Moss Bay

The line between Moss Bay Iron Works and Parton was singled from March 1970 owing to the unstable cliffs along this section of line.

For the journey north from Whitehaven the railway line hugged the coast providing some spectacular scenery before approaching Workington. Here the evidence of industrialisation manifested itself very quickly. As the railway curved slightly passing Salterbeck the British Steel Corporation's plant would come into view as the line approached Moss Bay.

However one might feel about the location of this large industrial complex it brought jobs to the Workington area, much traffic to the railways and produced products that could only be used by the railways. The mid 1870's saw the development of the Moss Bay site into an industrial complex with blast furnaces producing pig iron and then steel. During 1877 the first steel rails were produced from the recently completed rolling mill. From 1881 the company was known as The Moss Bay Hematite Iron & Steel Company Ltd. Names changed to the Workington Iron & Steel Company, United Steel Companies, and then after nationalisation in 1967 the plain and simple British Steel. A merger in 1999 brought a new company, Corus into the picture, who kept the railmaking plant open until 2006.

Steelmaking had ceased in 1974, ingots (blooms) were then received from Teeside, Moss Bay's electric arc furnaces were used to reheat the ingots prior to rolling out into rails. That the rail from Workington was of high quality and well known throughout the world seemed to have little influence on events that would see Workington lose ground in its share of rail products. Workington had been supplying welded rail in lenths upto 180 metres, welded from shorter 32 metre lengths. Rail operators preferred the factory welded lengths rather than welding lengths together on site since the latter had a perception of being more likely to give problems. However rail operators, including Railtrack were increasingly looking for longer rail lengths that contained fewer welds of any kind. Many of the West European manufacturers made the required investment to meet this new demand from the operators.

British Steel took a different track by improving the welding facilities at Workington and making no change as to the basic length of rail that would be produced. As other operators sought the longer welded rail, events such as the Hatfield derailment and the general desire for Railtrack also to purchase the longer lengths led Corus in 1999 to acquire for GBP83 million the French rail making plant at Hayange. Studies had shown that a GBP50 million investment at Workington would have allowed the plant to make the longer rails. That Corus could ship long welded rail lengths from Hayange, France through Teesport to the local destination in the UK at cheaper cost than a similar product made at an upgraded Workington plant has to make one wonder, and realise that the writing was on the wall for the Workington plant.

Workington was still producing short rail lengths, as was Hayange, but Workington no longer had the long rail making capacity, thus increasing the fixed overheads and making the plant less competetive. And so in 2006 rail making would move from Workington to Scunthorpe.

Derwent Ironworks

Beyond the Moss Bay facilities was the Derwent Ironworks which also generated much freight traffic.

The 1975 view above of the distant Class 25 was one of Ian's pictures taken early in his photographic career. The view is taken from Derwent Haematite ironworks looking north, the Class 25 was working the 8E76 service, a shortlived working from Workington to Sheffield Tinsley to provide a through service for ingot-moulds traffic for British Steel. The coal mine to the right was the penultimate deep coal mine in West Cumbria and had closed in April 1973. The train is on the Up main line heading south having just left Workington Down yard. To the left are the slow, or goods lines which ran north to south from Workington No3 to Moss Bay Ironworks, and with another three boxes inbetween; No2, No1, and Derwent Haematite ironworks, which was behind the photographer to the right.

Workington Down Yard

Ian describes the shot above as a lucky one, featuring 47077 North Star & 850 Lord Nelson, showing a W.R. & ex S.R. machine at one of the farthest flung outposts of the L.M.Region! The clean Class 47, maybe not too long out of the Works, had failed and was about to be hauled dead-in-transit to Carlisle Kingmoor. 850 had worked an excursion to Sellafield and was en-route to Carlisle Upperby, prior to working south ex-Carlisle the following day over the Settle & Carlisle. The picture was taken looking south from No.2 signal box in 1980. The bridge in the background at the time was un-named, but would be replaced about five years later by an ugly concrete structure, given the grandiose title 'Bessemer Way Bridge', which over the years has caused some confusion!. The original bridge in the shot carried a standard gauge line connecting the nearby Solway Colliery with the ironworks site, which in turn probably replaced an earlier colliery tramway. The Class 08's lurking in the background are probably 415 & 419.

During 1975 there were four trains working in from Redcar or Lackenby generally hauled by pairs of Thornaby or Immingham Class 31's with the Lackenby working also featuring pairs of Class 37's:

6M33 07.30 from Redcar, return 6E37 at 13.59

6M71 03.10 from Lackenby, return 4E36 at 09.35

6M52 01.30 from Redcar, return 6E48 at 07.55

6M59 13.35 from Redcar, return 6E49 at 19.52

Workington

Workington at one time had its own depot, being a sub-shed to Barrow and allocated depot code 11B. It later became a sub-shed to Carlisle and allocated the depot code 12D. With the implementation of the computerised TOPS system the depot acquired the code WK, although by this time its only true residents were the Class 08 shunters that worked the yards in and around Workington.

Workington station would later become the stabling point for diesel locomotives, with its typical mix of LMR allocated locomotives. The most familiar locomotives parked around the station would be of Classes 08, 25, 40 & 47.

The timetable changes commencing May 1977 saw the loss of the through services from Euston (the 07.45 Barrow - Euston & 18.05 return) utilising the later model MkII coaches and a Class 47/4. New services from Barrow to Lancaster/Preston would now provide the connections to/from London as well as a Barrow - Crewe service. The only remaining through working was the sleeper service and the postal/parcels turn to Workington which was seeing a greater use of Class 47/4's in replacement of the Class 40's. The coaching stock of the postal trains show up in a number of Ian's Workington views.

The Classes 45 & 46 - Strangers in Town

At the height of the national lorry drivers strike at the back end of the 1970's Ian was night shift yard foreman at Workington. On this particular night it was a Sunday, with a midnight start but only a six hour shift! On arrival the yards were filled with outward bound wagons loaded with pig iron, ex-British Steel. Because of this the instruction was given to load the 03.00am Workington - Carlisle to capacity, with 1,220 tons trailing this Class 8 freight.

For this working a Class 37 was rare, Class 40 was normal and a Class 47 occasional, with provision also made for a Class 50! All these locomotives were allowed the same loading, but the Class 45/46 were allowed an extra 200 tons. During the course of the shift Ian had reason to speak to Carlisle Control and requested a Peak for the rest of the week, but without much hope.

Remarkably Carlisle sent down 45044 with the train being loaded up with an extra 200 tons. And as regular as clockwork 45044 showed up again on Tuesday, Wednesday & Thursday. Somewhat bemused by this good fortune Ian inquired as to how the same Peak had showed up four days in a row? The response was the locomotive was on a restricted (local) working because the traction motors were isolated on one bogie! Which has to be some sort of testament to these fine workhorses.

Workington Open Day

During 1982 Ian had visited an Open Day event at Carlisle and went home thinking, well if they can do this, then we can put something special on at Workington. The idea was taken to management saying anything they could do, we could do better! Eventually approval was from those that make these major decisions, probably emanating from the the inner sanctums of Carlisle Citadel station.

With the approval to go-ahead, an all grades committee was formed, a secretary elected and a date was duly set. We were placed under the watchful eye of the organiser of Carlisle's Open Days, so knowing this we decided to shoot for the moon, writing to the curator of the N.R.M. York asking if they would loan to us the recently preserved and restored Deltic 55002. Other requests were made which led to the presence of 1041 Western Prince from the East Lancs Railway, steam locomotive 850 Lord Nelson from the then operative Steamtown at Carnforth, plus quite a few other oddities. Also asked for was 45043 The King's Own Royal Border Regiment, a regiment with local connections, which to my surprise turned up spick-and-span!

In addition to the locomotives mentioned above also on display on Saturday September 10th were 20189, 26031, D200, 40155 & 40170. Additional exhibits included were British Nuclear Fuel's 0-4-0ST No.1, delivered by road; British Steel Corporation's fairly new Hunslet 0-6-0D.H. 403 which arrived under its own power; a 2'6" gauge Hunslet and rolling-stock from the R.N.A.D at Broughton Moor (Buckhill dump); the Ravenglass & Eskdale Railway 15" gauge steam locomotive Synolda, static on the back of a lorry.

The request for an A.C. Electric was declined, there was concern about the restricted loading gauge between Carlisle Currock and Maryport; also because it may have inspired hope that the route would be electrified in the near future! Unfortunately for the organising committee the day proved to be overcast and wet, which no doubt affected the attendance.

After the event the locomotives and other exhibits made their way back to their respective homes. I had wanted to go to Bury with Western Prince, but the presence of 55002 was a thorn in my side, comments made by my boss that cannot be printed here said amongst other things: 'Take that thing back to York, You wanted it, You got it, You take it back'! So on Tuesday 13th a Class 25 was attached to 55002 to begin its journey back to York. After a short delay we left Workington at 07.20. It was the second-man's job to tie the two locomotives together, the air & vaccuum pipes were connected but the heavy coupling was overlooked. The second man had recently been given a right good telling off for trying to enter the cab of Western Prince by kicking the cab doors when they were locked! So there was much abuse hurled about when the Class 25 moved off and not surprisingly damaged the vacuum pipe connection.

A couple of spanners were 'borrowed', the vacuum pipe reattached, and this time the couplings were connected and then we were off to Carlisle Kingmoor as a Class 8 freight. At Kingmoor the Class 25 was removed and lo and behold the spick and span 45043 coupled on. The Peak had left Workington on the Sunday light engine, making me wonder why all the fuss had been made about it returning to Kingmoor so quickly.

We left Kingmoor about 11.00 arriving at Tyne about 14.00. Here I was supposed to sit with the Deltic until 03.00 the following morning!! As the day wore on my liking of the Deltic was rapidly diminishing. By 20.00 that evening I decided I didn't like Deltics anymore and promptly cleared off for a pint in the Newcastle Railway club, followed by a couple more in the Gateshead club, then Gateshead shed and a couple more, then back to Tyne Yard. We left here around 04.00 for York, after train brake problems we sat for another few hours at York North Yard until 10.30 when I was able to hand responsibility for 55002 back to the late John Bellwood, then Chief Engineer at the N.R.M. York. It was then off to the canteen of the B.R.E.L. Works for some badly needed lunch, which was most enjoyable. My return to Workington was via Newcastle and Carlisle. I've not been particularly fond of Deltics since then!

Visitors to Workington

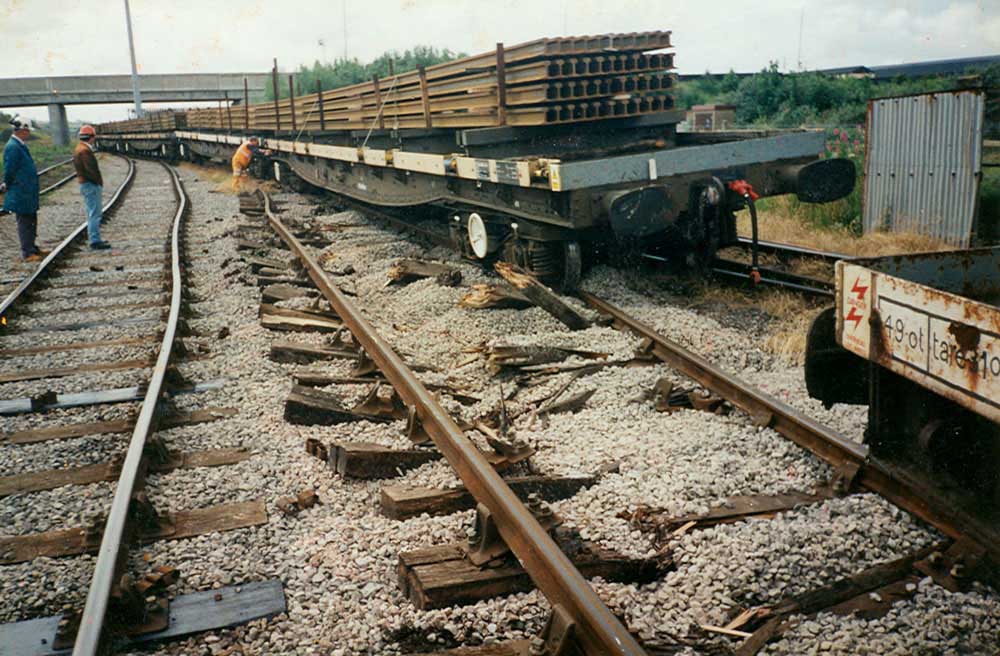

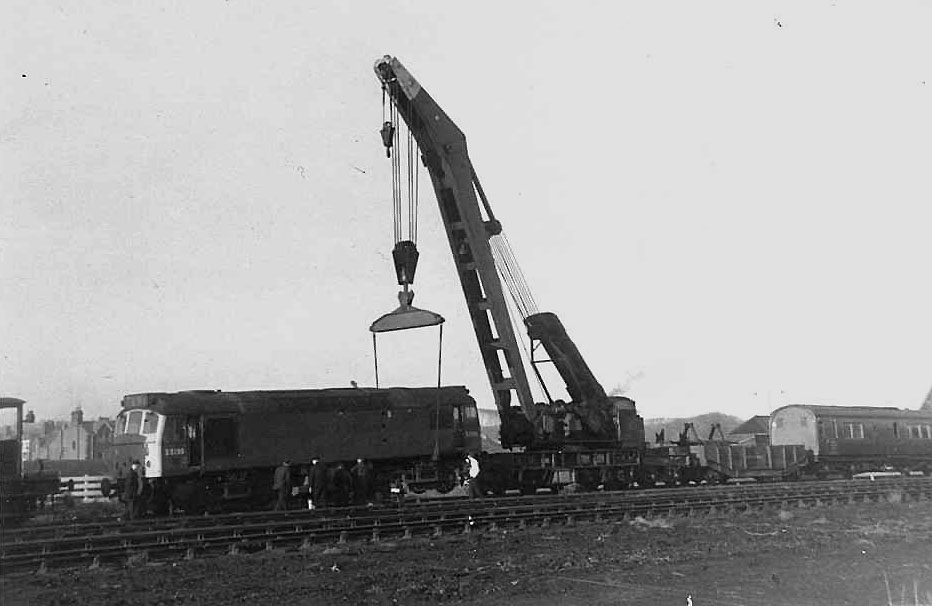

Derwent Derailment

Unusual Loads

The huge industrial complex in the Workington area did on occasion generate some large out-of-gauge loads for delivery to other parts of the country. The end use for these loads were generally not for the railways, the one exception might be the lengthy sections of continuously welded rail. Distington Engineering (later Corus Cumbria Engineering) did produce some huge ingot moulds destined for other B.S.C. companies, usually in the Sheffield & Scunthorpe areas. These moulds travelled on specially built 'Weltrol' wagons some of which were allocated to the Workington area. In particular Ian remembers an LMS built 120 ton carrier numbered M17000 and scrapped late in the 1970's.

The rail plant didn't generate the out-of-gauge loads until the early 1980's when the plant started producing 120' (36m) flat bottomed rail. They were originally subject to exceptional load conditions since multi-wagons loads were relatively untried. These loads were later eased and allowed to travel under load examined conditions, one result of this avoided the payment of large pay raises to a number of rail staff responsible for preparing these trains. In the 1990's BSC bought BR's welding plant at Redbridge and brought the plant up to Workington. Initial orders were for 600' rail lengths for the Channel Tunnel, later lengths were increased to 720' (216m) for general rail use, and continued to travel under load examined conditions.

Siddick Junction - Calva - Broughton Moor RNAD (Buckhill)

About a mile and a half north of Workington station was Siddick Junction. This junction provided the connection to the RNAD facility at Broughton Moor.

In the views below ex-works 25142 is in charge of the 6T42 loaded ammunition train from Broughton Moor RNAD to Workington yard for onward movement to Carlisle. At one time Calva Junction was a busy place on the former Cleator & Workington Junction railway between Workington, Siddick & Seaton. This mainline closed in 1964 with only a few isolated parts remaining open after this. The Calva remnant was the last to close, during 1992. Ian remembers this short branch was a difficult one to work with some gradients as severe as 1 in 70. And the condition of the track in the views below suggest speeds would not be high!

25142 was present at Derby Works from August 1978 to January 1979 so possibly the views below are from sometime in January or February 1979.

In the above views of 25142 at Calva the train has arrived from the RNAD facility and will now reverse its loaded ammunition train down to Siddick Junction where it will then proceed on to Workington yard. These moves could be quite hair raising particularly with the 1 in 70 ruling gradient. Ian remembers a heated and protracted debate with a senior supervisor concerning the need for a brake van on these trains. The rulebook said that for trips under five miles a brake van was not necessary, but no mention was made of the propelling moves! Delving into the sectional appendix provided the answer, the mileage was 5 miles 79 chains each way!

Lowca Lane Crossing

The three views below, all from the camera of Ian Marsh, show two Class 25's on engineering duties providing support for repairs to the seawall between Siddick & Flimby. The date is believed to be 1977 and the line between Carnforth and Maryport had sustained considerable damage from several storms. The width of the rocky beach in the left picture makes it obvious that it must have been a strong storm to be able to push the sea up to the low embankment supporting the tracks.

Maryport

Dalston (Oil Sidings)

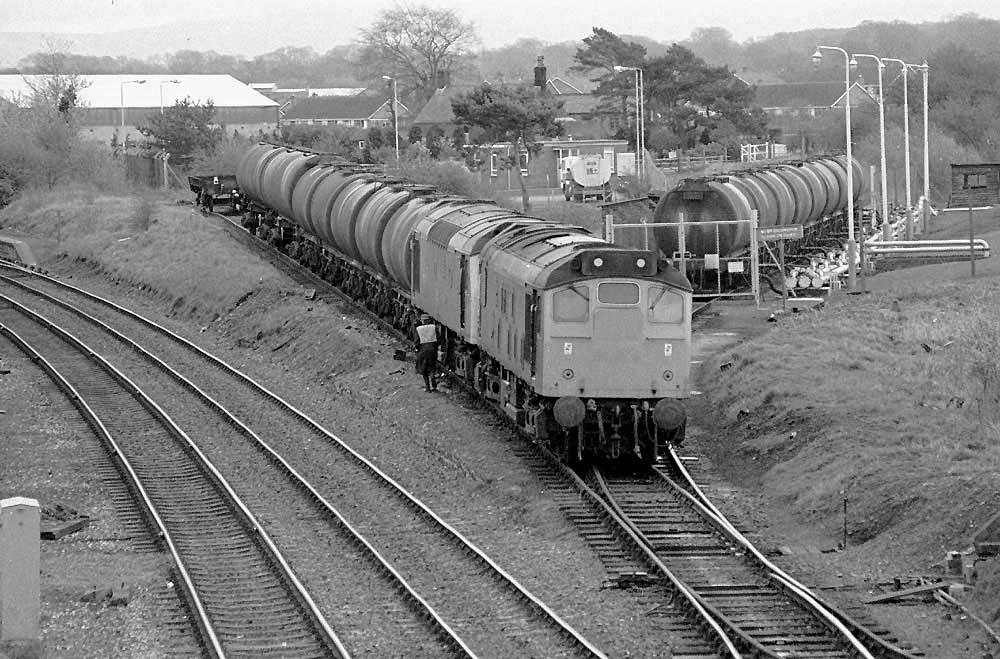

During the late 1970's five or six trains a week were received at the Shell-BP depot. Motive power was usually a Class 40, but any LMR allocated Type 2 or 4 or ER Class 37 could show up. The oil trains originated from Teesport.

Page last updated October 26th 2016