Brush and its new parent being involved in contracts with USA firms it became prudent to 'disguise' the order. As detailed in the photograph's caption below the builder was identified as the Clayton Company of Hatton, Derbyshire, the locomotives even carrying the rectangular Clayton builders plate. They were completed at the Internal Combustion works at Derby situated alongside the Derby - Burton line, the works at that time had rail access.

And fourteen years later..........

Two views at Cardenas in 1994 showing the fate of the Sulzer powered Class 47 clones that were obtained for use on the island's railways at the same time that British Railways were receiving their 512 Class 47's.

Although it was believed that all these locomotives were cut up at about the same time it appears 52504 remained intact at least until February 1998 (& possibly longer), being noted at El Comino in a very sorry shape.

![]()

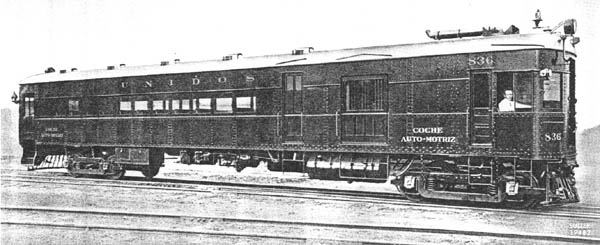

During 1939 two petrol engined railcars were each re-engined with a Sulzer 6LTD19 300hp engine.

![]()

Page added January 17th 2003.

Page updated April 17th 2024.

Return to Sulzer page

Return to site menu