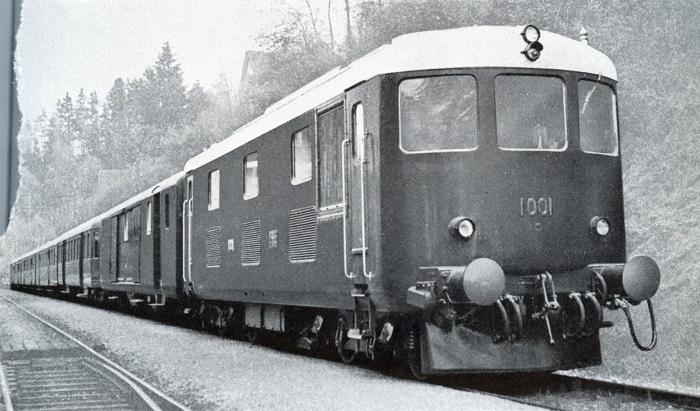

During 1939 Swiss Federal Railways took delivery of two 1,200hp Bo-Bo diesel-electric locomotives for use on secondary routes, primarily for the haulage of light trains on non-electrified branch lines. The specific requirement was for the haulage of trains in the 150 to 200 tonne range on grades up to 1.2%, with a maximum speed of 110 km/h. The order was placed by SBB at the end of 1937 December.

The locomotives were equipped with engines by Sulzer, electrical equipment by Brown Boveri (BBC), and mechanical parts by SLM. There appears to be no evidence of a prime contractor. However SBB would have been well-accustomed to working with all three participants, who in turn would have been used to working together on SBB projects.

The Am4/4 was fitted with the Sulzer 8LDA28 engine, with an output of 1200 hp at 750 rev/min (also quoted as 1100hp and 1050 at 660rpm. It is uncertain abut the continuous rating for the early version of this engine, but 1060 hp at 700 rev/min would be a reasonable estimate.

The heating alternator was of 100 kW capacity, providing 1000 volts at about 50 Hz (but ranging between, 16.67 Hz & 60 Hz with engine rotational speed between 425 rpm and 750 rpm), single-phase, which was the SBB norm for train heating. It is not known at what engine speed the frequency was 16.67 Hz, but as the frequency would vary with engine speed, the range would have to be set so that the lower and upper limits were what the passenger stock equipment could handle. For heating alone, a 'frequency wild' situation was probably acceptable, but with auxiliary loads, e.g. car lighting, involving say transformers and motor-generators, then there would be frequency limits for acceptable performance. The alternator was either a 6- or 8-pole machine, most likely the latter.

The heating alternator was excited from the 155-volt auxiliary supply, via a rotary machine referred to as a 'voltage depressor'. The latter was driven by the same motor as used for the 36-volt control supply generator. Effectively the voltage depressor was a voltage booster in reverse, subtracting from the 155-volt auxiliary supply to provide an excitation voltage range of 55 to 130 volts. The (low current) depressor field was controlled by a small voltage regulator so that the alternator output was maintained at 1000 volts across the engine operating speed range.

The four BBC self-ventilated traction motors with BBC quill and spring type drives were connected parallel without any field weakening. They were bogie-mounted with BBC flexible disc drives. The gear ratio was 5.37:1, and the driving wheel diameter was 1040 mm (41 inches).

Power control was by the Sulzer-BBC system using a 9-step power controller, 4 engine speeds and most likely 4 load control set points. Notches 1 to 3 were at minimum engine speed, 450-430 rev/min, notches 4, 5 and 6 were at 570-560 rev/min, notches 7 and 8 at 670-660 rev/min, and notch 9 at maximum engine speed, 750 rev/min. At least notches 5 through 9 would have been of the load control type. Notch 9 would have corresponded to the one hour rating, and notch 8 to the continuous rating. This may have been the last new Sulzer-engined design to use the Sulzer-BBC system before the move to the all-Sulzer system with 8 stepped engine speeds. In this case, the BBC servo-regulator had 4 solenoids for torque (load) setting. This would appear to have been an advance on the control system of the CFR DE241, which had 8 notches of which 4 were of the load control type. However, Sulzer was inclined to tailor control systems to suit individual locomotives rather than to apply a single standard, so the difference may well have been one of 'horses for courses' rather than design evolution.

The one-hour tractive effort was 9,600 lbf at 31.5 mile/h, and the continuous tractive effort was 6,800 lbf at 45 mile/h. Also, the maximum starting tractive effort was 22,000 lbf (10,000 kgf). Against the service weight of 65.5 tonnes, that was about 15% adhesion, so it was evidently the equipment limited number.

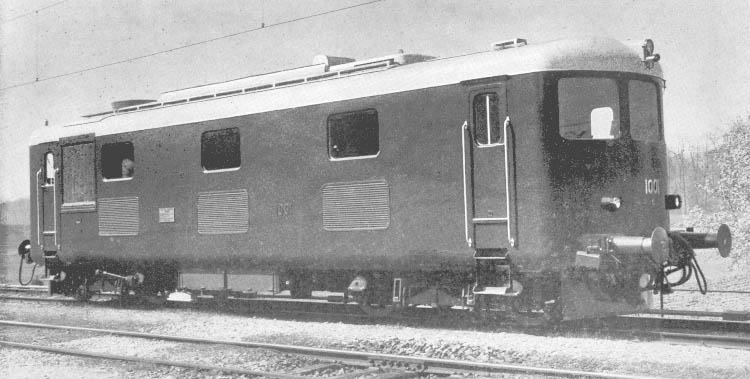

Built by SLM, with electrical equipment by Brown Boveri Company and powered by a Sulzer 8LDA28 in line power unit, the locomotive weighed only 65.5 tons with a maximum speed of 68mph (110km/h). A dc traction generator and train heating alternator were carried on the same frame running at 750rpm. They were equipped for multiple unit operation, allowing them to be used on sleeper trains.

Locomotive No.1001 made its first journey on April 20th 1939 travelling from Munchenstein to Winterthur. Trials followed on the Winterthur - Schaffhausen line. From May 6th until the end of October 1939 the locomotive was on display in the Swiss National Exhibition in Zurich.

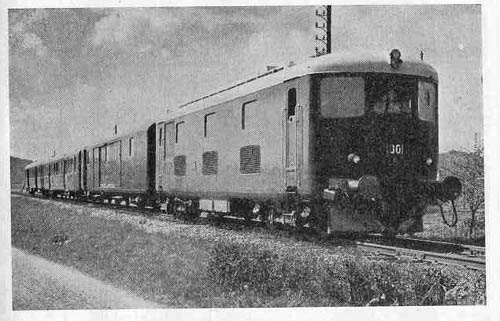

Locomotive No.1002 made a test run on July 17th 1939 with a Winterthur - Geneva roundtrip, a total train weight of 180 tons which included a dynamometer car. On August 18th a test run with a dynamometer car was made to determine the heating conditions of the electrical equipment and provide data for determining the loading regulations for railway staff. The total train weight was 266 tons with the test run measuring about 340km.

From these measurements the following were authorised:

Normal trailer load = 150 tons (with locomotive = 215 tons) on gradients of 12% to existing steam timetable

Exceptional trailer load = 200 tons (with locomotive = 265 tons) on gradients of 12% to existing steam timetable.

During 1963 the two locomotives were regeared resulting in the maximum speed reduced to 75km/h, with an increased tractive effort.

They were later renumbered 18451 & 18452 (Class BM 4/4 II), up to 1976 they had covered 770,000 & 910,000 miles respectively. 18451 is preserved whilst 18452 was scrapped during 1990.

1001

SLM 3691

Accepted May 2nd 1939

Renumbered 18451 1959

Released from R3 overhaul July 12th 1963 from then Bm 4/4 II

Now museum locomotive based at Olten

1002

SLM 3692

Accepted August 14th 1939

Renumbered 18452 1959

Released from R3 overhaul December 4th 1964 from then Bm 4/4 II

Retired July 31st 1990 and scrapped

General Details

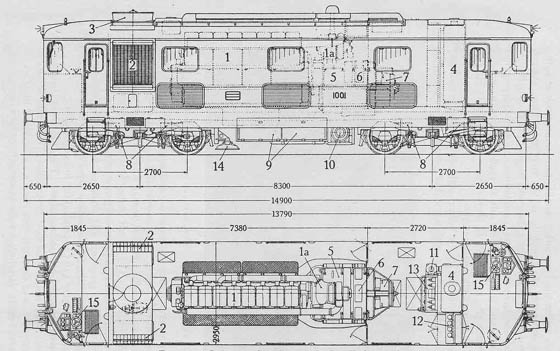

Gauge: 1,435mm

Minimum curve radius: 80m radius at 3km/h; 300m radius up to 70km/h

Length over buffers: 14,900mm

Overall wheel base: 10,950mm

Distance between bogie centers: 8,300mm

Bogie wheel base: 2,700mm

Diameter of driving wheels: 1,040mm

Width of body: 2,950mm

Maximum height above rail: 3,995mm

Maximum speed: 110 km/h

Mechanical parts including compressor: 26.2 tons

Diesel Engine: 14.1 tons

Electrical equipment: 18.5 tons

Starting battery: 1.8 tons

Miscellaneous equipment, sand, driver: 1.5 tons

Supplies - fuel, lube oil and cooling water: 3.4 tons

Total weight: 65.5 tons

![]()

Other Swiss Sulzer powered diesels:

CFF 1501 - 1504, Swiss Rail & Luggage vehicles

![]()

Page added October 27th 2003.

Last updated November 3rd 2023.

Return to Sulzer page

Return to site menu