The introduction of diesel locomotives to the French colonies in Africa started before World War Two with two locomotives delivered to the Tunisian Railways in 1925 - 1927 and two locomotives to Algeria in 1933. After World War Two the French company Alsthom produced a 'colonial standard' locomotive suited to hih temperatures, a sandy environment and only modest levels of maintenance. A medium speed Sulzer engine powered these diesel locomotives andwould also be installed in many fourgons (power vans) delivered to Africa. As detailed below other engine manufacturers would find their products fitted to some locomotives and railcars. The article below deals with this evolution.

The following article is a compilation of postings to the World Diesel Locomotive Group during February 2020, authored by Steve Palmano and used here with permission. The information complements and adds to the existing pages on this website featuring the Outre Mer locomotives in multiple countries.

Madagascar and Dakar-Niger Locomotives, Part 1

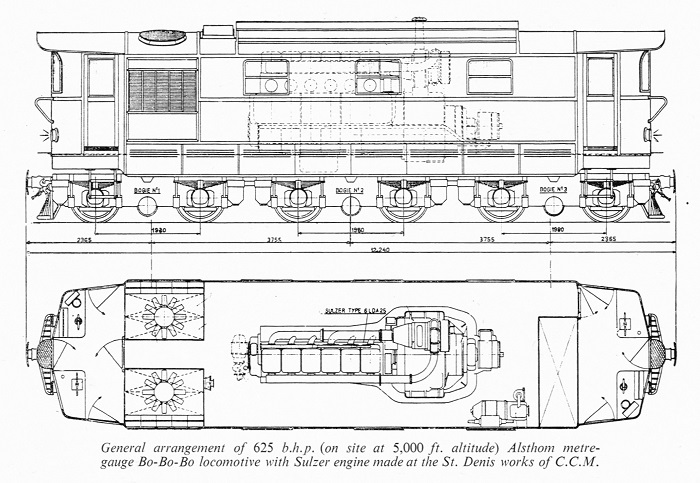

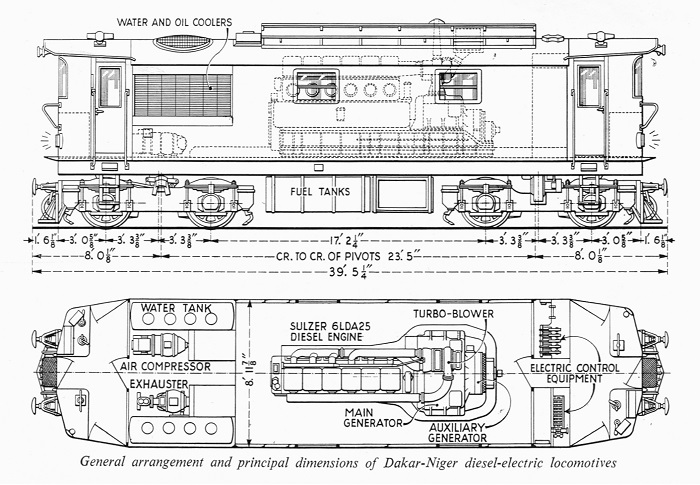

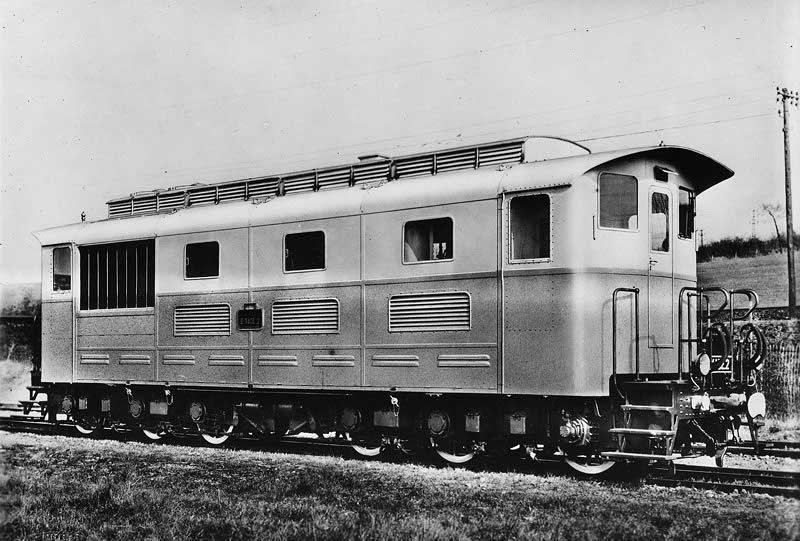

The Alsthom-Sulzer Bo-Bo pre-Outre Mer locomotive supplied to the Dakar-Niger Railway was very similar to the Alsthom-Sulzer Bo-Bo-Bo design for Madagascar as can be seen from their respective outline drawings.

To a first approximation, they could be seen as respectively 4- and 6-motor versions of the same basic design. Nonetheless, there are some differences of detail. The first batch of Madagascar locomotives was ordered in 1937, whereas the first batch of Dakar-Niger locomotives were ordered just before the start of World War II (WWII), which probably means in 1939. So if anything, the 4-motor variant was a derivative of the initial 6-motor model. Both though are definitely pre-WWII designs.

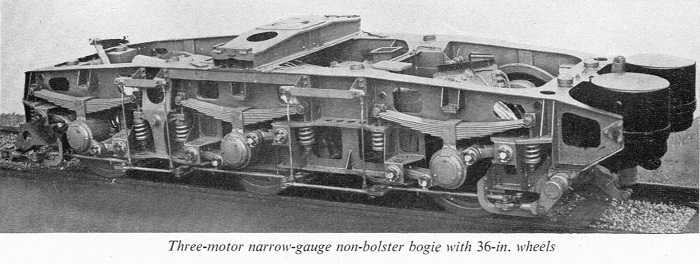

In the Madagascar case, six axles were required in order to meet a severely restricted axle loading of 10.5 tonnes (10.33 long tons) maximum. One imagines that the Bo-Bo-Bo wheel arrangement was chosen in deference to Co-Co due to the sharp curves found on the Madagascar railway system, which favoured a very short wheelbase bogie. As best that can be determined, that made it the first diesel locomotive to use the Bo-Bo-Bo (tribo) wheel arrangement in any of its forms, in this case the single-frame variety. The single-frame, articulated bogie Bo+Bo+Bo wheel arrangement had previously been used by General Electric for some standard gauge DC electric locomotives built for the Ferrocarril Mexicano in 1928. But the Madagascar locomotives were the first of any kind to combine the single frame with three non-articulated bogies. It was the start of a long association with the Bo-Bo-Bo wheel arrangement for Alsthom.

The Dakar-Niger locomotives, with a less restrictive axle loading requirement, had a Bo-Bo wheel arrangement. The bogies were mounted well towards the outer ends of the frame, and the couplers and buffers were mounted on the bogies rather than on the main frame. This approach was typically adopted to minimize coupler offset in sharp curves. Buff and drag forces were taken through the outer bogie frames to the centre pins, and through the main frame between the bogie centre pins. The Madagascar locomotive also had the couplers and buffers mounted on the bogies.

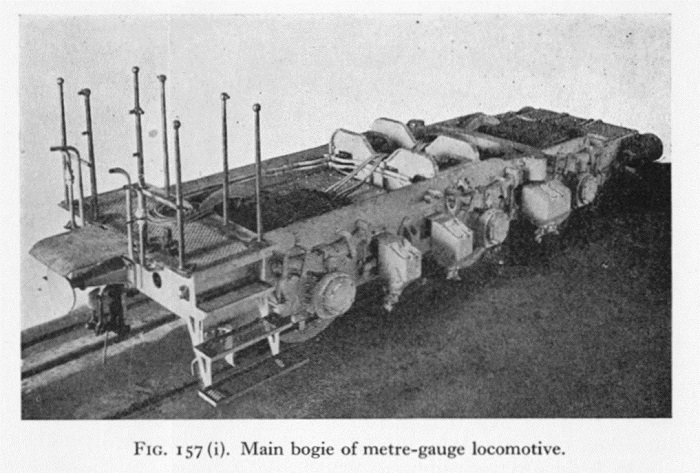

In both cases the bogies were of simple, rigid bolster fabricated plate-frame design with unequalized leaf spring primary suspension. What provision was made for lateral freedom of the centre bogie of the Madagascar locomotive, and how it was done is unknown. Typically single-frame tribo locomotives allow a considerable amount of high-compliance lateral movement for the centre bogie, with the outer bogies doing all of the guidance work in curves.

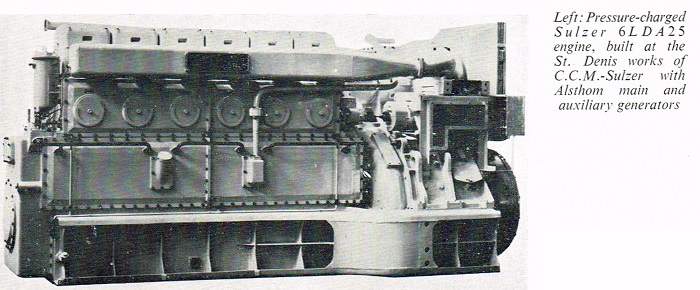

Both locomotives were fitted with the Sulzer 6LDA25 engine. The European one-hour gross rating for this engine was 735 hp at 850 rev/min, and the site rating for Madagascar was 625 hp at 850 rev/min, taking into account the high altitude reached by parts of the railway system, above 1500 metres, and the high ambient temperatures. The Dakar-Niger locomotives were set to a site continuous rating of 610 hp at 795 rev/min, as compared with the European continuous rating of 655 hp. At the time, Sulzer quoted both one-hour and continuous ratings for its engines. And often, the control systems fitted to Sulzer-engined locomotives allowed access to the one-hour rating when the throttle handle was in the final notch, with the continuous rating provided in the penultimate notch. As part of this, the throttle handle was spring loaded to return to the penultimate notch, so that it had to be held in the final notch, this helping to prevent excessive time being spent at the one-hour rating. (As an aside, this spring-loaded final notch was found on the Commonwealth Railways NSU class of 1964, and of necessity, for MU compatibility on the NT class of 1965.) A reasonable inference is that whereas the Madagascar locomotive control system allowed access to the one-hour rating, that on the Dakar-Niger locomotives did not.

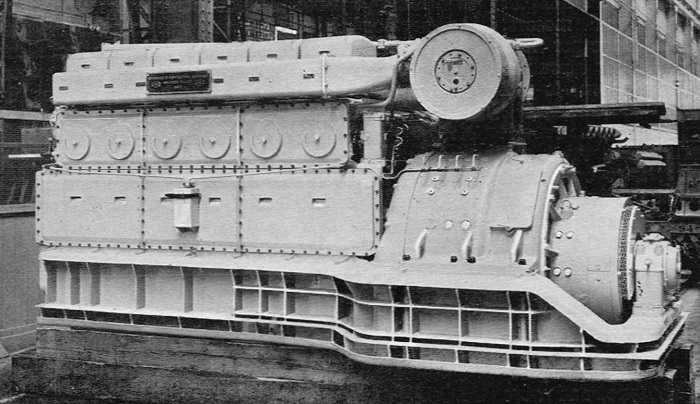

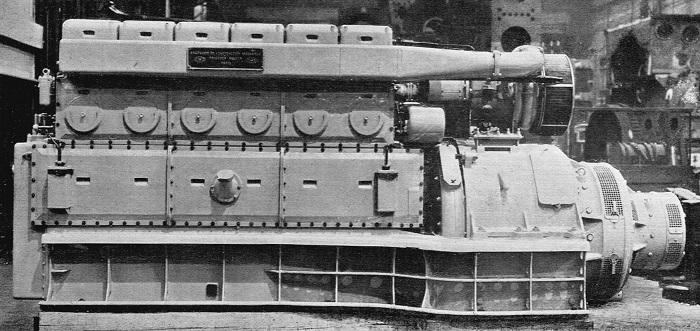

Both also had the pre-WWII arrangement whereby the base structure upon which the engine-generator combination was mounted was extended beyond the generator assembly to support a bearing at the outer end of the auxiliary generator. That is, the generator combination was not fully overhung from the engine, as became normal in later practice. Possibly Sulzer was at the time concerned about the effects of an overhung load on the crankshafts of its engines. The end-bearing is clearly shown in this picture of the engine-generator assembly for the Dakar-Niger locomotive:

Reference to the outline diagram will show that the Madagascar locomotives had an additional small machine overhung outside of the end-bearing. This was the exciter for the Alsthom 'anti-shunt' system of traction motor field weakening.

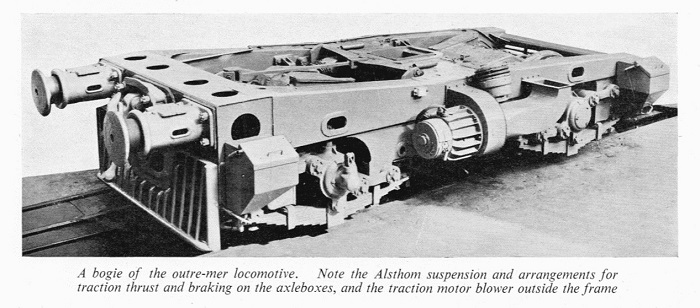

The Madagascar locomotive had six relatively small self-ventilated traction motors, so it did not require a separate traction motor blower. In the Dakar-Niger case, the four larger motors required separate ventilation, and this was provided by a pair of motor-driven blowers. These were not fitted in the locomotive body, but rather one on each of the bogie frames with diagonally opposite disposition. They drew air from inside the locomotive body, though. On the layout diagram, one traction motor blower may be seen on the right-hand bogie. This unusual arrangement was perpetuated by Alsthom on some its post-WWII designs, including the definitive 'Outre Mer' type.

The auxiliaries were electrically driven, including the cooling system fans, the air compressors and, on the Dakar-Niger locomotives, the vacuum exhausters. The French Outre Mer systems at the time were mostly vacuum-braked, Madagascar being an exception in using air braking.

The Dakar-Niger locomotive had a conventional underslung fuel tanks. There was no room for such on the Madagascar locomotive. From the diagram, it looks if the fuel tanks were fitted in the body lower sides, perhaps outside of the mainframe longitudinals, but this is unconfirmed.

The Dakar-Niger locomotive is known to have had a control system that provided six throttle notches based upon three set engine speeds. In the late 1930s Sulzer was using control systems that were based upon the Brown Boveri (BBC) servo-field system, itself a derivative of the 1914 Lemp system, which used a small number of engine speeds and provided for several load control settings at each speed to achieve the requisite number of notches. Probably the Madagascar locomotive had a similar system, but no details have come to light. As originally built, the Dakar-Niger design had no traction motor field weakening, whereas the Madagascar model had Alsthom's own 'anti-shunt' system, as already mentioned. Multiple unit equipment was fitted to the Dakar-Niger locomotives.

The early Madagascar locomotives weighed 62 tonnes (61 long tons), had a starting tractive effort of 26,500 lbf, a continuous tractive effort of 17,600 lbf at 9.65 mile/h, and a top speed of 60 km/h (37 mile/h). The Dakar-Niger locomotives weighed 48 tonnes (47.25long tons), with a starting tractive effort of 15,400 lbf. Continuous tractive effort was quoted as 7180 lbf, although without a corresponding speed. Top speed was 70 km/h (43.5 mile/h).

![]()

Madagascar and Dakar-Niger Locomotives, Part 2

Firstly, there is some additional information on the power settings of the Sulzer 6LDA25 engines used in these locomotives. In Part 1 it was stated:

1/ 'Both locomotives were fitted with the Sulzer 6LDA25 engine. The European one-hour gross rating for this engine was 735 hp at 850 rev/min, and the site rating for Madagascar was 625 hp at 850 rev/min, taking into account the high altitude reached by parts of the railway system, above 1500 metres, and the high ambient temperatures. The Dakar-Niger locomotives were set to a site continuous rating of 610 hp at 795 rev/min, as compared with the European continuous rating of 655 hp.'

2/ 'A reasonable inference is that whereas the Madagascar locomotive control system allowed access to the one-hour rating, that on the Dakar-Niger locomotives did not.'

In fact the Madagascar site rating was 625 hp at 790 rev/min on a continuous basis. Thus it would appear that like the Dakar-Niger locomotives, the Madagascar locomotives had a control system that did not access the one-hour rating. This is confirmed by Hinde & Hinde in their book 'Electric and Diesel-Electric Locomotives' of 1948, wherein 790 rev/min is stated to be the maximum operating speed of the engine, although the other, lower operating speeds were not stated.

Whether the continuous rating speed was 790 or 795 rev/min is unclear, but in any event, both would be within the likely range of governor setting precision, whichever was the target, so it is a moot point. Later on, it was given as 800 rev/min.

As already noted, the first tranche of three Madagascar locomotives was ordered in 1937, with first completion during 1939. However, WWII caused delays, and they did not enter service until 1943-44. Meanwhile, another 2 had been ordered, and they entered service in 1945-46. After WWII, another 5 were ordered, and these entered service in 1952. Track improvements meanwhile allowed these to be built to the slightly higher weight of 66 tonnes (65 long tons), with an axle-loading of 11 tonnes (10.8 long tons). A final 2 were ordered with delivery in 1953, for a total of 12.

It has been reported that the final two were diverted to the Conakry-Niger railway in West Africa, with the result that a pair of replacements were built for Madagascar. And that these had a higher site rating of 675 hp. But this is unconfirmed. Possibly it was something that was contemplated but did not happen.

As its next step, the Madagascar system turned to the new standard Alsthom end-cab Bo-Bo hood unit powered by the MGO high-speed engine. It was the first customer for this Cape-metre gauge variant of the Alsthom standard design. With an axle loading of 11.5 tonnes now permissible, the simpler 46-tonne four-axle locomotive was a good fit. There was no longer a need for the more complex tribo design.

The initial Dakar-Niger 1939 order was for six locomotives, which were placed into service during 1947-48. A 1945 order was placed for 10 more of which 9 entered service in 1949-50, with the 10th in 1951. This had an improved traction motor design that incorporated one stage of field weakening. With this came a longer wheelbase bogie, 2.4 metres (7'10") rather than 2.0 metres (6'6.75"). This resulted in the one-hour tractive effort increasing to 16,000 lbf at 10 mile/h from 8400 lbf at 22 mile/h. Some of the 15 previous locomotives may have been upgraded with the new traction motors (and presumably the bogies). The Dakar-Niger railway moved on to other Outre Mer types in the early 1950s.

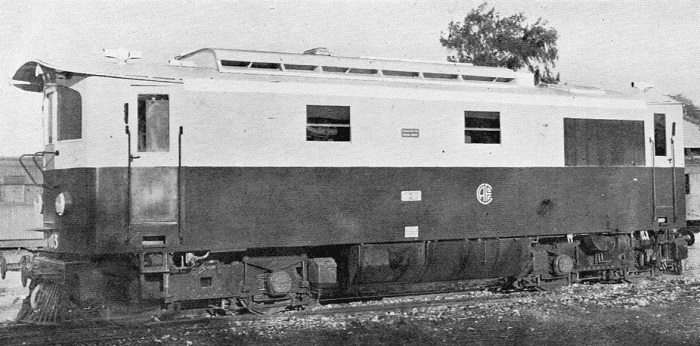

The 12 Madagascar and 16 Dakar-Niger Alsthom-Sulzer locomotives were reported to have performed well in service. Although relatively simple designs of modest power output and with moderate top speeds, they suited the railways and their operations as they were at the time and provided a good start on their respective dieselization programmes. The Dakar-Niger design was also the direct antecedent of the definitive Alsthom-Sulzer Outre Mer type.

![]()

The Phosphates Pair

Fellow-travellers to the Alsthom-Sulzer pre-Outre Mer types were the so-called 'Phosphates Pair', which also used the Sulzer 6LDA25 engine.

The two metre-gauge locomotives were built in 1938 for the Phosphates Company of Algeria, taken over by Algerian railways during WWII, and then sold to Tunisian Railways just after the war. There they were joined later by the Alsthom Outre Mer type, also with the Sulzer 6LDA25 engine.

They were built by Marine-Homecourt, with electrical equipment by Jeumont. The wheel arrangement was either Co-Co or Co+Co, which of the two is unclear. The end-platforms mounted on the bogies were not unlike those found on some articulated-bogie electric locomotives of the time, and Hinde & Hinde stated that they were articulated. On the other hand, a photograph of one of the bogies does not show any obvious signs of an articulation joint, although neither does it preclude the possibility. One would probably have to find the original French technical literature to make a determination. Articulation would certainly have been fairly normal in 1938, particularly for a heavy-haul slow-speed locomotive. On the other hand, independent bogies were already in use for lower-powered locomotives, and Alsthom chose that form for both the Madagascar and Dakar-Niger designs, also with lowish top speeds.

From the photograph it does appear as if the innermost traction motor was mounted inboard of its associated axle. Possibly the bogie had tandem-mounted motors, although the position of the centre motor is not obvious.

The site continuous rating of the Sulzer 6LDA25 engine was quoted as 635 hp. According to Hinde & Hinde, the control system provided 8 notches using 3 engine speeds, namely 460, 760 and 850 rev/min. The last-mentioned speed suggests that the one-hour rating might have been accessible on the final notch, with a lower load setting at the same speed on the penultimate notch. The electrical system included a Jeumont axle-driven exciter and a Brown Boveri servo field regulator. The six traction motors were self-ventilated, and no field weakening was provided. Given the low maximum speed of 60 km/h (37 mile/h), that would hardly have been necessary. Continuous tractive effort was 8815 lbf at 18.6 mile/h.

Weight was said to be 66 tonnes (65 long tons) with an axle loading of 11 tonnes (10.8 long tons). That made them just a bit heavier than the early Madagascar locomotives, but the same weight as the later examples. Like the Madagascar design, the bogies occupied the whole underframe space, so the fuel tanks were mounted elsewhere, possibly in the lower body sides.

![]()

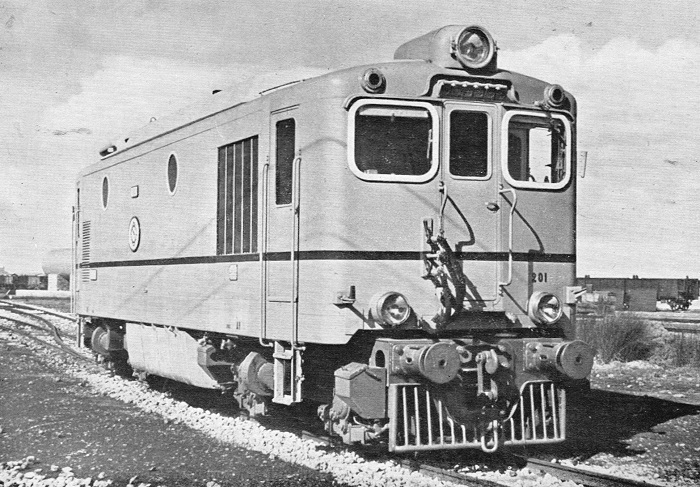

The Definitive Outre-Mer Type

The Madagascar and Dakar-Niger locomotives can be viewed as pre-WWII ad hoc designs whose building continued in the early-post-WWII period in order to meet immediate motive power demands. At the same time it was evidently planned to develop a standard design, proximate to the Dakar-Niger locomotive in terms of capacity, weight and axle loading, for use on the various Outre-Mer metre gauge systems. The result was the Alsthom-Sulzer Outre-Mer type, still using the Sulzer 6LDA25 engine and at the same site gross power rating of 610 hp, and with an axle loading of 13 tonnes. The first build was 17 units for the Sfax-Gafsa Railway in Tunisia, with delivery in 1950-51.

As may be seen, this locomotive had an appearance, which although not really streamlined, was certainly less utilitarian than had been its predecessor. It still retained the double-boxcab form, and the buffers and couplers were still mounted on the bogie headstocks rather than on the main frame.

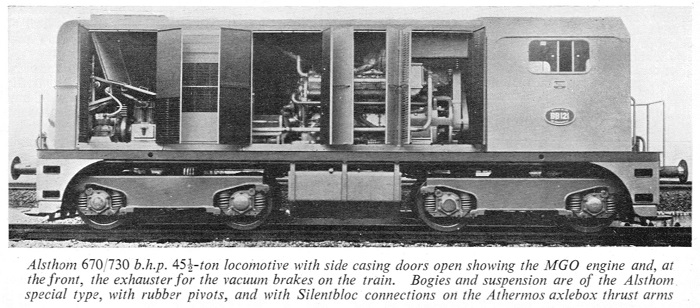

The Sulzer 6LDA25 engine had an NTP gross one-hour rating of 735 hp at 850 rev/min, and a continuous rating of 655 hp at 800 rev/min. The site continuous rating was 610 hp at 800 rev/min, the site conditions involving ambient temperatures up to 53C. The base upon which the engine-generator set was mounted was shorter than before, with the generator group fully overhung.

The generator group comprised the main generator, the auxiliary generator and the antishunt exciter. The auxiliary generator was quite large, at 60 kW, reflecting the fact that all auxiliaries, cooling fan, traction motor blowers, air compressor and vacuum exhauster were electrically operated. As with the Dakar-Niger locomotives, the traction motor blowers were mounted on the bogie sideframes, in this case with both on the same side of the locomotive. They drew filtered air from within the locomotive body. The Sfax-Gafsa locomotives were fitted with a centrifugal air filtration system given that they operated in an area that was prone to sandstorms. Whether the later builds were also so-fitted is unknown, but it seems likely. Some railway systems that had to contend with sandstorm conditions preferred cab (or cowl) units with special filtration systems, Sudan Railways being another example. It may have been easier to keep these airtight.

The bogies were of a new design, of the fabricated boxframe type, although still of the rigid-bolster layout, given that the top speed remained at 70 km/h (43.5 mile/h).

The bogie frame siderails were tapered vertically from the outer to the inner ends; the deeper outer half carried the buff and drag forces between the buffers/couplers and the centre pivots. A key feature was that there were no pedestals, the axleboxes being located by a Watt linkage with Silentbloc bushes at the mounting points of the arm. Alsthom had introduced this arrangement with its SNCF CC7000 prototype DC electric locomotive of 1949, and it then became a signature feature on many subsequent Alsthom locomotives. By way of the 'Thomson' connection, the Watt linkage design passed to British Thomson-Houston in the UK, and thence became the norm for AEI Traction designed locomotives. In the Outre-Mer case, primary suspension was by underslung leaf springs, as had been used for CC7000. Whether the centre pivot was resiliently mounted is unknown, but it certainly looks as if it could have been.

The Outre-Mer locomotives had a newer Sulzer control system, a design that dated back to 1939 and was first used on the RSR Thailand 651 class locomotives. In this, Sulzer had moved away from the BBC precept of obtaining the desired number of notches through various combinations of relatively small numbers each of engine speeds and load control points, to a system that used 8 evenly-spaced engine speeds, each with its own proportional load control point, to provide 8 running notches. These were usually accompanied by two fixed-excitation starting notches at minimum engine speed, making for 10 notches in all. Part of this scheme was a new engine governor that incorporated an integral electro-hydraulic speed control, and an integral load control pilot valve.

Within the basic Sulzer control system parameters, electrical equipment suppliers were free to execute the details as they saw fit. The Sulzer system was essentially of the Lemp 1914 type, and so governor-signalled load control was required. Beyond that, though individual suppliers chose their own pathway. Alsthom thus opted to use its antishunt system of field weakening in the Outre-Mer locomotives. This was effectively continuously variable rather than coarsely stepped as with conventional switched field-weakening schemes. It probably contributed to the fact that full loading of the engine was maintained right up to the maximum service speed of 70 km/h. With locomotives of this era, the unloading point often occurred at somewhat below the maximum speed. At the lower end of the range, full engine loading was possible down to 6.5 mile/h, which was probably close to the minimum one-hour speed.

Starting tractive effort was 30,000 lbf, which corresponds to about 25% adhesion. Continuous tractive effort was 16,500 lbf at 8.75 mile/h. Weight was quoted as 52 tons, but this may have been 52 tonnes, which is 51 long tons.

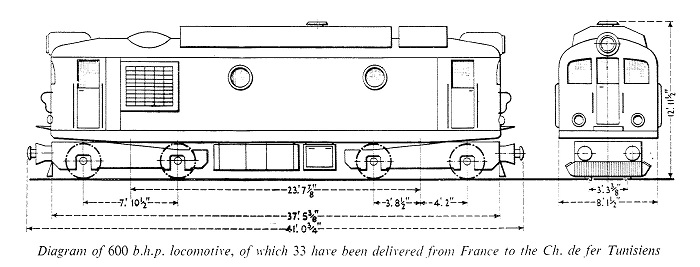

The second build of the Outre-Mer type was 33 units for the CF Tunisia (CFT), which appear to have been delivered in 1951-52. Possibly these also had centrifugal filtration equipment. Weight was said to be 51 tons, most likely long tons.

The third and final build was of 6 units for Reseau Ferre du Cameroun (RFC), delivered in 1951-52.

That gave a total of 56 units over the 1950-52 period, as compared with the 28 pre-Outre-Mer units (12 Madagascar and 16 Dakar-Niger) over the 1939-52 period.

By all accounts the Outre-Mer type performed very well in service over quite a long period. That no more were built is probably less a reflection on the locomotives themselves, but more of a circumstantial outcome. Having reached something of a plateau in term of locomotive development, it appears that those in charge of the Outre-Mer railway systems firstly wanted to try diversification of suppliers and locomotive types (within the framework of the 52-tonne four-axle concept) and following that exercise, simplification was the order of the day.

Whether Alsthom contemplated a tribo version of the same basic design, as a successor to the Madagascar type, is unknown. In the event, it was not required in Madagascar. But Alsthom did build the tribo type as part of its following generation of standard locomotives.

![]()

Diversification Part 1 - The Renault Locomotives

The building of the definitive Alsthom-Sulzer Outre-Mer type locomotives was followed by a period of diversification. One may deduce that this had several objectives, namely to involve locomotive and engine builders other than Alsthom and Sulzer, to try out locomotives fitted with both mechanical and hydraulic transmissions, and to try out locomotives fitted with two relatively small railcar-type engines. The last-mentioned might not have been a primary objective, but could well have stemmed from the desire to try mechanical transmissions. In this case there might have been an element of 'supplier push' from Renault, who evidently wanted to get into the locomotive market using much of the technology it had developed for diesel-mechanical railcars.

All of this 'experimental' work was done with Bo-Bo/B-B locomotives in the 52 tonne weight range, and for the most part of the double cab type, following the precedent of the Outre-Mer and pre-Outre Mer locomotives. These new types were dispersed to the various French West African railway systems.

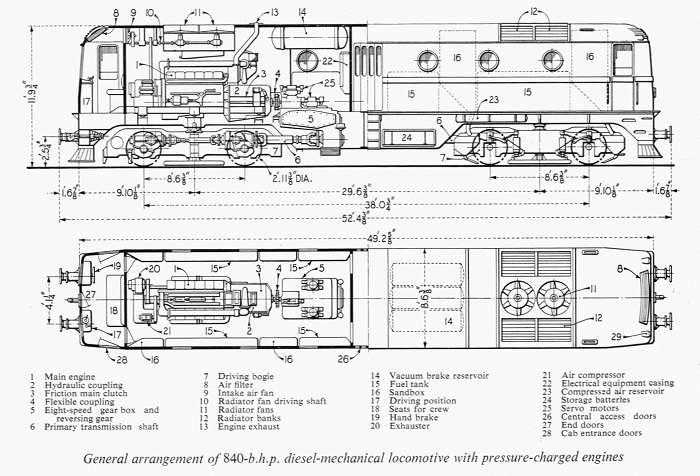

The first of the new types was a Renault diesel-mechanical design, model 5040, of which 5 were built for the Benin-Niger railway in 1952-53. Renault also built a standard-gauge prototype in 1952, model 5042, that was trialled on the SNCF as the 040DF type. The 5040 and 5042 conformed to a common design that could be adapted both for metre gauge and standard gauge applications. It was reported that Renault saw the design as an alternative to the standard Outre-Mer design on the one hand, and the SNCF 040DE standard locomotive on the other.

The Benin-Niger locomotives were fitted with two 420 hp Renault 565 V12 engines, each driving a pair of bogie axles via a fluid coupling, a friction clutch and an electropneumatically operated 8-speed gearbox. This engine and driveline combination was basically similar to that used on the railcars, although the latter had 4- or 5-speed gearboxes.

The potentially high efficiency of the mechanical transmission seems to have been a holy grail for some locomotive designers. The fact that the necessarily stepped nature of the torque multiplication curve meant poor power utilization over much of the speed range seems to have been overlooked or dismissed as an acceptable tradeoff. For railcars, which typically had favourable power-to-weight ratios and moderate loaded-to-tare weight ratios, and for small shunting locomotives whose full engine power was rarely required, this poor power utilization was not of much consequence. But it was significant for line-service locomotives, which operated with very variable trailing loads and relatively modest power-to-weight ratios when hauling maximum trailing loads. Not only that, but the definite break in tractive effort that occurred at each gearchange was unwelcome in terms of train handling. I suspect that these lessons were quickly relearned by Renault and the diesel-mechanical locomotive idea was abandoned. As far as I know the only Renault line-service diesel-mechanical locomotive builds were the SNCF prototype and the five for Benin-Niger.

The result was that the same basic locomotive design was reworked to use hydraulic transmissions, as the model 5044, of which 13 were supplied to the Conakry-Niger railway in 1953-55. They had the same Renault 565 engines, but Voith L24r twin-converter hydraulic transmissions were used in place of the Renault mechanical transmissions. That there was now a second diesel-hydraulic type may have been happenstance rather than part of the original diversity plan.

These B-B locomotives were of the double-boxcab type, continuing the established practice for Outre-Mer locomotives, with structures derived from Renault's railcar practice. They had fabricated, rigid-bolster bogies with conventional overhung leaf springs with coil auxiliaries. The buffers and couplers were mounted normally on the mainframe headstocks, this being a departure from established Outre Mer practice. Being twin-engined with a symmetrical equipment layout, they avoided the problems of equipment placement and weight distribution that affect single-engined locomotives with shaft drives. The basic weight for the diesel-mechanical model was 48 tons (probably 48 tonnes), with optional ballasting up to 52 tons (52 tonnes). Thus they could be comparable in weight to the definitive Outre Mer type, and were somewhat more powerful. At 15 metres (49'3") over headstocks, as compared with 11.4 metres (37'5"), they were noticeably longer, though. I haven't found what I should consider to be reliable numbers for the actual weights of the Benin-Niger and Conakry-Niger locomotives. Neither have I seen top speed numbers. A maximum operating speed of 70 km/h would have been consistent with established Outre-Mer practice, so probably the locomotives were geared for somewhere near this number. The SNCF 040DF was geared for 130 km/h, so the basic design was capable of much more than 70 km/h.

The Renault V12 engines, whose basic design dated back to the early 1930s, were widely used in French-built railcars, with some of those operating on the Outre-Mer systems. They were also used in some shunting locomotives, so were familiar equipment. The 565 model itself was new at the time, being a turbocharged version of the established 517.

I have not seen anything about the control systems of the Renault 5040 and 5044 models. In diesel-mechanical railcar service, the Renault engines were usually fitted with minimum-maximum type governors with either direct, i.e. mechanical or electropneumatic control of the fuel rod position. Certainly fuel rate rather than engine speed would be the appropriate control parameter with mechanical transmission. With all-converter hydraulic transmissions, such as the Voith L24r, engine speed was the preferred control parameter, but fuel rate control could also be used. From the available photographs, it looks as if the Conakry-Niger locomotives were fitted for multiple unit operation.

Setting aside the issues associated with mechanical transmissions, how these locomotives performed in service appears not to have been recorded. That they were not repeated could be indicative of less-than-stellar performance, but even had they matched the Outre-Mer type, they would still have been overtaken by events.

![]()

Diversification Part 2 - The Alsthom Twin-Engined Locomotives

Second of the 'diversification' locomotive types was a twin-engined design by Alsthom. Five were built in 1953 for the Abidjan-Niger railway. Four of these had Renault engines, and one had Saurer engines.

One may wonder whether this was part of the 'railcar engine' trial, in that it was thought that electric as well as mechanical transmission should be included, or whether perhaps Alsthom, seeing what was happening, stepped forward with a diesel-electric design just in case the use of twin engines was preferred in the future. The use of a Saurer engine in one unit was presumably an engine supplier diversification exercise.

Alsthom had previously used the Renault V12 engine in shunting locomotives, so would already have had available a suitable main generator for it. Thus the main design work required would have been for the mechanical side. At first pass, the locomotive looked like a slightly longer version of the Outre-Mer standard design. It retained bogies that carried the buffers and couplers at their outer ends, but they differed in detail design. They still used the Watt linkage for axlebox location, but instead of the underhung leaf springs they used Silentblocs. Also, they had conical rubber pivots of the type subsequently standardized by Alsthom. These would have provided a modicum of secondary springing. The traction motor blowers were no longer mounted on the bogie frames, but were inside the body, mounted on and driven from the ends of the generator shafts. The cooling fans were mechanically driven from the engines.

The Renault 565 420 hp engines were essentially the same as were used on the Renault diesel-mechanical and diesel-hydraulic locomotives. The Saurer SBD V12 engines installed in the fifth locomotive provided 450 hp each, or 900 hp total. French Saurer was also an established supplier of railcar engines, so its engines were familiar to the operators.

Almost certainly Alsthom would have used a simple 'inherent characteristic' load control system (of the Lemp 1924 type) in these locomotives, with engine speed as the control parameter. One known feature is that in normal operation the engine speed was limited to 1350 rev/min, on the basis that this provided adequate power for normal operations, probably around 85% of maximum. The full engine speed of 1500 rev/min was accessible only by breaking a seal and operating a switch in the engine room, which operation came with a 'please explain' order.

How these locomotives performed is unknown, although it seems unlikely that they would have easily matched the Outre-Mer units in terms of availability and monthly distances run. But that was effectively academic. At the time these were built, Alsthom would already have been working on its new and simpler standard design, so would have seen that with high probability, this is where the future lay.

Also, all 23 of these twin-engined locomotives (5 Alsthom, 18 Renault) went to French West African roads that had not received any of the preceding Alsthom-Sulzer designs, so direct comparisons would not easily have been made.

An observation is that in this sub-fleet this fleet were found diesel-mechanical and diesel-hydraulic locomotives that, transmissions aside, were essentially identical, and diesel-electric locomotives that although mechanically not identical, were generally similar and which shared the same powerplants as the diesel-mechanical and diesel-hydraulic types. No other cases involving the three transmission forms comes to mind, although there were some diesel-hydraulic and diesel-electric pairs and near pairs.

![]()

Diversification Part 3 - The AFL-Sulzer-Voith Diesel-Hydraulic Locomotives

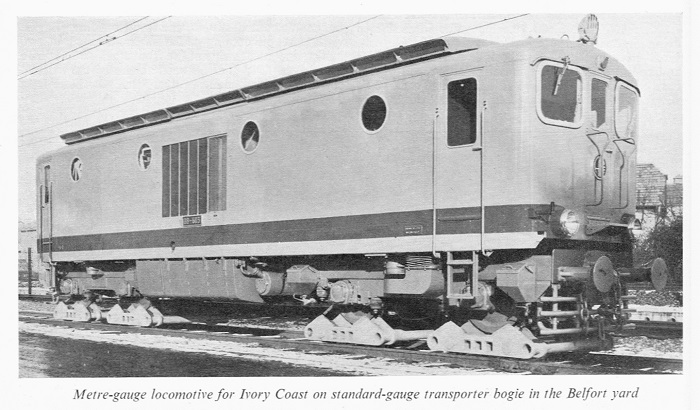

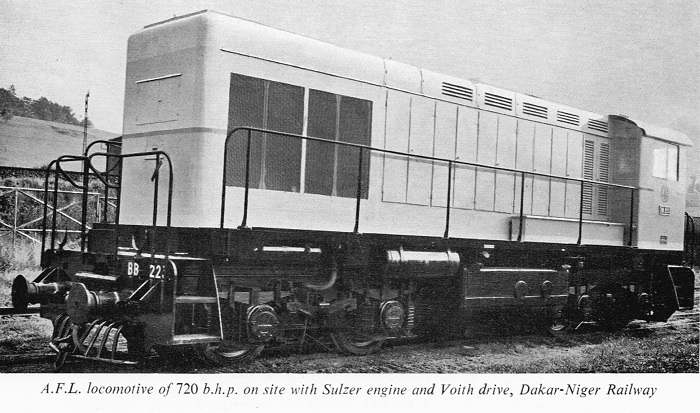

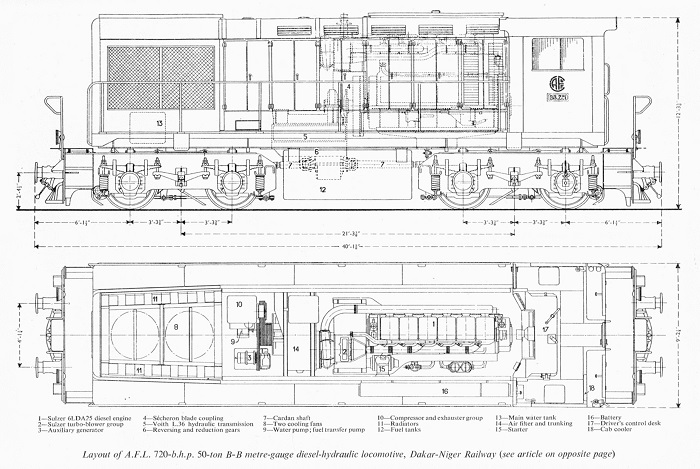

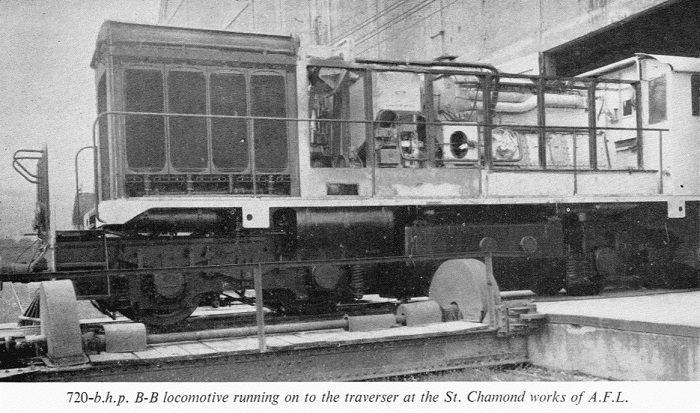

Third and last of the diversification types was a Sulzer-engined diesel-hydraulic locomotive of which 8 were built by Ateliers et Forges de la Loire (AFL) for the Dakar-Niger Railway in 1954.

These locomotives represented both supplier diversity and transmission diversity. I am not sure of the exact corporate sequence, but AFL appears also to have been known as CAFL (Cie. Ateliers et Forges de la Loire), and by the time the locomotives at interest were built, had absorbed the former Homecourt organization. Whether the order was placed before this is unknown. Homecourt had built the two 'Phosphates' locomotives mentioned earlier, and was a builder of Sulzer-engined industrial shunting locomotives. Homecourt/AFL/CAFL evidently had a strong relationship with Sulzer, and went on to build Sulzer-engined locomotives for SNCF, including the 060DA and 68000 classes.

I think it is reasonable to assume that these locomotives were also the primary Outre-Mer experiment with hydraulic transmission, and that as already said, the Renault diesel-hydraulics were more a happenstance spinoff from the diesel-mechanical design. The use of a hydraulic transmission on a line-service locomotive was unusual for AFL, who was associated mainly with the diesel-electric type.

These AFL locomotives had Sulzer 6LDA25 engines. Given that they were headed for the Dakar-Niger system, which already operated diesel-electric locomotives with this engine, commonality could have been a factor in that choice. Also, the common engine would have made comparison of the two transmissions systems easier, in that it eliminated an independent variable. The use of a medium-speed engine with hydraulic transmission was not unknown, but it was much less common than the high-speed engine/hydraulic transmission combination. Whilst there was no fundamental reason why the medium-speed /hydraulic combination would not work, torsional vibration problems - the avoidance of which was major issue in diesel-hydraulic locomotive design - might have loomed larger. In that respect, the Sulzer engine may not have been all that benign. It is known for example that AEI ran into torsional vibration problems when it paired the Sulzer 6LDA28 engine with the GE-design main generator and its auxiliary gear drive system.

AFL chose the Voith L36rd triple-converter transmission. With the benefit of hindsight, one may see that it was doubly wise in both choosing the Voith and choosing an all-converter model, although for a medium-speed engine, a transmission that used a fluid coupling for the final stage would probably have been inappropriate. The final-stage fluid coupling was used in the pursuit of higher efficiency, but it came at the expense of poor power utilization in the upper range, which was probably not desirable for the application in question. The Dakar-Niger is known to have worked its Alsthom-Sulzer locomotives at full power for long stretches when out on the line.

An unusual feature was that instead of the customary universal-jointed cardan shaft between the engine and transmission, AFL used a Secheron blade coupling of a type that had been developed for use in electric locomotives with bogie-mounted motors. Whether this helped damped torsional vibrations coming from the engine is unknown, but it might have done better than the conventional arrangement.

In one respect these locomotives departed from established Outre-Mer practice and in fact pointed to the future. They were single end-cab hood units rather than being of the double boxcab type. They might have been the first diesel-hydraulic line-service locomotives to use the hood bodyform. That aside an established feature that they did retain was having the buffers and couplers mounted on the bogie headstocks. The end-platforms were also mounted on the bogies rather than the main frame. The bogies themselves were of conventional rigid-bolster plate-frame design, although with equalized suspension, which was a departure.

The engine was mounted just ahead of the cab, driving forward to the transmission whose drop-box was closer to the front bogie than to the rear. The cooling group was at the extreme front, presumably to get some weight balance. The cooling fans and other auxiliaries were mechanically driven from the non-input end of the transmission. The fuel tanks were underslung between the bogies, evidently one each side the transmission shafts.

By the time these locomotives were built, the Sulzer 6LDA25 had been uprated to 850 hp at 850 rev/min on a one-hour, gross basis. The site rating was 720 hp at 850 rev/min. At 850 rev/min, this would have been the one-hour rating, so it may be deduced that these locomotives had a control system that allowed access to the one-hour rating. I haven't seen any details on the control system, but by 1954 a new Sulzer governor with pneumatic continuously variable speed control was available (it dates from 1952-53), and this, without the usual load control gear, would have been suitable for a diesel-hydraulic locomotive. This governor was used both with stepped and continuously variable throttle controls. Maximum speed was 70 km/h (43.5 mile/h), and weight was quoted as 50 tons, probably 50 tonnes.

As with the other 'diversification' locomotives, how this AFL group performed was probably academic given that a new standard design was imminent. Evidently the Outre-Mer folks were not persuaded to go down the hydraulic transmission path. In fact the French locomotive builders as a group made very little use of hydraulic transmissions in line-service locomotives.

A New Alsthom Standard Locomotive

By mid-1954, the fleet of Outre-Mer locomotives at interest comprised;

28 of the Alsthom-Sulzer pre-Outre-Mer type (12 Madagascar Bo-Bo-Bo and 16 Dakar-Niger Bo-Bo)

56 of the definitive Alsthom-Sulzer Outre-Mer type (Bo-Bo)

31 of the 'diversification' group, some of which were yet to be delivered (5 Renault diesel-mechanical, 13 Renault diesel-hydraulic, 5 Alsthom twin-engine and 8 AFL diesel-hydraulic)

That made for a total of 115 locomotives within the Outre-Mer group, the subject of this series of postings.

Incidentally, in this context the term 'Outre-Mer' covers locomotives which were designed under the aegis of OFEROM, Office Central des Chemins de Fer d'Outre-Mer (Central Office for Overseas Railways). I think that OFEROM had operational responsibility for some of railways that received these locomotives, such as the French West African group and in Madagascar. But there were also systems outside of the OFEROM operation sphere that received OFEROM locomotives, such as CFT and Sfax-Gafsa in Tunisia. These two roads accounted for 50 of the 115 locomotives.

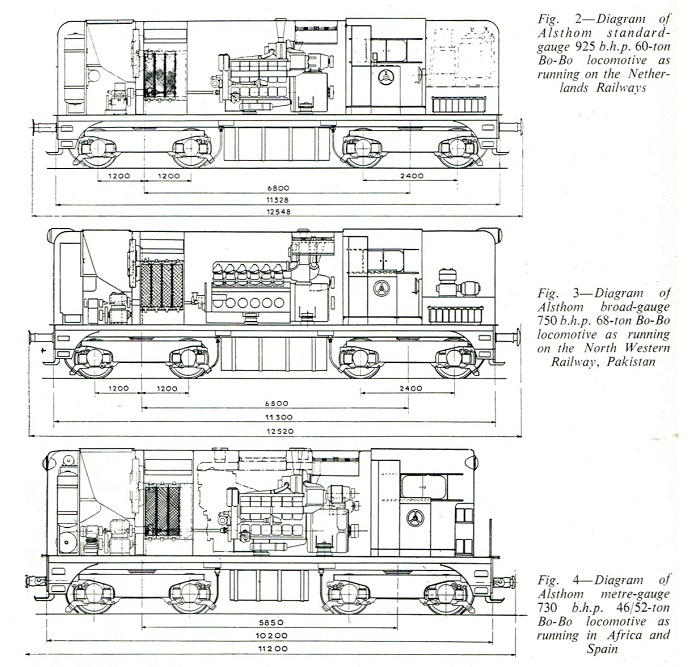

For future building, effectively all of the above were swept aside by the new Alsthom standard single-end cab Bo-Bo design. A full treatment of this design is out of scope here, but an overview is justified.

Alsthom's objective was to offer a standard range of Bo-Bo locomotives in the 600 to 1000 hp power covering gauges from metre to broad. It decided on two main variants, an end-cab unit for metre and Cape gauge applications, and a road-switcher for standard and broad gauge applications. Various SACM MGO and Pielstick engines were offered to meet specific power requirements.

The Outre-Mer systems would have been a major target for the metre gauge unit. A specific requirement for the latter was a base weight of 44 tonnes, for an 11-tonne axle loading, but with the possibility of ballasting to higher weights where required. That dictated that a relatively light, high-speed engine be chosen, rather than say a relatively heavy medium-speed unit such as the Sulzer 6LDA25. Whether the design was the result of an OFEROM commission is unknown, but it is almost certain that that organization was involved. On the other hand, Alsthom apparently was not aiming at SNCF requirements for the standard/broad gauge version; perhaps it saw that the Brissoneau & Lotz 040DE type was too entrenched to be worth challenging.

Simplicity and ease and speed of production was an overarching requirement. Alsthom claimed that the new design required only 1059 component parts as compared with 2993 in preceding Bo-Bo locomotives. Just which preceding design was not stated, but there is a fair chance that it was the Outre-Mer type.

As best I can determine, the first build of the new design for the Outre-Mer group of railways was for Madagascar. A fleet of 9 was ordered in 1953 October, with all shipped mid-1954. These were built to a weight of 46 tonnes, with an axle-loading of 11.5 tonnes, which evidently the Madagascar system could handle by then. They had SACM MGO V12S engines with a site gross rating of 670 hp at 1500 rev/min, as compared with the NTP rating of 730 hp.

The locomotive was of conventional design, with buffers and couplers mounted on the mainframe rather than on the bogies. The latter were of the latest Alsthom type with conical rubber pivots, and Watt linkage axlebox location with coil primary springs.

The electric transmission was for the most part conventional. Presumably as part of the overall simplicity, inherent characteristic load control was used. Interestingly, and I think unusually by the 1950s, Alsthom followed the original Lemp 1924 layout in using a combined exciter/auxiliary generator that was effectively in series with the battery. That avoided using two machines, whilst at the same time allowing the exciter to be of the lightly saturated type, with voltage more-or-less proportional to rotational speed, this aiding operation of the inherent characteristic process.

The type of power control (engine speed control) fitted is unknown. But the available information suggest that when equipped for multiple unit (MU) operation, the standard locomotive was fitted with a servomotor. That in turn suggests the Alsthom multinotch system with impulse control, in which the engine sped was set electrically by the servomotor. Working back from there, in the non-MU case, simple mechanical throttle control might have been used.

Maximum speed for the metre gauge standard variant was 70 km/h, the same as had applied to most of the preceding Outre-Mer locomotives. That was actually quite low for a diesel-electric line-service locomotive in the mid-1950s. It seems unlikely to have been either a running gear or traction motor rotational speed limit. Alternatively it might have been the expected maximum speed in typical service, or perhaps the speed at which unloading set in.

This Alsthom standard end-cab Bo-Bo design was subsequently adopted by most or all of the French Outre-Mer railway systems. As far as I know, the MGO V12 engine was the dominant type, although others might also have been used. Weights and other details varied by railway system. Acquisitions continued through the 1960s and perhaps into the 1970s, despite the fact that many of the roads also started using heavier and more powerful six-axle locomotives in that period. There were also various derivatives of the Alsthom standard locomotive, some used by the Outre-Mer roads.

![]()

Supplementary Information

Of the 16th and final example of the pre-Outre-Mer locomotive for Dakar-Niger, it was noted: "This had an improved traction motor design that incorporated one stage of field weakening. With this came a longer wheelbase bogie, 2.4 metres (7'10") rather than 2.0 metres (6'6.75"). This resulted in the one-hour tractive effort increasing to 16,000 lbf at 10 mile/h from 8400 lbf at 22 mile/h." Additional information strongly suggests that this was essentially the same bogie as used under the standard Outre-Mer design. It was said to have used a welded frame, a rubber pivot and Silentblocs for axle-location (these would have been at the ends of the Watt linkage rods.) All of these were characteristics of the Outre-Mer bogie.

Of those Outre-Mer bogies, it was also noted: "Whether the centre pivot was resiliently mounted is unknown, but it certainly looks as if it could have been". It is confirmed this was of the rubber type, although of an earlier design than the later conical pivot used on the Alsthom standard design.

In respect of the CF Tunisia Outre-Mer locomotives, it was noted: "Possibly these also had centrifugal filtration equipment". In fact they did, as probably as well as those built for Cameroun. A DRT 1949 September article referred to the 56 locomotives on order (which meant that all that were built were on order by then) and mentions that they were intended to be interchangeable amongst the Outre-Mer roads. This would imply that they all conformed to the same specification.

That article also mentioned that locomotive cost was an issue, with series production being one route to lower costs, and in some cases the use of mechanical rather than electric transmissions. That of course points to both Alsthom’s subsequent development of its standard locomotive and Oferom's dalliance with mechanical transmission.

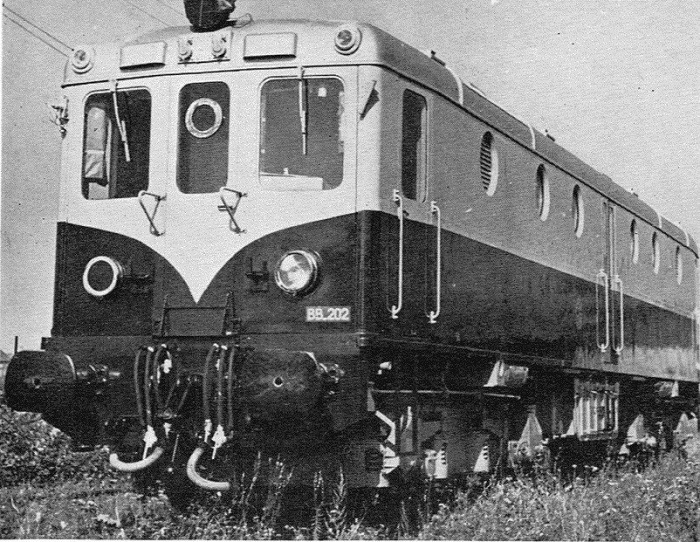

On the road numbers, of the Outre-Mer locomotives, this incomplete and unverified list is culled from various sources:

CF Dakar-Niger pre-Outre-Mer type: BB101 - BB116

RF Cameroun Outre-Mer type: BB201 - BB206

OC Benin-Niger Renault 5040 DM: BB301 - BB305

CF Conakry-Niger Renault 5044 DH: BB201 - BB213

CF Abidjan-Niger Alsthom Twin-Engine: 601 - 605

These details be treated with some caution and checked against known authoritative sources.

This Outre-Mer locomotive group is an interesting study of very early dieselization in less developed parts of the world, with relatively small locomotives designed to fit the railway systems as they were at a time when track upgrading, etc., to accommodate larger units was out of reach. It also illustrates the difficulties of co-ordinating the sometimes conflicting desiderata of standardization, supplier diversity, technology diversity and cost reduction. One may see that Sulzer's early and significant involvement in diesel traction was a major facilitating feature for the initial Outre-Mer locomotives, but that this engine maker was edged out as lower-cost options of French indigenous design became available.

![]()

CFA (Algeria) 060YDA Class

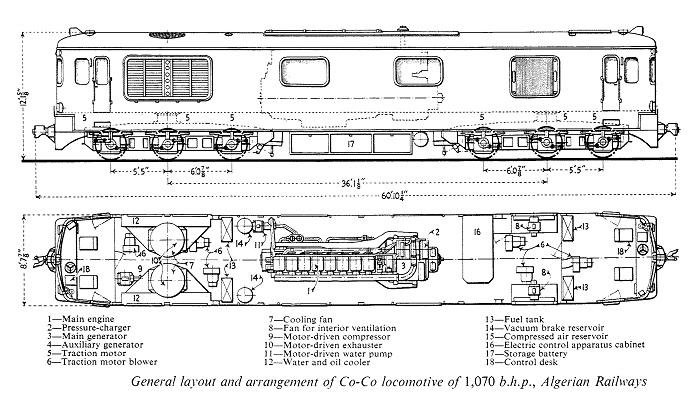

The 060YDA class comprised 10 1055 mm gauge locomotives built by De Dietrich for CFA and equipped with Sulzer 8LDA25 engines and Alsthom electrical equipment.

The order was recorded in Diesel Railway Traction (DRT) 1951 July, and the locomotives are understood to have been delivered during 1954.

The 060YDA was a 72 tonne Co-Co unit with a 12 tonne axle loading. In a broad sense it could be considered to have been an extrapolation of the Outre-Mer design to use the 8LDA25 rather than the 6LDA25 engine, and with 6 rather than 4 axles, for a slightly lower axle loading. But powerplant and some details aside, it was not essentially homologous with the Outre-Mer design.

In fact, the homologous extrapolation had already been done with the RSR, Thailand 561 class. This used the 8LDA25 engine on the A1A-A1A wheel arrangement, and was directly derived from the RSR 651 class, a Bo-Bo design using the 6LDA25 engine. These were both Sulzer designs, with electrical equipment supplied by Oerlikon and mechanical parts and assembly by Henschel.

A significant feature of the 060YDA was that it was extraordinarily long for a CMT-gauge locomotive in the 1000 hp class. This is apparent from the diagram:

Length over headstocks was not given, but from the length over couplers of 60'10.25" (18.55 metres) one may estimate it to have been approximately 57 ft. This was soon exceeded by the 1500 hp NZR Df class, also from 1954, at 58'0", but this had 10 axles. As best I can determine, the first conventional double-bogie CMT-gauge diesel locomotive to exceed the length of the 060YDA was the Ghana 1401 class of 1959, a 1425 hp Henschel-EMD design that was around 61 ft over headstocks. In this case the extra length was needed to allow enough room to accommodate the engine-generator set in a frame depression between the bogies.

The 060YDA length may be compared with other Sulzer 8LDA25-engined locomotives. The RSR 561 was 47 ft over headstocks, and the JNR DF50 (which also mounted a train-heating boiler) was around 51 ft. Both of these were six-axle locomotives. The JNR DD50, with four axles, was quite short at around 36 ft.

Possibly the length of the 060YDA can be explained by the fact that De Dietrich was essentially a railcar builder, and so was accustomed to building relatively long structures. Its passenger vehicle activities extended to the fourgon type, of which it had built some for the CFA standard gauge network in 1951, powered by a pair of Sulzer 6LDA25 engines.

The 060YDA had a family resemblance to these, and its 72 tonnes on a 57 ft length points to some form of relatively light weight construction.

It differed from the Outre-Mer type in that the couplers and buffers were mounted on the mainframe headstocks, and not on the bogies. The latter were of the rigid bolster type, presumably deemed to be satisfactory for the maximum service speed of 85 km/h. The bogie frame was of the welded form with girder-type sideframes. Like the Outre-Mer type, it had the Alsthom Watt linkage type of axlebox location, which also would have provided some lateral compliance. Primary suspension was by overhung leaf springs with series coil springs at their anchor points. The outer and centre springs were connected by an equalizing bar. Equalizing just two of the three bogie axles was not so unusual, but less common was the fact that the leaf springs were attached to the equalizing bar via series coil springs. Perhaps absent any secondary springing, the intent was to maximize primary spring performance.

Although the axle-box location was of Alsthom design, perhaps the rest of the bogie was influenced by Sulzer. The structure and suspension was very similar to that which had been used for the RSR 561 class, except that the latter had conventional pedestals and also had the couplers mounted on the bogies. Something very similar to that Sulzer bogie design was also used on the later RSR 611 class, built by Hitachi. In fact, although that locomotive was to some extent derived from the Hitachi DF90 prototype, it may also be seen to have been influenced by the Sulzer 561 class design. The 611 had a MAN engine, and as an aside it may be noted that it was not the first time that there was some kind of a connection between Sulzer and MAN. The SNCF 262AD1 and 262BD1 case was an early example, and of course the JNR DF50 used both Sulzer and MAN engines. The VR (Finland) Hr16, MAN-engined, was a relative of the Sulzer-engined CFR (Roumania) 060DA.

The Sulzer 8LDA25 engine as used in the 060YDA had a sea-level continuous rating of 1070 hp at 800 rev/min, with a site rating of 960 hp at the same speed. Evidently in this application, the one-hour rating was not used. The main generator and overhung auxiliary generator were mounted as a unit with the engine. How the six traction motors were connected is unknown, but 6P seems likely. The Alsthom antishunt system of field weakening was used, meaning that the motors each had two field windings. How the antishunt windings were excited is not apparent from the available information, but the drawing does not show a separate antishunt exciter overhung from the auxiliary generator.

Unlike the Outre-mer type, the 060YDA does not appear to have been equipped for MU operation. The control system would certainly have been according to Sulzer requirements, including servo-regulator load control. Whether it used the older Sulzer 10-notch system, as used on the Outre-Mer type and the above-mentioned CFA fourgons, or the newer pneumatic system is unknown, although by the time the locomotives were built, the latter was extant, including in French practice. It had been used, for example, on the SNCF 040DE of 1953. As is fairly well known, Sulzer put quite a bit of effort into the development of diesel-electric control systems, with particular attention to the needs of 'overseas' railway systems where often adhesive weight was limited in relation to power, and fuel economy was paramount. Less well-know is the extent of its influence on British practice. Both of BR's initial diesel-electric control and MU standards, electromagnetic (later 'red circle') and electropneumatic (later 'blue star') may be traced back to original Sulzer systems.

All of the auxiliaries, including the radiator fans, were electrically driven. Each traction motor had its own motor-driven blower, in that sense resembling the Outre-Mer type. However, unlike the latter, the blowers were not mounted on the bogie sideframes, but within the locomotive body, at points convenient for the use of short ducting to the motors.

The 060YDA was vacuum-braked, with motor-driven exhausters, and large vertical brake cylinders mounted on the inner ends of the bogies. That was different to the Outre-Mer type, which was air-braked itself but equipped to haul vacuum-braked trains. The latter combination was more common with diesel locomotives on vacuum-braked railway systems, but the 'all-vacuum' approach had its adherents, amongst whom appeared to the British Crown Agents.

Continuous tractive effort was 10,000 kgf at 15 km/h (22,000 lbf at 9.35 mile/h). Thus the MCS was quite low for a CMT-gauge diesel-electric locomotive of its time, and ensured that it was suitable for operation on the 2.5% (1 in 40) grades encountered in its operating area. Starting tractive effort was stated as being above 17,000 kgf (38,000 lbf).

The 060YDA was a locomotive of the Outre-Mer period, if not an immediate relative to the eponymous type. As with the central group of Outre-Mer locomotive users, CFA went on to use the later Alsthom standard single-frame tribo models for its 1055 mm gauge network.

Additional note: With regard to the locomotive length the scaling from the drawing suggests the 060YDA length over headstocks as 57'3'. That was longer than passenger stock in some countries.

The Esslingen metre-gauge 1900 hp C-C diesel-hydraulics built for service in Brasil (Leopoldina and Rio Grande do Sul) at about the same time were close, at 56'5' over headstocks, but within this length was accommodated two 8-cylinder in-line MAN 22/30 engines which would not have been much shorter overall, if at all, than the Sulzer 8LDA25.

As mentioned, the Henschel-EMD TT12 for Ghana was a subsequent one-off CMT-gauge double bogie design that was longer still. Of the 'standard' CMT-gauge models, the EMD GT22C of the later 1960s came close at 57'0', and the GT26MC (as built for SAR from 1971) exceeded it, at 59'6', as did the CEM BB-BB of 1969, at 18 metres (59'1'). But the latter two were around three times or so the power of the 060YDA.

The 060YDA was also longer than any of the CMT-gauge 1-Co-Co-1 models, which did not go beyond 56'0'.

![]()

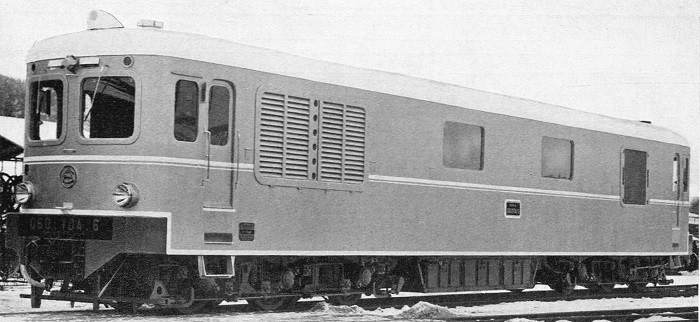

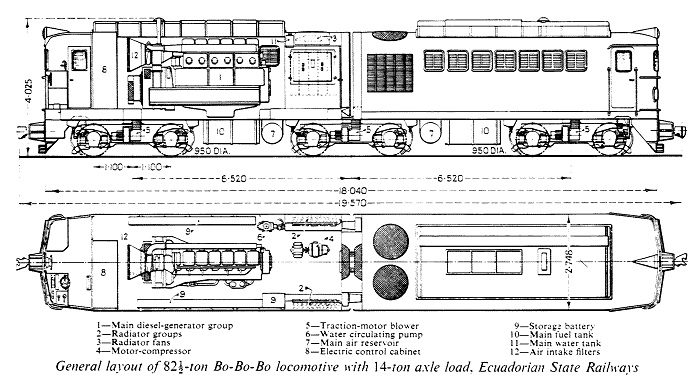

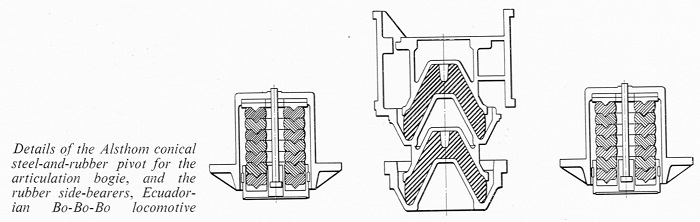

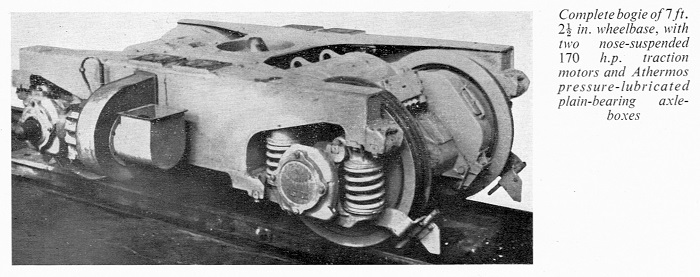

Ecuador BBB151 Series

The five locomotives in this series were built by Alsthom in 1957, against a 1954 order (recorded in DRT 1955 January).

They embodied elements of both the recent Alsthom standard design, such as the bogies with conical rubber pivots, and of the definitive Outre-Mer type, such as the Sulzer 6LDA25 powerplants. Appearance-wise they had a family resemblance to the Outre-Mer type.

More than that, they were the first, and as it happened the last, diesel-electric locomotive design to use the articulated-body triple-bogie (tribo) form. At this stage it is worth digressing into a little tribo history, which must necessarily include some references to electric locomotives.

The dominant tribo form is the single-frame type, in which the centre bogie is allowed significant and relatively free lateral movement by various means, with the outer bogies doing the guiding around curves. Flexibility to traverse vertical curves is provided by having relatively compliant primary and/or secondary suspension.

The first single-frame tribo locomotives, and in fact the first tribo locomotives of any kind, were a group of standard gauge Bo+Bo+Bo 3 kV DC electrics built by GE for the Ferrocarril Mexicano in 1925. Consistent with practice of the time, it was an articulated bogie design. As best I can determine from the information available, only the outer bogies had pivots, the centre bogie being loaded from the mainframe by a sliding device, but located by its articulated connections to the outer bogies. The only other known single-frame tribo with articulated bogies was the Co+Bo+Co diesel-electric design built by GE, initially for IRCA, Guatemala in 1950.

The first single-frame tribo diesel(-electric) locomotives were the metre-gauge Bo-Bo-Bo group built by Alsthom for service in Madagascar from 1939, and described earlier in this series. One could say that ongoing quantity use of the single-frame tribo form started with its adoption by JNR (Japan) for its initial production standard diesel-electric locomotive, the Bo-Bo-Bo DF50 of 1957. JNR went on to use it for many of its AC and DC electric locomotives, and for some diesel-hydraulic and later diesel-electric locomotives. It also made use of the unpowered centre bogie, as in the Bo-2-Bo and B-2-B types. This idea had been pioneered by GE in 1953 with a Co-2-Co build for Indonesia. At some stage - in the mid-1960s I think, the Japanese industry adopted the roller frame form of lateral motion enabler for the centre bogie, usually in combination with its characteristic outside flexicoil secondary suspension. The roller frame had been pioneered by Westinghouse for its 1950 Bo-Bo-Bo-Bo gas turbine-electric prototype, and was used again on the Pennsy E2c Bo-Bo-Bo prototype rectifier AC electric locomotive of 1952.

The articulated-body tribo type was originated by FS, Italy, in 1940, with its Bo-Bo-Bo E636 3 kV DC electric class. Whilst new to locomotive practice, the articulated body form had been used previously for passenger stock. Evidently FS wanted a laterally and vertically flexible successor to its E626 class. The latter was of the rigid frame Bo-Bo-Bo form, in which the two centre axles were mounted in the mainframe, and not in a bogie, with the outer bogies acting as powered pilot trucks. Notionally it was a 2-Bo-2 type with powered trucks. For its somewhat curvaceous routes, FS also preferred the shorter wheelbase provided by two-axle bogies. The articulated-body Bo-Bo-Bo form provided this, as well as lateral and vertical flexibility with minimum superstructure overthrow on curves. The E636 also presaged some of the features that went into the 'modern' electric locomotive of which the BLS Ae4/4 is said to have been the epoch marker. It was an all-adhesion design with independent, lateral motion bogies with each axle having its own motor, and capable of reasonably high speeds. I suppose that the Ae4/4 was differentiated by its very high power-per-axle, 1000 hp, whereas the E636 was about half of this. FS went on to acquire several hundred of the articulated-body Bo-Bo-Bo electric locomotives in several series, finally switching to the single-frame tribo form in 1979.

Outside of FS, the articulated-body tribo found few applications. New Zealand Railways used it for its seven Cape gauge Ew class 1.5 kV DC electrics of 1952, built by EE. The articulated-body tribo entered the diesel realm in 1953, when Krupp built four rather odd centre-cab diesel-hydraulic prototypes, three standard gauge for CFA, Algeria and one metre gauge for Vale Rio Doce, Brasil. These were twin-engined with the Krupp one-converter-per-axle form of transmission, and so had the Bo-Bo-Bo wheel arrangement.

Perhaps a subset was the rare semi-articulated body tribo, in which the two body sections may move relative to each other only on the pitch axis, in order to help negotiate vertical curves. They are fixed in respect of the yaw axis, so that from the viewpoint of negotiating horizontal curves, the locomotive behaves like a single-frame tribo and so requires extended lateral motion capability for the centre bogie. The first build was the Ge6/6 II, 11 kV 16.66 Hz single-phase electric for the metre-gauge Rhaetian Railway (RhB) in Switzerland c.1958. One imagines that on its steeply-graded mountain routes, the added vertical curvability conferred by the semi-articulated body was highly desirable. Then 2 (of the 4) SBB Re6/6 prototypes were semi-articulated, the other 2 being of the single-frame tribo type. The latter proved satisfactory, and the production fleet was built that way.

Finally, the only really asymmetrical tribo form was that of the CEM (France) B-BB diesel-electric type, built for RAN (Abidjan-Niger) from 1971. This had a span bolster B-B assembly from the CEM BB-BB design at one end, and a single B bogie at the other. The bogies were of the monomoteur type, so it was a B-B-B. I said really asymmetrical because the JNR DF50 was slightly so, with the bogie centres distances being unequal, with the centre bogie thus offset a little from the locomotive centre. I imagine that this was done to obtain the correct weight distribution, and as far as I know, it was a feature not otherwise used.

All of that puts the Ecuador BBB151 in context as rather a 'rare bird'. And it meant that Alsthom had built both single-frame and articulated-body tribo diesel-electric types. At about the same time as it was building the Ecuador locomotives it was also developing a new metre-gauge single-frame tribo diesel-electric for Burma, derived from its new standard Bo-Bo design. This new Bo-Bo-Bo type and its derivatives remained in the Alsthom export range for many years.

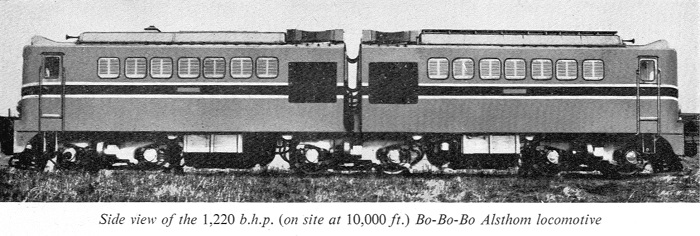

A logical question is why was the twin-engined, articulated-body design chosen for the Ecuador application. I haven't seen any definitive comment on this, so it is necessary to speculate somewhat. Firstly, the operating conditions involved gradients of up to 5.5% (1 in 18), curves down to 60 metres radius, and a maximum altitude of 3600 metres (11,800 ft). These suggested a locomotive that had relatively short wheelbase bogies and was very flexible horizontally, and reasonably flexible vertically. Secondly, to meet the haulage requirements at altitude, a turbocharged diesel engine with a sea-level output of at least 1500 hp was required. The axle loading had to be no more than 15 tonnes, and preferably lower. In practice that meant 6 axles rather than 4, so Bo-Bo-Bo would have been an obvious choice of wheel arrangement.

I think we may assume that Alsthom would have preferred to use a French-built engine, and given that French finance was involved, such may have been mandatory. At the time the SACM MGO range did not extend upwards to 1500 hp. From the CCM-Sulzer range, the 8LDA28 was probably a little short of the power target at the time, although by the end of the 1950s it was available at 1550 hp. The 12LDA28 at 2000 hp would have been overkill, and anyway it almost certainly too heavy to fit in a 90-tonne maximum locomotive, and probably too bulky in what would be a fairly small profile unit. There was no 12LDA25, but a pair of 6LDA25 (very little, if any heavier than a notional 12LDA25) could meet the site power requirements, besides being a powerplant with which Alsthom was very familiar and with which it had acquired quite significant experience in overseas applications. Not only that, but Alsthom already had matching main generators and other components.

Once the twin-engined arrangement had been chosen, implying a largely symmetrical equipment layout, then coupled with the tribo choice it was probably but a small step to the articulated-body form, which, which would have provided maximum flexibility both vertically and horizontally, and without the need to provide for extended lateral motion for the centre bogie. A reasonable assessment is that unusual though it may have been, the BBB151 was a logical solution to the problem given the constraints, and one that was low risk in that it was based largely upon proven components.

A very rough conceptual approach to the BBB151 would be to take a pair of the Outre-Mer type, chop-off one end (cab and half the bogie) over the bogie centre, then join the two halves, rigidly at the bogie and flexibly between the bodies. Then fit updated bogies, and a dynamic braking system. Obviously, what was done was rather more sophisticated than that, and this was the result:

Bogie centres for the BBB151, at 6.52 metres, were somewhat shorter than those for the Outre-Mer type, at 7.2 metres, so that it was somewhat 'compressed' as compared with a back-to-back 'chopped' Outre-Mer couple. Weight was 84 tonnes, with an axle loading of 14 tonnes, so easily within the 15 tonnes maximum originally specified.

The bogies followed the then-new Alsthom standard pattern, with welded box frames, Watt linkage axle location, coil primary springs and conical rubber pivots. The centre bogie had a double pivot arrangement in order to accommodate the two body sections.

The Sulzer 6LDA25 engines had a UIC rating of 760 hp at 800 rev/min. The site rating, at 10,200 ft (3100 metres) altitude and 25C, was 610 hp at 800 rev/min, which also happened to be the site rating of the Outre-Mer locomotives. Thus the combined site gross power was 1220 hp.

The engines were mounted in unit with Alsthom main and overhung auxiliary generators. In normal operation, the two main generators were connected in series, with the six traction motors in parallel (6P) across the combined output. Operation from one power unit, with the motors in 6P, was possible. These locomotives did not have the Alsthom anti-shunt system of field weakening. Rather they had one stage, 50%, of conventional field weakening by diversion, selected manually but with automatic reversion.

The control and excitation system was apparently a mix of old and new. According to one source, they had 10-step pneumatic control of engine speed. According to another, they had 12-step control from an Alsthom pneumatic servo-motor. The latter was a feature of the standard range when it was equipped for MU operation. At least in later iterations, such as when it was used in the CC2400, it allowed impulse control as well as the follow-up type. How it was used in the BBB151 is unknown, but my guess is that it would have been follow-up.

My interpretation from combination of the information from the two sources is that the engines were equipped with the newer, pneumatic speed control version of the Sulzer governor, and that the air pressure input to this was regulated in 10 steps by the servo-motor. Additionally, there were two fixed excitation starting notches.

Naturally they were equipped with servo load regulator main generator field control in the Sulzer manner. But additionally, they had the Alsthom variable voltage combined auxiliary generator and exciter, as used on the standard models and which was normally found with the inherent characteristic form of load control. How the two were combined is unknown, but perhaps the load regulator served simply as a final trim, with the exciter alone getting the main generator field strength 'in the ballpark' as it were. That said, the main generators had separate and shunt field windings, and it was not unknown for some Sulzer systems to include control of the shunt field strength. It is not apparent that the BBB151 was equipped for multiple unit operation.

The BBB151 was equipped with dynamic (rheostatic) braking, not surprising considering that its operating territory included long and steep descents. This I think was the first such installation on a diesel-electric locomotive by Alsthom, although it became reasonably common on subsequent export locomotives. Dynamic braking was initiated and controlled by turning the control wheel in the opposite direction to that used for power control. This was a reasonably fool proof approach, and avoided the problems that could occur (e.g. the Wadenswil disaster) when for example the power control handle or wheel also doubled as the dynamic brake control. I imagine that the driver's commands went to the servomotor which then directly controlled dynamic brake excitation - at least that was the way it was done in the CC2400. The dynamic brake resistances were roof-mounted, and cooled by airflow from the main cooling group fans. Given that the fans were electrically driven, it is possible that during dynamic braking, they were switched from auxiliary generator to regenerated current supply.

All of the auxiliaries were electrically operated, as had been the case with the Outre-Mer type. Alsthom had made the change to largely mechanically operated auxiliaries with its standard model, in part to save weight and cost, and to simplify maintenance in that commutator electrical machines were sometimes thought to be potentially troublesome. But then belt drives for example were not universally liked. The BB151 emulated the Outre-Mer type in one respect, in that one traction motor blower for each motor, and these were mounted on the outsides of the bogie frames.

Unsurprisingly, considering the altitude at which it operated, the Ecuador State Railway was air-braked, so the BBB151 was fitted with the usual straight and automatic air brake equipment, with lockout of the locomotive brakes (from an automatic application) when dynamic braking was operative.

Continuous tractive effort was quoted as 30,900 lbf at 10.9 mile/h (14,000 kgf at 17.5 km/h), so the MCS was relatively low. Starting tractive effort was 50,800 lbf (23,000 kgf), which was 27.5% adhesion. So this was likely the equipment-limited number. Maximum speed was 43.5 mile/h (70 km/h), the same as for the Outre-Mer type.

With a UIC output of 1520 hp, the BB151 fell into the upper range for CMT-gauge diesel locomotives of the time, say 1500 hp and upwards on a UIC basis. There were not so many examples extant at the time that the BBB151 was built. English Electric had built the QR 1200 (1500 hp, 90 long tons (LT), 15 LT axle-loading, the NZR Df (1500 hp, 108 LT, 12 LT AL and the RR DE2 (2000 hp, 113 LT, 15 LT AL). GE had recently released the U18C model (2000 hp, 90 LT, 15 LT AL), Esslingen had built a diesel-hydraulic for Brasil (1900 hp, 78 LT, 13 LT AL). So had Krupp (2000 hp, 96 LT, 16 LT AL) but this was not a credible contender. The EMD G16 and Alco DL541 were still in the future, and although Alco offered the DL500 for metre gauge and upwards, it was really too big for the CMT case and did not find any such applications. The BB151 (1520 hp, 82.5 LT, 13.75 LT AL) compared reasonably well with the group as a whole, although the fact that it had two engines where the other diesel-electrics had one would generally be regarded as a disadvantage. In the mid-1950s, diesel-hydraulic locomotives in this power range necessarily had two engines, as the available hydraulic transmissions could not absorb much over 1000 hp. In that sense an articulated-body diesel-hydraulic locomotive was not at a disadvantage to the single-frame type, as either way, at 1500 hp and above, two engines were required. This situation did not change until c.1960, when higher-capacity transmissions became available.

Thus the BBB151 was essentially a special-purpose locomotive. The Ecuador system did not need any more after the initial 5, and no other system at the time had a combination of circumstances that pointed to the BBB151 or something similar as being a logical solution. As engines were developed to higher specific outputs, single powerplants were easily able to address the need for 2000 hp or more at lowish axle loadings on CMT-gauge systems. Single powerplants could be fitted on a single-frame tribo chassis, so that where a tribo wheel arrangement was otherwise desirable, that was the form it would take. Alsthom developed a single-frame tribo design derived from its standard Bo-Bo model at about the same time that it was working on the BBB151, and this became the basis of its future tribo sales.

Looking at articulated-body tribo diesel locomotives generally, South American operators had 6 of the 9 built, namely the single Krupp diesel-hydraulic for Brasil and the 5 Alsthoms for Ecuador.

Taking a broader view of all tribo types across Latin America, Guatemala was the first operator with the GE single-frame Co+Bo+Co design, also operated in Columbia. Then came the Brasilian and Ecuadorian articulated-body types. In 1968, the Bolivian Railway started its fleet of Hitachi/Mitsubishi single-frame tribos, based upon the JNR DF50. In the 1990s, Ecuador acquired some Alsthom AD24 single-frame tribo models.

Virtually all railway systems who initially acquired the articulated-body tribo type eventually turned to the single-frame type. As best I can determine, CFA, Algeria was the first to field both types, albeit on different gauges (assuming that its Krupp diesel-hydraulics were still in service when the first of the Alsthom 060YDB class arrived in 1958), followed by NZR, then FS, Italy, and then Ecuador. Vale Rio Doce, Brasil, was the exception.

![]()

Page added March 15th 2020.