The metre gauge Royal State Railways of Siam took early steps to dieselise their railways due to the serious inroads being made into the nation's lumber supplies by their fleet of wood burning steam locomotives. Despite the necessity of now having to import oil for the new diesels, several diesel orders were placed, the first in 1927 for two 180hp diesel mechanicals built by the Swiss Locomotive Co for shunting and local traffic work around Bangkok. Further orders followed in 1931/32 including one 1,600hp heavy goods locomotive, six 1,000hp express passenger locomotives and the first of three orders for Sulzer powered locomotives as follows:

1931/32 six 450hp machines, # 501 - 506

1945/46 four 735hp machines, # 651 - 654

1950/51 three 960hp machines, #561 - 563

Additionally six 150hp railcars were purchased. All the orders upto 1932 were placed under requirements laid down by the CME Mr H A K Zachariae, details of the designs were worked out by the builders - Frichs & Sulzer Brothers.

The 1931/32 build were for use on the northern Bangkok - Pitsanulok / Chiengmai lines and the southern Bangkok - Hua Hin line.

The 1945/46 build were for use on the Bangkok - Singapore line (750 miles) and the Bangkok - Chiengmai line (465 miles).

The 1950/51 build were for use on Bangkok - Padang Besar line (625 miles and the Bangkok - Chiengmai line (465 miles).

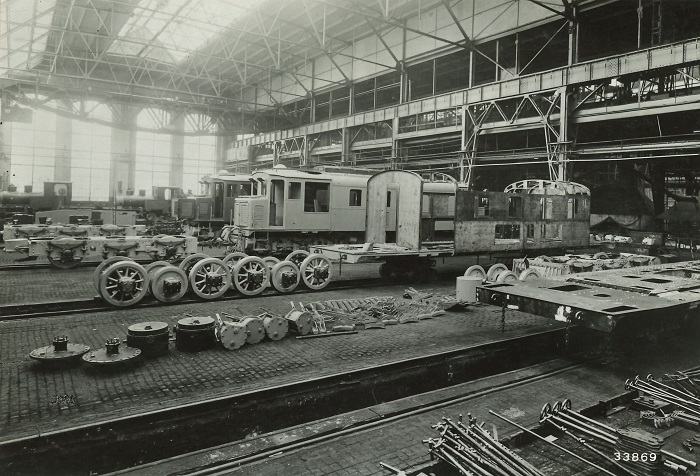

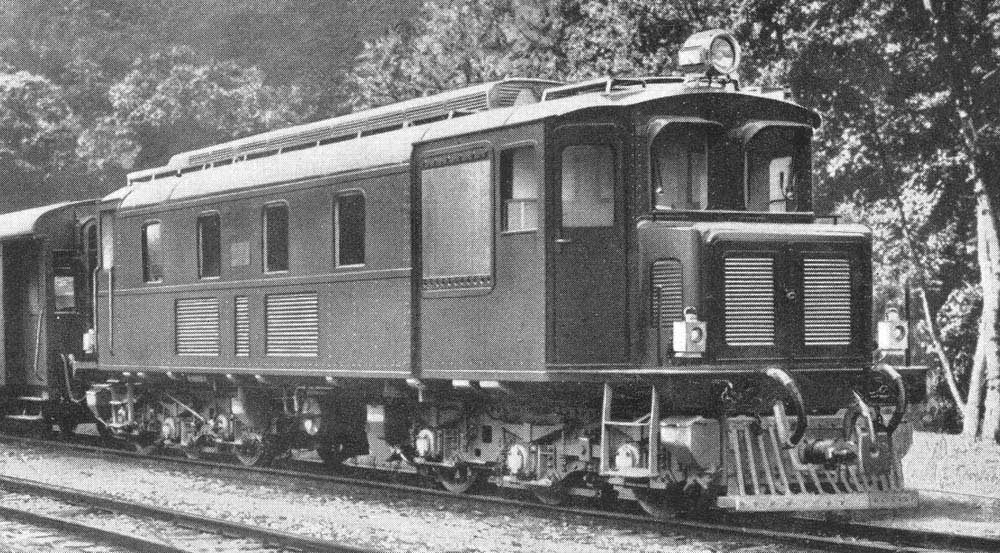

In 1930 six 450hp diesel-electric locomotives were ordered from Sulzer Brothers, with the first of them undergoing tests in Switzerland during the summer of 1931. Design specifications were to the order of Sulzer Brothers, the mechanical portions were constructed by Henschel & Sohn AG, Kassel (works numbers 21825 - 21830) and electrical equipment supplied by Ateliers de Construction Oerlikon.

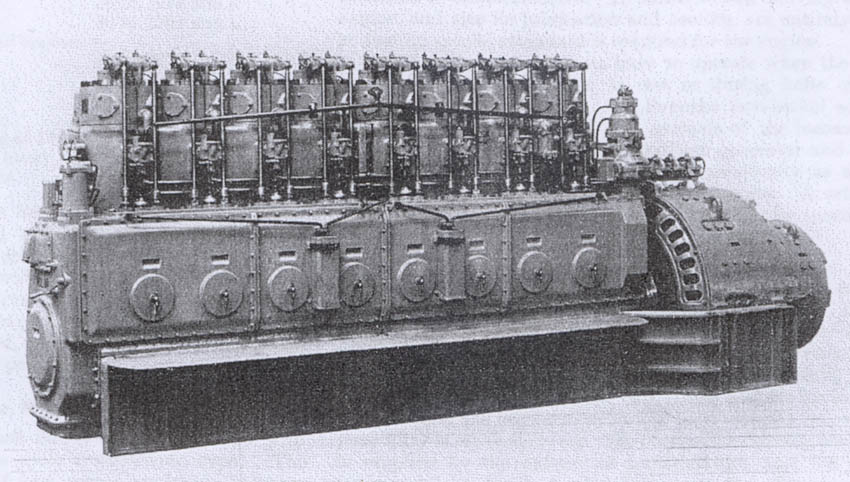

The Sulzer engine was an eight cylinder four stroke cycle trunk-piston type (8LV25) with a maximum output of 450hp at 700rpm. Cylinder dimensions were 250mm x 310mm being cast in two blocks of four bolted together to form one rigid block. The light main frame is of cast steel. The connecting rods were of chromium-nickel steel, the uncooled pistons were aluminium. Operation of the engine was by direct airless injection of fuel on the precombustion chamber principal which required low injection pressure and fairly large nozzle holes. Each cylinder had its own readily accessible fuel pump, situated between the pushrods of the inlet & exhaust valves, the pumps were driven off the main camshaft. Fuel delivery was controlled by a centrifugal governor set to keep the engine running at a constant speed.

Starting the engine was by means of motoring the main generator from a battery. The main generator was self ventilated and provided power to four series-wound nose suspended traction motors worked in parallel, also self ventilated, using reduction gearing to transmit power to the wheels. The auxiliary generator was directly coupled to the main generator and provided power for various auxiliary machines, the battery & for exciting the main generator.

Fuel and water were carried in roof mounted tanks. Cooling of the water and oil was by the use of variable speed electric fans drawing air through two side mounted radiators. Svenska iron-nickel accumulators were located in the front and rear sections of the locomotives.

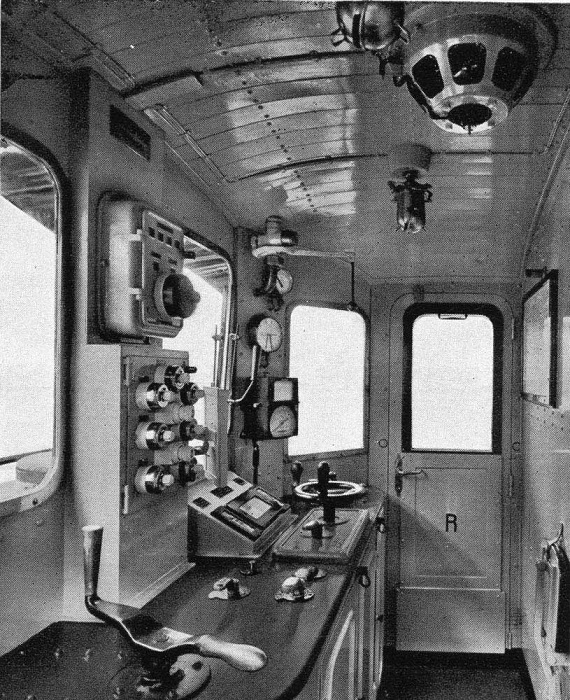

The locomotive has been so designed that it can be operated by one person. Instruments in the cab include a speedometer, a tachometer, a watt-meter displaying the main generator output and an ammeter for the traction motors. An instrument showing the state of the governor allowed the driver to detect any problems with the cylinders and also contained a device to monitor the flow of the cooling oil & water. Maximum speed was 37.5 mph (60km/h), the maximum for the main lines at that time.

Braking was by vacuum or handbrake whilst compressed air sanders were fitted on the bogies.

Although the vast majority of the locomotive frame and structure was made of metal the engineroom floor was covered with teak wood.

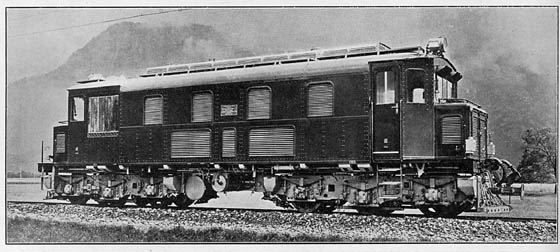

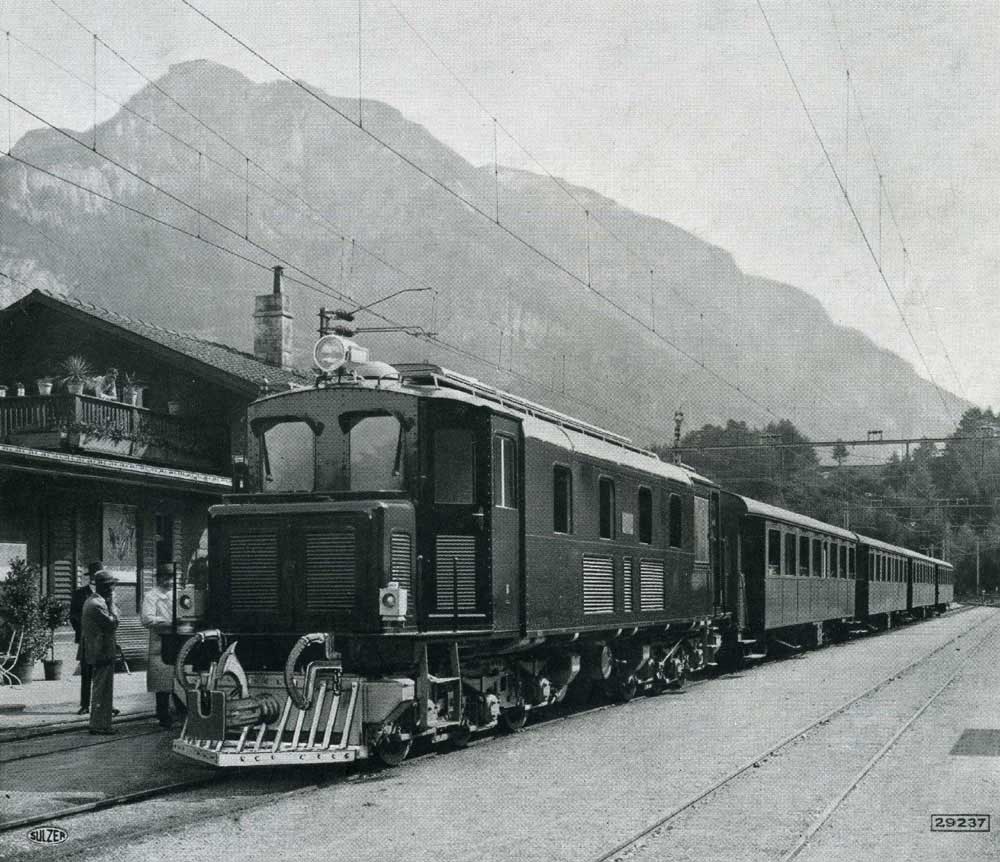

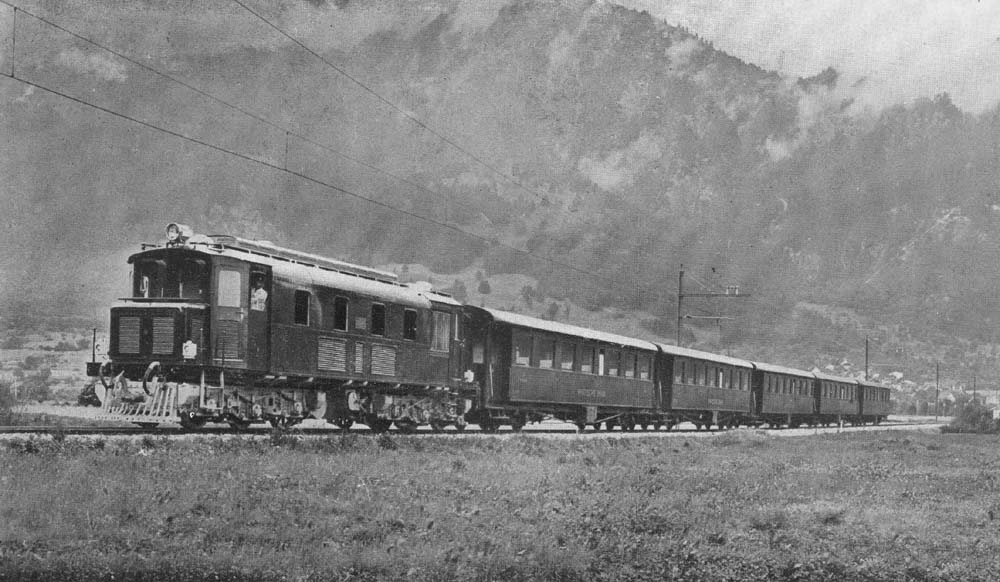

The first locomotive was tested between July 6th & 20th 1931 on the Landquart - Chur - Disentis line of the Rhaetic Railways. This route was about 73km in length with an elevation gain of just over 600 metres. Eleven round trips were made totalling 763 miles (excluding mileage through shunting). Total fuel consumption for this period, including shunting work, was 3,410lb. Starting and acceleration tests were also carried out. After stopping the train comprised of five bogie coaches (120 tons?) on a gradient of 1:37 with 100m radius curves a speed of 19mph was reached after a maximum of 35 seconds, recorded fuel consumption was 0.035lb per ton-mile. About the tests 'The Engineer' reported "from our own observation we should imagine the results must be very satisfactory alike to the purchasers and the builders of the locomotive".

The continuous output of the engine was:

at 700rpm = 450hp

at 620rpm = 400hp

at 530rpm = 340hp

The one hour rating for tractive effort at 12.8mph was 9,130lb, maximum tractive effort was 20,680lb.

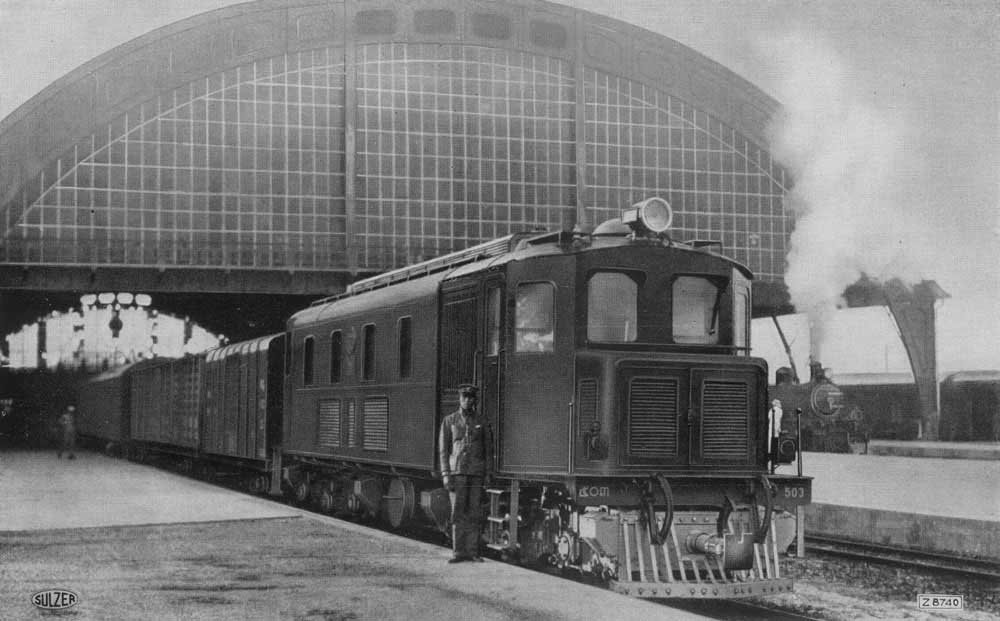

In service these locomotives worked passenger trains between Bangkok - Pitsanulok/Chiangmai (the northern line) and Bangkok - Hua Hin (the southern line). All six locomotives had each accumulated at least 700,000km prior to Siam entering World War Two. The war took its toll on the locomotives due to a reduction in maintenance and the lack of availability of spare parts. During the war one of these machines received a direct bomb hit leading to its withdrawal. Although not positively identified at the time of writing, the locomotive is thought to be 506.

After the war the remaining locomotives were returned to service as spares were shipped in during the early 1950's. As newer machines were received these early Sulzers were transferred to the Maeklong line, where 501 & 504 were still in service during 1977, one them lasted substantially longer.

(Below) Publicity views include two (top & center) taken from an advert from 1935 featuring the first order of Sulzer powered locomotives to Siam, whilst (bottom) shows No.503 in service at Bangkok.

The view below, in the public domain, shows 504 in service, judging by the condition of the paintwork it is not too long after delivery.

Unrest in Siam in 1932/1933 culminated in October 1933 with a major struggle between government forces and a group led by Prince Boworadet. By the middle of October 1933 government forces recaptured Don Mueang Airport on the outskirts of Bangkok and had driven the rebel troops back along the north-eastern railway line, causing much destruction to the airport, railways and bridges from artillery bombardment and similar.

Desperate to escape, the rebels sent an empty locomotive down the track at high speed to collide with a government troop train. The resulting crash killed a number of government soldiers and gave the rebels time to reach their base in Korat. The government moved in by rail and attacked this and other rebel stronghold in the provinces. By the end of October the unsuccesful coup-de-etat had fizzled out.

A high-ranking soldier (Major Luang Amnuay Songkhram - Thom Kesakomol) led one of the Sulzer diesels, being shot by the Price Boworadet through the front window where the driver died. The Makkasan factory hurried to work day and night to fit another Sulzer diesel with armoured cabs. LP received the Constitution Defense Medal for this improvisation.

During these troubles two Danish technicians sent by the Frichs to oversee their locomotives resigned and went back to Denmark.

At least two of these locomotives saw service into the 1990's under the ownership of the Jalan Prathan Cement Company at their Ban Sa plant near Ban Cha-am - Km 203 - on the SRT's southern line. A branch line connected with the station to their plant. The two locomotives were 504 (21828 1931) and 505 (21829 1931). 504 was noted in a shed, perhaps operational whilst 505 was plinthed near the works office.

January 2008 - 505 remains plinthed in front of the sales office of the cement works. It is located in a garden under some trees, in a somewhat photogenic location. Externally the locomotive itself is not in a too bad shape, however it is completely gutted, being used as a conference room... at this time it was advised the cement company no longer own 504 and it had been moved to a scrapyard. Information courtesy Patrick Rudin.

January 2015 - 505 remains at the cement plant as mentioned in the note above. It is expected to receive a repaint according to information recieved.

During the first quarter of 2016 505 received a repaint as shown in the views below, the locomotive has been completely gutted. Both photographs below courtesy of Paul Thompson.

504 still exists as shown in the images below, having been removed from the cement plant to a yard.

During March 2016 504 was moved to the night market north-east of Bangkok, as part of the 'Train Night Market Kaset-Nawamin'. This locomotive is also completely gutted. Both photographs courtesy Paul Thompson.

Update September 2017

More precise location details for No.504 are:

Srinakarin Train Market (Rod Fai Night Market),

51 Soi Srinagarindra 51, Khwaeng Nong Bon, Khet Prawet, Krung Thep Maha Nakhon 10250, Thailand.

(It is nearby King Rama IX Park in the urban district Khet Prawet of Bangkok.)

![]()

The Second World War

As mentioned above one of the original order of the 450hp Sulzer locomotives was destroyed by enemy action during World War II. Although not a statistic to linger over this locomotive probably has the dubious honour of being the only Sulzer powered locomotive destroyed during wartime.

However this individual loss palled in comparison with what the country suffered and the railways in general through actions taken by the Japanese, or the Allied bombing missions.

Twenty two principal station yards and signalling centers were bombed, with several being completely destroyed. Twenty five miles of track were torn up. The railway's primary workshops at Makasan, Bangkok sustained severe damage with over twenty buildings destroyed.

The general rolling stock suffered greatly. Of the 186 steam locomotives on the roster in 1939, 105 suffered damage of some sort, of these 78 would be scrapped. Two diesel electric locomotives were destroyed as were thirteen passenger coaches. Over 50% of the freight wagons were missing, either destroyed or could not be accounted for, some no doubt removed by the Japanese.

However perhaps the greatest loss was the destruction by bombing of 28 steel bridges. The loss of three of these bridges in particular caused tremendous difficulties to the resumption of traffic after hostilities had ceased.

Rama VI Bridge across the Menam Chao Phya

connects Bangkok with the southern line - this bridge consisted of five spans totalling 445 metres, rebuilt to carry the railway line, a roadway and two footways. Reopened to traffic December 12th 1953

Surat (Chulachomkloa) Bridge across the Menam Tapi

on the southern line 633 km south of Bangkok - this bridge consisted of three spans totalling 200 metres, rebuilt to carry the railway, a roadway and one footpath. Reopened to traffic February 16th 1953

Bandara (Paramindhara) Bridge across the Menam Nan

on the northern line 456 km north of Bangkok - this bridge consisted of three spans totalling 262 metres, rebuilt to carry the railway and one footpath. Reopened to traffic March 14th 1953

The original bridges had been designed for an axle loading of between 8.00 and 10.50 metric tons, the new bridges were designed with axle loadings up to 15 metric tons. In each case the foundations of the piers and abutments were reused requiring the bridges superstructure to be kept as light as possible despite the increased axle loadings. This was accomplished by the use of high tensile steel, the allowable stresses permitted were much higher than those offered by the use of heavier mild steel. The cost of rebuilding the three bridges totalled Thai Baht 54,486,722.

By January 1946 traffic was able to resume on all lines, made possible by work carried out by railway workers and with assistance from British military forces. Temporary bridges were constructed at Rajburi & Bandara. For the larger bridges at Rama VI and Surat ferries were brought into operation with quays built from pontoon and bailey bridge units. The ferries were capable of handling one locomotive or two freight cars. The temporary facilities would remain in place until new bridges were installed in 1953, as detailed above.

The lack of materials meant that repair work could not be completed as quickly as possible, fortunately rolling stock made surplus by the end of wartime activities provided the opportunity for the Thailand railways to make temporary progress in meeting traffic demands. This surplus stock included 68 steam locomotives and 675 bogie freight cars obtained from the USA, India & Malaya. This stopgap measured allowed the railway to meet increasing demand pending more permanent solutions. By 1950 long term rehabilitation projects were returning the railway to its prewar condition and by 1953 the following were ordered or in the process of being delivered:

70 2-8-2 steam locomotives from Japan

30 4-6-2 steam locomotives from Japan

18 Davenport diesels of 500hp from the USA

4 diesels of 735hp from Switzerland

3 diesels of 960hp from Switzerland

260 passenger carriages from Japan

1,000 four wheel covered goods wagons from Japan

220 low sided wagons from Belgium

10 bogie water tanks from Japan

Materials to rebuild and update Makasan Workshops

36,700 metric tons of 60lb rail from the USA & the United Kingdom

1,100 sets of turnouts (points) from the USA, United Kingdom & Japan

Steel bridge spans from Japan to replace 25 bridges.

Total estimated cost of the refurbishment was Thai Baht 537,000,000, of which 47% went to rebuilding the infrastructure - permanent way, bridges, buildings etc.

![]()

Dimensions for the Bo-Bo & A1A-A1A locomotives

| 1931 A1A-A1A | 1946 Bo-Bo | 1951 A1A-A1A | |

| Weight, empty/full | ??/60tons | 43.5/46.5tons | 54/58tons with 2,700 litres of fuel | Minimum adhesion weight | 43tons | 44.5tons | 44tons | Maximum Axle Loading | ?? | 12 tons | 12 tons | Starting Tractive Effort | 20,680lb | 20,000lb | 30,900lb | Tractive Effort - Continuous | ?? | 6,800lb @ 22.5mph | 12,800lb @ 19mph | Tractive Effort - One Hour | 9,130lb @ 12.8mph | 9,200lb @ 17.5mph | 17,600lb @ 14mph | Tractive Effort - Full Power & Max Speed | ?? | ?? | 6,600lb @ 40mph | Wheel Diameter | 36in -driving, 30in carrying | 3.00 ft | 3.00 ft | Bogie Wheelbase | 9ft 10in | 7ft 10.5in | 9ft 10in | Distance between bogie pivots | 24ft 3in | 22ft 7.375in | 25ft 7in | Length over buffer beams | 44ft 6.75in | 37ft 1in | 42ft 0in | Maximum width | ?? | 9ft 1.5in | 9ft 2in | Maximum height | ?? | 12ft 6.25in | 12ft 6.5in |

![]()

This text below is related to the affairs of the Royal State Railways of Siam, the ordering of diesel-electric locomotives, the visits to Denmark, Germany & Switzerland by Royal State Railways of Siam officials to oversee and inspect the construction of certain diesel-electric locomotives at Frich's Arhus, Denmark; Henschel Kassel, Germany and Sulzer's Winterthur, Switzerland factory. On the 2nd trip it includes some staff being stranded in Europe for seven years as the events of World War Two and its aftermath unfolded.

The story was originally posted in the Thai language circa 2005, with a couple of translation engines used to 'convert' to English. The link to the original text is at:

http://portal.rotfaithai.com/modules.php?name=Forums&file=viewtopic&t=627&start=0

Some of the translations are a little rough and where known additions have been made to help the story flow more easily.

The storyteller is Luang Prasitkamai (LP) (title: Prasit Menasawet), the first electrical engineer in Thailand to graduate from Cornell University, USA, having received a scholarship from the Ministry of Public Works to study electrical, telegraph, telephone, and signal mandate engineering in the United States. LP graduated with a Professional Degree in Electrical Engineering, a degree higher than a bachelor's degree.

Upon returning from the USA to Thailand in 1924, LP joined the government service at the Department of Royal Railways in the position of assistant electrician and received the rank of Deputy Chief of Staff before moving to work at the Samsen Metropolitan Electricity Authority and the Bangkok Electricity Authority, respectively, in 1931. Later when the Royal Railway Department ordered diesel-electric locomotives (from Frichs & Sulzer) LP returned to the Mechanics Department.

LP was sent to Europe (Frichs, Denmark?) to study the construction of diesel-electric locomotives. This would allow him to train employees in their use and maintenance.

The electrical equipment for the Frichs & Sulzer locomotives was supplied by Oerlikon of Switzerland. The three of us, Mr. Sui Sirisuk (Luang Witoon), Mr. Chang Khon, Mr. Prasit Menasevet, Mr. Electrician and Mr. Robert Sanguanchart, Locomotive Inspector travelled to Frichs factory in Aarhus, Denmark. It was noted that the Frichs factory is only slightly larger than the Makkasan workshops of the Royal Siam Railways.

Whilst in Denmark the party were informed that the British consulting firm CP Sandberg, who were used to supervise inspections on the locomotives had sent their staff to Switzerland. Thus LP and the mechanic left for the Sulzer company, while Robert remained at Frichs.

On this trip, LP visited Henschel in the city of Kassel in Germany, who made the mechanical locomotive parts for Sulzer. We also witnessed the testing of the completed locomotives, on the Chur to Disentris line. Also present from Thailand were Phraya Sarasart, Railway Commander and Khun Phra Suwaphan, Director of the Locomotive, both visited Frichs & Sulzer. On return to Bangkok we travelled via Paris, then London, staying there for a week before boarding a ship home.

Unrest in Siam in 1932/1933 culminated in October 1933 with a major struggle between government forces and a group led by Prince Boworadet. By late October 1933 government forces had quelled the rebellion, which led to the removal of the telegraph, telephone and signals engineer, who was thought to be involved with the rebels. He was replaced by LP.

LP investigated problems with the large Frichs locomotives whilst they were working the express train south of Bangkok to Penang. Reported defects were causing the train to lose time. The cause was not immediately clear so LP rode in the cab to observe the gauges. The observations indicated the diesel engine was overloaded, which came as a surprise to LP. On consulting the documents provided by Oerlikon, it was discovered the problem related to the amount of acceleration supplied by the locomotive. It is presumed that further driver training led to the locomotives being operated within the manufacturers specification, causing the problem to disappear.

In another story about one of the Frichs locomotives which was about a year old, a recently repaired locomotive about to be returned to traffic would not move. LP checked the locomotive and confirmed the main generator had gone to ground. On closer investigation the insulation on one of the cables had failed due to vibration, causing a short circuit through the frame of the locomotive. Repairs soon made the locomotive serviceable.

Due to the shortage of spare parts for the Frichs locomotives, which were used on the international express train, it was suggested that the train revert to steam haulage which would require the retiming of these trains. LP suggested using two of the Sulzer locomotives as a substitute. To ensure this would work a test run was arranged. LP was accompanied by two senior officials from Padang Besar. From Taling Chan to Nakhon Pathom the performance of the two locomotives was not good, possibly the two diesels were not working properly in multiple, this was soon rectified. Later that night the train was stopped for a long time at Map Amarit station. For some reason a locomotive was having battery problems and was not able to start the engine. Eventually a cable was found to make the necessary connections, the train restarted and made its way to its destination at Padang Besar. On the return trip an extra coach was added, it was thought the train might need assistance from a steam locomotive, but it was found not necessary even in the mountain district at Thung Song.

With the success of the diesel fleet a further supply of diesel locomotives was sought. Two proposals were received; from A.E.G., Germany and Sulzer, Switzerland. The order was given to Sulzer and three officials travelled to Europe to make inspections. Previously the Sandberg Company had been used to make the inspections, but this had been a considerable expense previously and the action was not repeated. The persons sent this time were the Schemes Mechanic Division Leader, the Chief of Electric Division (LP) and the Locomotive Inspector. We left Bangkok, sailing from Singapore to Naples, the journey taking place at about the time that Germany invaded Denmark (April 1940). From Naples the journey continued by train to Zurich. The city was very subdued, fearing an invasion by German forces into Switzerland. The Sulzer representatives warned of this possibility, advising to take an 'escape' route through Geneva, but no invasion occurred.

For Sulzer and Oerlikon their activities continued as normal.

At this time the Chief of Mechanic Planning Division (...not named because it's a royal family member...) fell ill with a severe nervous breakdown. Permission from the Department to return according to the opinion of the doctor was received, travelling back with the delegation of Chao Khun Vichit via Russia, which was the only way in 1941.

Meanwhile, Sulzer's master craftsman, his assistant and LP, travelled to Kassel, Germany to inspect the locomotive(s) at the Henschel factory. By this time Germany had declared war on Russia. A member of the Henschel staff distributed coupons for food purchases. Meals were very limited and basic e.g. dinner will only include mashed potatoes and gravy and no coffee. At night there was a blackout.

After whatever business needed to be completed in Kassel, we hurriedly returned to Switzerland, uncertain of the very fluid situation in Germany.

After delivery of the first locomotive to Sulzer, they proceeded to finish assembly and then had the locomotive weighed in the government(?) machine shop. This was to ensure the axle loading specification had been met. LP looked at the results and felt something was wrong, so refused to sign the acceptance. A meeting at the Diethelm Company followed. Sulzer argued that its because they use a spring type machine rather than the tateng type. It was agreed to go and do the weighing again by using the tateng. A member of the staff from the director's office at Diethelm accompanied us for the re-weighing, which produced a satisfactory result. (The Diethelm Company specialised in the trading of products between Europe & Asia and maintained an office in Zurich.)

Then followed the road testing of the locomotive, to which His Majesty King Ananda Mahidol and His and Her Royal Highness Princess Maha Chakri Sirindhorn had been invited. Both of them had left Lausanne on July 2nd 1941 and spent one night in Z rich. In this regard, Luang Atthakitikamjorn was in charge of treatment. Mr. Sulzer, the president of the company, welcomed the group On July 3rd 1941 and a tour of the Sulzer factory followed. The group then travelled to Chur to witness the test of the locomotive. (King Ananda Mahidol: born 1925, died 1946; reigned 1935 - 1946 mostly whilst living in Switzerland, was murdered shortly after his return to Thailand in 1946.)

His Majesty the King and His Royal Highness travelled on the locomotive with the driver whilst Her Royal Highness Princess Maha Chakri Sirindhorn sat in one of the coaches. On this test run His Majesty the King and His Royal Highness took the controls of the locomotive guided by the driver and a master craftsman (designer?) from Sulzer. He (the King?) was very pleased and drove all the way from Chur to St. Maurice, a distance of about 320km, a mountain road on both sides with very beautiful scenery. (Generally metre gauge Sulzer locomotives were tested on the metre gauge Rhaetian Railway based at Chur.)

A luncheon followed at the Hotel St. Maurice for all the guests from Siam and a complement of Sulzer staff. The party return to Chur by train. HRH Princess Maha Chakri Sirindhorn gave dinner to LP and Luang At in Zurich before returning to Lausanne.

Shortly after the road test of the first locomotive, the Master Engineer Sulzer came and said to LP that the ongoing war will prevent shipment of the locomotive, with no end in sight for the conflict. Leaving the locomotive idle for a long time may cause damage to various electrical machines. It is necessary to move it from time to time. In addition, it must be deposited and stored elsewhere. There must be expenses related to laying tracks, storage fees, etc. LP advised they can't afford to pay anything, in the contract it says Sulzer must deliver the locomotive to its place in good order. It was later ascertained that Sulzer (?) deposited the locomotive with the company where the road tests took place. LP went to meet with the general manager of that company, who confirmed the company does not charge any storage fees. It was an exchange of mutual benefits. During the war the Swiss government manned the availability of steam locomotives ready to operate immediately in the event of an emergency. In normal times the company uses an electric train, now with this new diesel locomotive as a backup the company didn't have to pay for use of the steam engine. (Presumably the locomotive was stored at the Rhaetian Railway facilities at Chur.)

A friend of LP works for Brown Boveri Company, a large electrical company. The friend advised that the company would like to invite HRH Princess Maha Chakri Sirindhorn & His Majesty the King to view the factory I therefore asked to meet with HRH Princess Maha Chakri Sirindhorn. His Majesty ordered that "Luang Prasit, I help" because during that time Sulzer were acting rather taut(?).

HRH Princess Maha Chakri Sirindhorn with her two sons and accompanied by Mr. Phra Phaita, the Siamese ambassador visited the factory. They were shown lighting (artificial lighting) using high voltage and operating gas turbines. This company built one gas turbine locomotive which is currently being tested, if successful it may be better than diesel electric locomotives.

About the locomotive testing and storage LP hastened to telegram the Department so they would know the latest position. By the royal patronage of HRH Princess Maha Chakri Sirindhorn we received great help from the ambassador, who managed to send my telegram using the code through the Ministry of Foreign Affairs to the Department of Railways, Siam.

At that time, LP was in great need of money. Before the end of World War II LP went to Sulzer to meet a craftsman who had just returned from Kassel. We greeted each other as friends and asked if LP had heard that Kassel was bombed by the Allies. How was Henschel? He laughed and replied that it was true, Kassel was bombed but the Henschel factory was fine, as if it was American intention.

After World War II ended a letter was received from Sulzer stating that our locomotive order was voided because the Henschel plant had been bombed. They couldn't send the remaining five locomotives later, when talking to friends who are well-informed, it says due to heavy damage in Europe. There have been orders from factories in Switzerland, so many that it is expected that during the 3-year period, they will not be able to accept anything else. Sulzer would probably sell our locomotives for a price that could almost double. Padasawat Balangkun, a law student bringing the matter to discuss with his professor, he was of the opinion that if the government sues us, we will definitely get the locomotive because we have been there to inspect and test every piece of the machine. In addition to the carbody at Henschel, there has been a case like this before the Swiss courts. The case decided for the purchaser, LP therefore made a detailed report letter and deposited with the Royal Secretary (the evidence is kept at the National Archives).

When His Majesty King Ananda Mahidol returned to Bangkok by a plane provided by the United States on December 5th 1945, those of us caught in the aftermath of the war still had to wait. Until he heard the news of the death of His Majesty King Ananda Mahidol having paid homage to each other at the Palace of Lausanne Until His Majesty King Bhumibol Adulyadej came back to study in Lausanne. So LP had the opportunity to travel home by ship of the Isasiatic?? company from Malsel (Marseilles?), France, travelling first class and then charging the government later in 1946.

When he returned to the story, there was no mention of the locomotive(s). No one asked about the royal secretary who took me to meet Luang Thamrong, Prime Minister at that time at his house told the whole story, but remained silent as before until one day while working in Makkasan factory LP received a call from the Permanent Secretary that the minister wanted to meet with Luang Dechatiwong as the minister. He said he would ask the United States to check whether the Henschel factory was really damaged by bombing? Shortly thereafter, the minister died on February 1st 1947, with the convoy he traveled along the Death Railway crashing into the abyss at Kaeng Khoi Tha. The matter was quiet again. (On February 1st 1947, two people including Momluang Kri Dechatiwong, the Minister of Transport, were killed on an inspection tour 500 metres before Konkoita station. Their trolley was supposed to pass over the bridge after a curve, however it had burned down and collapsed causing the trolley to drop 8.5 metres.)

Until when LP was about to move to the Electricity Authority of Bangkok, Mr. Chang Khon Ek (Ch.A.K.A.) came and said that we would get the ordered locomotives back. He negotiated with those above (overhead?). It was about 3 years later, LP was very happy because he knew that many government orders placed in Europe were to be completely void. For example, Naresuan and Taksin cruisers ordered by the Royal Thai Navy from Italy. Many high-ranking naval officers went to control, it was void, had to negotiate to pay the pounds back.

Going to work this time was not as smooth as last time because of the lack of money. If not receiving the royal grace from Her Royal Highness Princess Maha Chakri Sirindhorn LP didn't know how to proceed. All correspondence with the post office was cut off when Germany declared war on Russia for about seven years. But almost not. Khun Jaroon Suebsaeng said that when the salary increase was considered that time the supervisor did not consider it. It can be seen that it's because they already have both salary and allowances. But he is the one who thinks that it should be considered. As for the collaborators, they hear the tragic news that Master Engineer Henschel's wife was captured. The Nazis accused him of having Jewish blood and died in prison with the Jews.

Sulzer, on the other hand, had to sympathize with his financial struggles. Because he didn't get it from us at all. But he had to pay his employees. as well as to Oerlikon and Henschel.

Later, Sulzer contacted the factory in Belgium (SA La Metallurgique Nivelles?) to assemble the locomotives (carriages?) instead of Henschel. Because the Henschel plant had been attached to the mission of assembling locomotives for the US Army that set up a military government in West Germany.

LP was appointed as the Acting Officer in the position of Chief Mechanical Engineer because the CHAC travelled abroad with the faculty to procure various materials for the Department of Railways. CHAC requested to review the vehicle purchase contract. Diesel locomotive for use with the Southern Expressway and send it as soon as possible. The important thing to add is there is a plan showing the way up and down the curves etc. of the Southern Railway. This is to try to get the builder to find the right power size of the locomotive. The construction uses BSS (British Standard Specification) and for transparency there is a message that the buyer has the right to cancel the contract immediately if it appears that bribes to officials whether directly or indirectly.

In addition, the activities that have been done are the change of vans to Class 3 buses due to the shortage of buses. Consider purchasing machine tools for the Makkasan factory. Explore the stranded post-war Malay train wagons to return. On this occasion, information on the cost of using a steam locomotive versus a diesel locomotive was obtained to see how different investments are. It turns out that although the price of a diesel locomotive is higher than a steam locomotive, but when used for about three years, all expenses including the price of the locomotive will be the same, so using a diesel-electric locomotive instead of a steam locomotive thus saving without problems.

The diesel-electric locomotive that the group travelled to contact had five tenders, three from American companies, one from England and from Sulzer. The official has ordered me to be the sole reviewer of the auction.

Checking the list must be done at the Office of the Permanent Secretary. Documents cannot be removed. American General Electric Company and English Electric Company of England have sent representatives to contact to clarify details and observe. In consideration, Sulzer was ruled out because the price was so high. The rest, including General Motors, English Electric, General Electric and Davenport, have made a price comparison, weight, towing capacity, respectively, submitted as a confidential report.

Authorities have settled in favor of Davenport, which offered the lowest price. Everything was proceeding smoothly. There was no objection from the bidder and the panel in the bidding review report.

LP have proposed a comparison of the use of a steam engine and a diesel engine. Which LP have examined as written above because as far as it is, it is only known that diesel locomotives saves fuel. But there is still no figure on how much savings can be made. Fuel costs are the heart of the railway's profit and loss. It's the biggest expense compared to salaries and general maintenance added to it. As an idea for ordering more locomotives in the future. Knowing that at that time The Korat line goods train using the steam locomotive must cut the train at Ban Phachi, because there is always theft (lost time?).

LP have commented that if instead of using a 900 sqm diesel-electric locomotive, it will be able to operate without having to cut the train. However, it must be seen that asking to tow can endure it or not. The matter of "Kha" has received a lot of attention from the mechanics department, have checked and seems to have changed to be stronger until it works well.

My official service in the Department of Royal Railways has come to an end. Upon receiving an order from the ministry to work as Deputy General Manager of Bangkok Electricity Authority as requested by the Ministry of Interior. To receive a replacement pension at the Office of the Permanent Secretary, Ministry of Transport, the Department of Railways has granted a lifetime pass as a pension, to be able to travel all the way, all routes without limitation on first class and two followers traveling the third class.

Addendums to the above document by another writer

(Sources not stated but thought to be from government and railway records.)

The first 2 SLM 735hp locomotives are still a bit better than the year 1946, but the last 2 SLM 735hp locomotives until the year 1950 and all 3 SLM 960hp locomotives are probably getting in 1951 because the Belgian factory at Sulzer had to be assembled for the locomotive, because Henschel was obliged to produce locomotives for the American army and had to pay more ... by:

1. Half payment in cash ... if paying in US$ (if gold Swiss Francs cannot be found), the surcharge must be charged 7.25-7.5%.

2. The rest must open L/C (Letters of Credit) and Union Bank of Swiss, New York City branch.

Here, if the King doesn't ask for it, he probably won't get five more SLM locomotives because SLM will find a way to cancel the contract by referring to Section 83.

Continuing to order a Swiss diesel locomotive 7 after the Document Office of the Prime Minister (2) Sor Ror. 0201.16.2/3 send a Thai technician to supervise the construction and inspect the goods and appliances of the Department of Railways ordered from abroad.

Wednesday, October 18th, 1939 in the Cabinet meeting The Department of Railways intends to save on expenses spent on consulting firms. (CP Sandberg Company - CP Sandberg) is in charge of construction and inspecting items of the Department of Railways, which charges a commission of 3 percent of the purchase price. Therefore, the Cabinet has requested a resolution to send 3 Thai technicians as inspectors of the construction and inspecting items of the Department of Railways ordered from abroad. By taking the money that will be paid from the 3 percent commission that is normally paid CP Sandburg Company came to pay, which the Cabinet approved as proposed by the Department of Railways. But must have an official confirmation letter first.

November 7th 1939 Colonel Phra Boriphan Yutthakit Minister of Economic Affairs (Ministry of Economic Affairs) presented a policy memo to the Department of Railways. Sent 3 Thai technicians to supervise the construction and inspection of appliances purchased from foreign countries in Europe, dated October 31st, 1939, for the Prime Minister to be informed. Explained that if the consulting company still (CP Sandberg Company - CP Sandberg) is responsible for supervising the creation and inspection of items purchased from abroad. There must be expenses as follows:

1. Inspection Fee - Retainign Fee 250 pounds per year (1 pound equals 11 baht).

2. Fees calculated by percentage, CIF price according to the following items.

2.1 Items purchased from England and the United States where CP Sandberg has branches

- Steel rails and accessories 1%

- 3.5% spanner head and wayout

- Locomotives and wheels 2.5%

- Bridge machine 3%

- Other items 3.5%

2.2 Items purchased from European countries where CP Sandberg does not have a branch.

- Steel rails and accessories 1%

- Wrench head and way 4%

- Locomotive and 3% wheels => The problem is here.

- Bridge Machine 3.5%

- Other items 4%

Now the Department of Railways has agreed to order. The following trailers and locomotives:

1. 3 electric trams + 6 trailers for the Pak Nam Railway

2. 7 electric diesel vehicles for main roads

In addition, tenders for the purchase of the following locomotives and trailers have been called. after receiving a 2 million baht loan from the Ministry of Finance which the Department of Railways will repay with the renovation fund of the Department of Railways in 3 years, namely (according to documents Office of the Prime Minister (2) Sor Ror.

1. Pacific Locomotive The price is about 70,000 baht per car, a total of 10 cars, a total of 700,000 baht (later the Pacific Locomotive Model 282-291).

2. All steel buses, about 40,000 baht each, 20 cars, totaling 800,000 baht.

3. Cargo trucks, about 2,500 baht each, 200 units, totaling 500,000 baht.

However, in the project there is a correction.

1. Buy 31 fully assembled steel buses.

2. Buy a passenger bogie frame and the technicians of the Department of Railways will use teak wood or high grade wood to assemble 9 cars.

3. Purchase 800 different types of cargo trucks.

Part of expenses paid CP Sandberg Company - CP Sandberg (excluding the 250 per year commission already paid by the Department of Railways) has the following statistics:

1. Inspection Fee - Retainign Fee 250 pounds per year (1 pound equals 11 baht)

2. Fees calculated by percentage, CIF price according to the following items.

2.1 Items purchased from England and the United States where CP Sandberg has branches

- Steel rails and accessories 1%

- 3.5% spanner head and wayout

- Locomotives and wheels 2.5%

- Bridge machine 3%

- Other items 3.5%

2.2 Items purchased from European countries where CP Sandberg does not have a branch.

- Steel rails and accessories 1%

- Wrench head and way 4%

- Locomotive and 3% wheels => The problem is here.

- Bridge Machine 3.5%

- Other items 4%

Now the Department of Railways has agreed to order. The following trailers and locomotives:

1. 3 electric trams + 6 trailers for the Pak Nam Railway

2. 7 electric diesel vehicles for main roads -

In addition, tenders for the purchase of the following locomotives and trailers have been called. after receiving a 2 million baht loan from the Ministry of Finance which the Department of Railways will repay with the renovation fund of the Department of Railways in 3 years, namely (according to documents Office of the Prime Minister (2) Sor Ror.

1. Pacific Locomotive The price is about 70,000 baht per car, a total of 10 cars, a total of 700,000 baht (later the Pacific Locomotive Model 282-291).

2. All steel buses, about 40,000 baht each, 20 cars, totaling 800,000 baht.

3. Cargo trucks, about 2,500 baht each, 200 units, totaling 500,000 baht.

However, in the project there is a correction.

1. Buy 31 fully assembled steel buses.

2. Buy a passenger bogie frame and the technicians of the Department of Railways will use teak wood or high grade wood to assemble 9 cars.

3. Purchase 800 different types of cargo trucks.

Part of expenses paid CP Sandberg Company - CP Sandberg (excluding the 250 per year commission already paid by the Department of Railways) has the following statistics:

In 1936, the figure was 941 pounds, 11 shillings, and 4 pence.

In 1937, the figure was 1077 pounds, 5 shillings, and 1 pence.

In 1938, the figure was 5504 pounds, 8 shillings, and 9 pence.

Year 1939, the account has not yet been closed.

When this Therefore, a Thai technician should be appointed and stationed in England to inspect the objects of the Department of Railways and all ministries, sub-ministries and departments have ordered. It will be beneficial to the government, that is, it will save the commission that must be paid to foreign consulting firms.

November 9th 1939, Mr. Direk Chainam, Secretary-General to the Minister Report of the Minister of Economics that the cabinet approved the sending of 3 Thai technicians to supervise the construction and inspection of the Department of Railways equipment ordered from abroad, as proposed by the Ministry of Economic Affairs.

March 11th 1939, the result of the purchase order 7 diesel-electric locomotives as a result Sulzer Company at Diethelm Become a representative in Bangkok Winning the auction according to the price as follows:

- Diesel-electric locomotive, 735 horsepower, 4 cars, each car 295,880 Swiss Franks, total 1,183,520 Swiss Franks

- 3 diesel-electric locomotives with 960 horsepower, 378,050 Swiss Franks each, total 1,134,150 Swiss Franks

Therefore, it is expedient to send 3 Thai technicians to supervise the construction and inspection of the Department of Railways equipment ordered from abroad. instead of Sandberg Company, including:

1. Mom Chao Sitthiyakorn Worawan, Chief of the Mechanic Division, is the chief.

2. Luang Prasitkamai Chief of Electric Division

3. Mr. Sawang Kanchanalai, factory inspector

Scheduled to travel in April 1940 and will stay in control until the locomotive is completed for 18 months, returning due to Europe being at war. The establishment of an office cannot be chosen as a suitable center. And the technicians that were sent out probably did not work with their hands full because there is no office therefore waiting for the appointment of a regular technician first. But keep the appointment of 3 officials from the Department of Railways to go abroad.

March 13th 1939 in the cabinet meeting, the meeting resolved to Ministry of Economic Affairs Proceed to send 3 technicians to supervise the construction of the locomotive. As for the money, continue to agree with the Ministry of Finance.

March 16th 1939 Secretary of the Cabinet Inform about the Cabinet's approval for railway officials to travel abroad.

September 9th 1941 Minister of Transport by the Permanent Secretary [Luang Khakhabordi] signed on behalf of the Minister of Transport. [Luang Seree Ruengrit] was attached to the field service, informed that Prince Sitthiyakorn Worawan, the head of the mechanic division who went to supervise the construction of a locomotive in Switzerland He fell ill in early June 1941. The doctor in Switzerland advised him to return to Thailand urgently. Mom Chao Sitthiyakorn Worawan asked for permission to travel back on June 20th 1941, traveling with Lieutenant General Phraya Wichit Wongwutkrai. (Mr. Sitthi Suthat - Samura Ongkharak) through the Soviet Union, Russia (Trans-Siberia Railway), which has been approved by the Ministry of Transport. Because he saw that most of the control work had already been done. Enough for other controllers to be able to continue the work, and Prince Sitthiyakorn Worawan has incomplete politeness. Therefore approved as requested and Mom Chao Sitthiyakorn Worawan arrived in Thailand on August 6th 1941.

December 17th 1942, the Ministry of Transport notified the Ministry of Finance. Paying allowances to Mr. Prasit Menesawet (in the era of catastrophe, spelled as Mr. Prasit Menasevet - Luang Prasitkamai) and Mr. Sawang Kanchanalai, even though it has been more than 18 months since the war has covered the whole world. which the Ministry of Finance approves but must be approved by the cabinet first and the Ministry of Finance has informed the Secretary-General of the Minister.

Charg d'affaires of Thailand to Switzerland reported by telegram to the Ministry of Foreign Affairs that Mr. Prasit Menasevet and Mr. Sawang Kanchanalai were still serving in Zurich, Switzerland (Location of Diethelm Company Switzerland branch).

On December 21st 1942, the Secretary-General of the Minister (Mr. Tawee Bunyaket) informed the Ministry of Foreign Affairs to clarify the reasons for the Cabinet to continue paying allowances until both Thai technicians returned to Thailand. Later, on January 5th 1943, Mr. Wichit Wichitwathakan (Luang Wichitwathakan) informed the Minister's Secretary (Mr. Tawee Bunyaketu) that the two Thai government officials were in Zurich. Switzerland and the war situation made it impossible to return.

January 14th 1943 Secretary-General (Mr. Tawee Bunyaketu) informed the Minister of Finance that The Cabinet had a resolution on January 13th 1943 to continue paying until returning to Thailand.

In January 1946, Sulzer Company notified Diethelm Company which has an office in Zurich that the company wants to terminate the contract with the Department of Railways in building five locomotives (two 735 horsepower and three 960 horsepower) alleging that the Henschel plant, which was a sub-contractor for vehicular parts production and assembling locomotives, was damaged during the war and report this through the Thai Embassy in Bern.

Later, Luang Prasitkamai inquired a Swiss engineer who went to Germany to know that the vehicular part at the Henschel plant still good, no damage but can't take it out because the Henschel plant under the control of the United States military government. Causing to send a telegram from the Thai Embassy in Bern to the Department of Railways what to do next. Then the Department of Railways presented the matter to the Ministry of Transport. Then the Ministry of Transport has presented the matter to the Ministry of Foreign Affairs.

Ministry of Foreign Affairs sent the matter to the Thai Embassy in Washington DC to contact the US State Department. Proceed to notify the US military government in Germany to allow the vehicular part stored in the Henschel plant. Hand over to Sulzer, through the US Ambassador Bourne.

October 1946 Sulzer Company delivered two 735 horsepower locomotives (Locomotive No. 651-652) to the Department of Railways through the port city of Genoa.

At the same time The Cabinet resolved to negotiate a compromise to maintain the contract for assembling five more locomotives because at that time locomotives were scarce. The Department of Railways urgently needs a locomotive for official use and want to maintain a relationship with the company because the locomotive parts were ordered to repair existing locomotives and new locomotives as well.

The company informed that the price of five locomotives before the war was estimated at 1.6 million Swiss Francs. But after the war, the figure was 2.4 million Swiss Francs. And allow the Department of Railways to pay 50% in cash and open a letter of credit (currently regulated as credit instruments) with the Credit de Suisse bank, but the Department of Railways does not have Swiss francs. therefore wishing to pay in US dollars The company will charge 7.5% interest.

Later negotiate until the end. The company asked the Department of Railways to pay 2.2 million Swiss francs. In US dollars, 1,261,000 Swiss francs were paid in cash. In US dollars is the engine and electric machines of Sulzer. The remainder is to be paid by opening a letter of credit with Credit de Suisse, New York branch.

During the letter of credit payment, it was found that sometimes there was not enough money in the letter of credit account. Causing the Thai Embassy in Washington, DC and the Royal Thai Embassy in London to issue money to close the shipping budget for spare parts and locomotives then go and collect it with the train.

Debt settlement that Luang Prasit Kamai borrowed 9,000 Swiss francs from the Thai Embassy in Bern and a telegram fee of six hundred Swiss francs. That Luang Prasit Kamai used to contact government officials with Thailand and personal money of HRH Princess Maha Chakri Sirindhorn which was bestowed upon Luang Prasit Kamai to lend 4,000 Swiss francs to the Ministry of Finance. The bank ordered the payment by telegram to the Thai Embassy in Bern on February 12th 1952 and the embassy confirmed it to the Ministry of Foreign Affairs on May 15th 1952.

Sources:

Railway Gazette, August 7th 1931, Diesel Railway Traction April 1946 & February 1951.

Sulzer Technical Review, Special Number 1933

Railway Gazette, Overseas Edition 1951

Railway Gazette, Overseas edition, 1954

The Railways of Thailand - Roel Ramaer, White Lotus, Bangkok 1994.

Page added April 21st 2003.

Page updated March 8th 2025.

Page for the 1945/46 & 1951 locomotives

Return to site menu