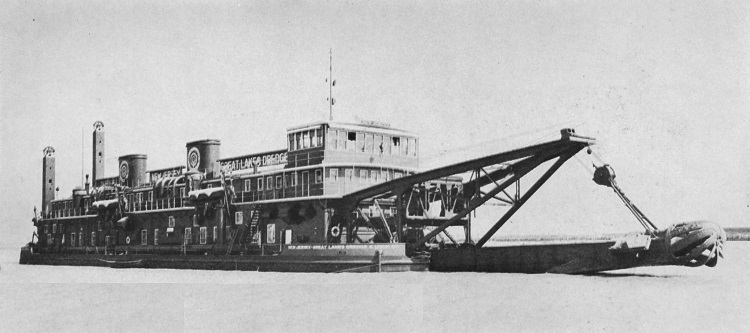

This vessel was built as a 30 inch diesel electric suction dredge by Manitowoc Shipbuilding Corporation, Manitowoc, Wisconsin for the Great Lakes Dredge & Dock Company of Chicago. The dredge machinery was built by the Bucyrus-Erie Company. The electrical equipment was provided by General Electric Company.

The dredge was constructed for use along the Great Lakes at a cost of approximately $2million and carried appointments more normally found on luxury passenger vessels. It has been described as the largest and most expensive contractors tool ever built.

In operation a huge revolving blade of vanadium-steel alloy loosened the material under water, the material to be discharged in semi-liquid form through big pipe lines. The intake was thirty four inches in diameter and located in the center of the cutter. A 600hp motor powered the cutter whilst a 3,000bhp pump sucked up the material loosened by the cutter. A thirty inch stream of material could be forced a distance of 10,000 feet.

Two eighty ton feet or 'spuds' propelled the New Jersey forward. When necessary to move the dredge one spud at a time was lowered creating a pivot on which the dredge turned. This spud was then raised and the second spud lowered with the process repeated as required. The spuds were only used for movement at a worksite, to transfer the dredge over long distances a special tug was constructed for towing purposes.

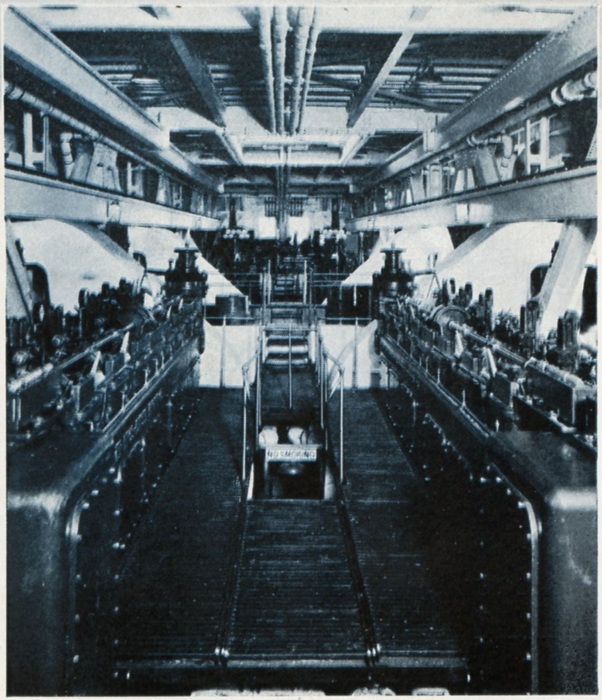

The electrical output of the four diesel engines had the capacity to illuminate a city the size of Albany N.Y. The dredge was equipped with fifty seven motors of varying sizes. A telephone system connected all parts of the dredge, including to the end of the pipeline which may be over a mile away. The forward control room overlooked the cutter and was equipped to allow the operator to monitor the depth of the excavation being made, make changes to the cutter speed and pump flow. The diesel engines could also be monitored from this position.

The dredge could operate 24 hours a day, with three shifts comprising 40 - 52 men. The crew were housed in quarters equipped with electric fans, showers & bathrooms, a social room, dining hall, kitchen & laundry.

During 1929 the New Jersey was used in the filling-in of Chicago's Lake Shore, dredging material from offshore, transferring it via pipeline to build-up the lakeshore.

During July 1930 the New Jersey was hired from? Dunbar & Sullivan Dredging Company by the City of Detroit, Department of Water Supply to excavate material from a river channel to provide an intake system for additional water supply.

On May 27th 1932 whilst dredging the Keweenaw Waterway, Michigan the New Jersey dredged up a 490 pound piece of float copper. The copper is native metallic copper almost chemically pure and presumed dislodged and transported by glacial action, fragments of this size are rare. The contractor, Zenith Dredge Company presented it to the United States Engineers Office, Duluth, who had contracted for the use of the dredge.

In August 1966 the location of a new joint Army-Navy military complex was planned for a marshy area alonside the My Tho River at Dong Tam, South Vietnam eight kilometers west of the town of My Tho and sixty-five kilometers southwest of Saigon. The works included excavation of a rice paddy for development into a turning basin and dredging an entrance channel into the basin from the My Tho River. Sand was also to be dredged from the river, creating a landfill of one square mile and providing a stockpile for airfield, concrete, and road construction projects in the surrounding area. The 16-inch pipeline cutterhead, Cho Gao, first of five dredges assigned, started work on August 4th 1966 with the basin and channel projects completed in April 1967. The shortage of sand at Dong Tam persisted.

The dredgers drew the attention of the enemy and were frequently targeted by Viet Cong sappers. The Jamaica Bay, a 30-inch pipeline cutterhead dredge, was sunk on January 9th 1967, causing the loss of two American crew members. The Jamaica Bay was salvaged, but while under tow off the port of Vung Tau, heavy seas were encountered leading to the sinking of the dredge. Attempts to raise the dredge failed. The loss of the Jamaica Bay was made good by the New Jersey, which was also serving in South Vietnam.

On July 28th 1968 the Thu Bon 1, a 12-inch pipeline cutterhead dredge was sunk by sappers whilst working in the entrance channel. Although salvaged the repair costs were judged uneconomic, the dredge being scrapped for parts. She was replaced by a similar 12-inch dredge, the Thu Bon 11.

On September 22nd 1969 the U.S. Navy-owned 27-inch pipeline cutterhead Sandpumper sucked up live ordnance from the bottom of the My Tho River and sank following detonation of the explosive. Attempts were made to raise the dredge, but a survey revealed that salvage and repair costs were again uneconomic. The Sandpumper remains on the bottom of the My Tho River, being no immediate threat to navigation.

On November 22nd 1969 the 30-inch pipeline cutterhead New Jersey was sunk by sappers. Tugs were able to pull the dredge to shallower waters of the river, coming to rest in four feet of mud.

The explosion caused severe damage to the inboard and forward bulkheads of the starboard spudwell, with many holes, cracks, split seams and wrinkles in this area. A large section of the spud well pontoon was blown off. The blast also tore a large hole in the hull underneath the sternmost compartment. The dredge's engineering spaces were flooded to the waterline. The Harbor Clearance Unit One, a U.S. Navy team from the Subic Bay Naval Base were tasked with raising the New Jersey. Existing conditions indicated a salvage plan for patching and pumping to produce buoyancy necessary to raise the dredge. Three 3-inch, three 6-inch and one 10-inch pumps were used throughout the process, either in combination or intermittently.

In the initial phase the three most seriously damaged compartments were ignored, with the sealing of hatches, ports, passageways and other openings, along with patching of other holes and leaky areas between the forward bulkhead of the aftermost compartment and following the high water line to the machine shop bulkhead. three 6-inch pumps and the 10-inch pump were employed, leading to a two to three foot drop in the water level. At this point pumping was stopped to allow the opening of the watertight doors between the pumpwell and adjoining spaces. Pumping continued but was stopped during high tides. Holes uncovered by the lowering water level were plugged, some areas were patched with concrete and fifteen tons of topside materials were removed.

The New Jersey broke free from the river bottom, rose slightly and developed an 8-degree port list. Following the current plan would have made the list worse. Controlled flooding was used to help determine the cause of the list. A modified plan put in place was not successful, each time the port list occurred, despite the use of a variety of pump combinations. Eventually all pumps were used at full capacity (two 6-inch pumps, one port, one starboard; two 10-inch pumps on the pumpwell; three 3-inch pumps in the engineering spaces, with blowdown operations on the port and starboard fuel tanks). Four hours later the dredge broke free of the bottom with a slight starboard list. Seven hours later, on December 30th 1969 the dredge was afloat at a 2-degree starboard list, with mean draft measured at 14.5 feet.

In January 1970 the dredge was taken to Singapore for overhaul and repairs in the Keppel Yards. The New Jersey was towed back to South Vietnam in May 1970, refitted with the gear that had not been taken to Singapore, and put back in operation performing maintenance dredging at Qui Nhon.

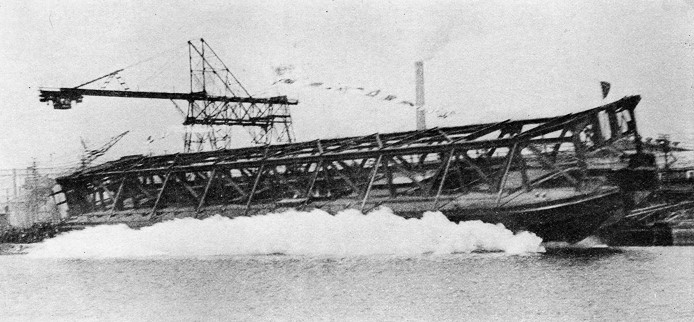

Builder: Manitowoc Shipbuilding Corporation, Manitowic, Wisconsin: Hull No. 228

Launched: 1927

Length: ??

Beam: ??

Depth: ??

Gross Weight: ??

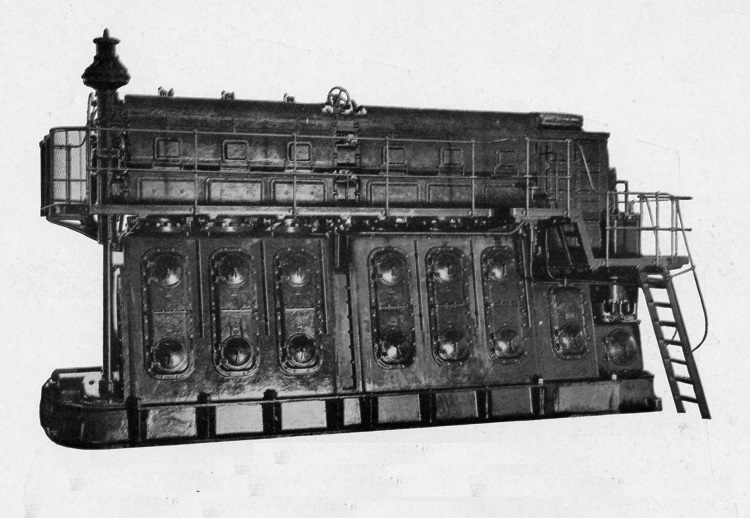

Engines: Four single acting 2-cycle crosshead Busch-Sulzer Type 6 CE-17 1,150bhp engines totalling 4,600 hp at 200rpm(?)

Screws: ?

Sources

Popular Mechanics December 1929 pp 952-953

Busch-Sulzer Bros Diesel Engine Co. publicity material (Jan 1930?)

Vietnam Studies Base Development in South Vietnam 1965-1970 by Lieutenant General Carroll H Dunn 1991

Page added October 22nd 2015.

Last updated February 15th 2025.

Return to Ship menu

Return to site menu