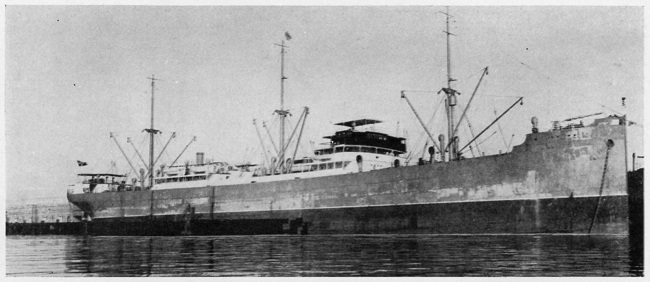

At the time of its commissioning the Handicap was the largest vessel built in Norway.

In 1916 a vessel was ordered for A/R Vestlandske Lloyd (Brødrene Olsen), Stavanger with the intended name T/S Rosenberg, however the contract was sold in 1920 to Bruusgaard Kiøsteruds D/S A/S (Bruusgaard Kiøsterud & Co.), Drammen and changed to a motorship. Construction eventually commenced at the yard of Rosenberg mek. Verksted in Stavanger, with delivery taking place in January 1922 with the ship now named Handicap.

1921 December 14th: completed sea trails around Stavanger.

1921 December 24th: departed Stavanger for Newport to load 7,760 tons of coal for Bahia Blanca: details

Stavanger to Newport 980 miles

Newport to Bahia Blanca 6,390 miles

Mean speed of ship 10.25 knots

Daily fuel consumption 9.4 tons

Daily lubricating oil consumption 24.3 gallons

The return trip was completed with a full load of grain, with the ship encountering strong winds and heavy seas throughout the whole voyage, particularly on April 3rd & 4th 1922 when the speed was reduced to 8.75 knots.

Bahia Blanca to Hamburg 6,943 miles

Mean speed of ship 10.00 knots

Daily fuel consumption 10.2 tons

Daily lubricating oil consumption 22.2 gallons

The fuel consumption included that consumed by the main engines and the auxiliaries.

1922 May 15th: the Handicap arrived at Port Arthur, Texas in ballast from Hamburg under Captain Gustav Sundaa & Chief Engineer Holms to load a full cargo of Texas Company case oil (228,000 cases?) for Hong Kong via Panama. Whilst at Port Arthur several marine engineers, eastern ship owners & shipbuilders inspected the Sulzer two cycle diesel engines, being interested in some of the novel features built into the engines.

An inspection of the cylinder heads after five months of service, as required by the Norwegian Board of Control required only minor grinding of valves and adjustments, the cylinders and combustion chamber parts were clean and the wear of rubbing surfaces extremely small. Operating problems had been minor, air pockets in the fuel line had caused a stoppage at sea enroute to South America and a safety gasket had blown out on the trip from Hamburg to Port Arthur.

In January 1937 the Handicap was sold to Ringdals Rederi A/S (Olav Ringdal), Oslo and was renamed Ringar.

1937 July 6th: at Port Adelaide to unload approximately 5,500,000 super feet of logs and cut timber from Vancouver for the Adelaide mills, reportedly the largest load of such lumber received on one vessel. The Ringar would then to sail to Port Pirie on July 16th to load lead & zinc concentrates for the United Kingdom via Cape Town. Shortly after departing Port Adelaide in ballast, the port propellor lost a blade. The ship returned to the Outer Harbour for repairs, using one of the ship's spare blades, now with an expected departure on July 19th. The fitting of the new 3,000lb blade to the boss required working on thirteen huge studs & nuts. Because the ship was in ballast, by flooding the forward holds and shifting forward 350 tons of fuel, the stern was raised enough to allow repairs to be made from a punt, a diver not being needed. Rain would delay loading of the concentrates, being completed on July 26th for a total of 3,000 tons of lead & 5,091 tons of zinc concentrates.

1937 August 1st: at Fremantle to bunker fuel.

1937 August 27th: at Table Bay.

1937 September 11th: at Dakar.

1937 September 23rd: at Avonmouth.

1937 October 1st: at London.

During April 1940 the Ringar became part of the Norwegian Home Fleet.

At the end of World War II the Ringar was at Tonsberg. It was sold in July 1946 to Decker & Montemurro Ltd., Buenos Aires, Argentina and renamed the Clelia Decker.

It was sold in 1949 to Incomfin, Zürich and renamed Melide (Panamanian flag?).

Sold in 1951 to Anstalt Melide (Italnavi Soc. di Nav. SpA), Panama.

Sold during 1953 to San Antonio SA (Cia. Armatoriale Italiana SAS, Venice), Panama. In 1953 a 7 cylinder 2T DV DM (Sulzer Brothers, Winterthur) diesel engine was installed producing 3,300 bhp.

Sold in 1957 to Overseas Enterprises Inc. (Soc. di Gestione Marittima e Commerciale SarL, Trieste), Panama and renamed Montreux. Arrived Kaohsiung on March 10th 1967 for scrapping.

Main Engines

The four cylinder engines have the injection air compressor as an integral part of the engine. Electrically driven turbo-blowers provide scavenging air. The maneuvring station is located at the upper engine platform, allowing an unobstructed view of the engine room including valve gear & switchboard. The auxiliaries are handled on the lower grating. The engines can be operated at manuevring speeds as low as 25rpm. The thrust block is built as an extension to the main bedplate and is lubricated from the main engine's lubrication system. Although the main engines were built by Sulzer, Winterthur their general design is similar in all important features to the Busch-Sulzer marine diesels built by Busch-Sulzer, St Louis.

The Handicap was the first commercial vessel to have the scavenging air supplied by electrically driven turbo-blowers. Two turbo-blowers are fitted, one is sufficient to provide for both engines, the other is spare. They are located at the control station level at the forward engine room bulkhead, one each on the starboard & port sides, in compartments closed off from the main engine room. Air is taken from the deck above or from the engine room floor, the latter assisting in the ventilation of the engine room in hot climates. The blowers operate at 2,800 to 3,400 rpm by 220V DC motors, power consumption is about 4% of the total available from the main engines.

Exhaust gases from the main engines (approx 700F) are routed around the kitchen oven to provide a baking heat of 300F - 500F for the cooking needs of the crew. If the main engines are shut down an electric range is used.

Auxiliary Engines

Because there is no steam supply on the Handicap all electricity is supplied by the two auxiliary motor sets. Any one set can handle the entire needs of the ship, at sea one of the units handles the power for the turblo-blower (approx 110bhp), the engine room pumps, auxiliaries, steering engine and 'hotel' power for the needs of the crew. The total load at sea averages about 200bhp. When in port, with the main engines shut down one auxiliary set provides power for the ten Asea electric winches, any engine room requirements and the 'hotel' power. When at sea the power utilised by the winches provides the required reserve compressor capacity for emergencies, thus avoiding the need to instal a motor driven auxiliary compressor..

The surplus air is used for charging the eight starting and manouevring air tanks, each having a capacity of 28 cubic feet at 60 atmospheres. Air at any pressure (20 to 60 atmospheres) is utilised for starting and manouevring, the high pressure storage providing ample reserve capacity for extensive manouevring when entering port. A large supply of low pressure air (200psi) is carried in separate tanks to operate the manouevring motors on the main engines, the turning engines, the siren and other minor uses.

Details

Built: Rosenberg Mekaniske Verksted, Stavanger 1921

Launched: 1922

Tons: 9,000dwt (some sources 8,863dwt); 5,013 gross tons, 3,028 net tons

Length: 415ft (between perpendiculars)

Breadth: 54ft 6in

Depth: 36ft 11in (molded to shelter deck)

Draught: 25.4ft

Propulsion (to 1953): 2 x 4ST60 Sulzer Winterthur built diesel engines, each producing 1,350bhp at 100rpm (cyl 600mm x 1060).

Propulsion (from 1953): 1 x 7cyl Sulzer diesel engine producing 3,300bhp.

Auxiliary engines: 2 x 4SS31, each producing 330bhp at 210rpm and 1 x MC12 producing 12bhp at 450rpm (to power an auxiliary compressor?).

Weight of engines: 752,400lb (includes thrust bearings, flywheels, turbo-blowers, with motors, exhaust silencers, starting and injection air tanks).

Weight per brake horsepower of main engines: 278lb

Weight of auxiliary engines, with flywheels, silencers & air tanks but excluding electric generators: 136,400lb

Weight per brake horsepower of main engines: 50.3lb.

Screws: 2

Speed: 11 knots

Crew: 35

Sources

Sulzer List of Motorships approx 1933

Marine Engineering & Shipping Age August 1922 (VOL 27)

Pacific Marine Review Vol 18 October 1921

Page added May 30th 2011.

Last updated March 4th 2016.

Return to Ship menu

Return to site menu